Phase-change temperature-control type high-voltage cable

A high-voltage cable, phase change temperature control technology, applied in the direction of insulated cables, cables, power cables with shielding layer/conductive layer, etc., can solve the problem of excessive temperature rise of cables, high thermal resistance, unfavorable heat dissipation and cooling of cable conductors, etc. problems, to achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

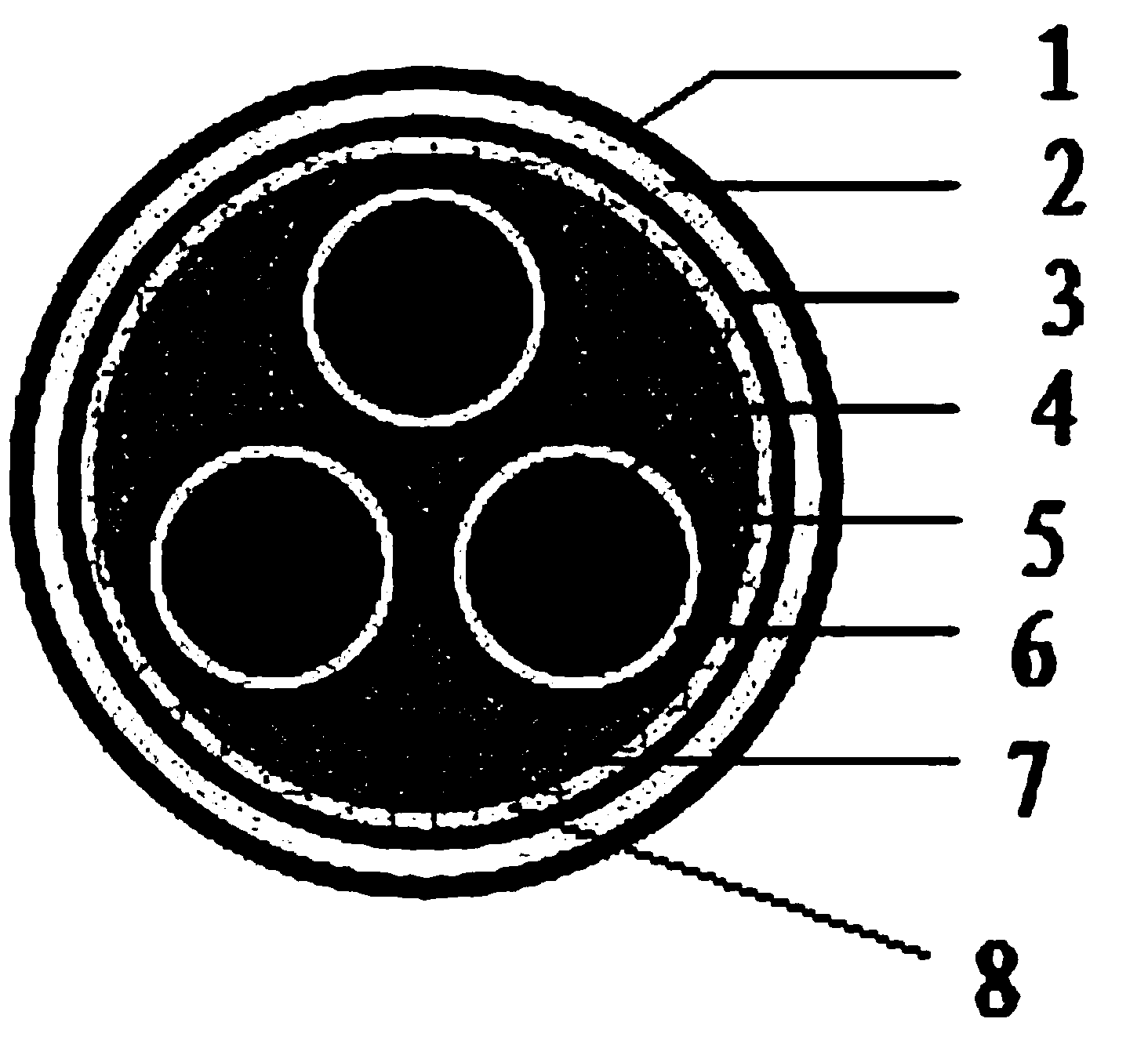

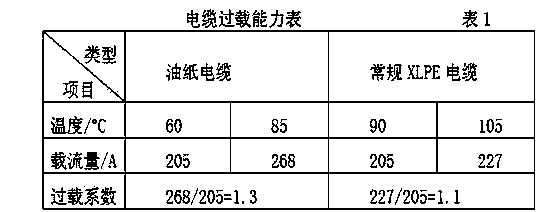

[0020] The invention optimizes the filling material of high-voltage cross-linked polyethylene cables based on the organic composite phase change material, and proposes a self-cooling filling material with strong heat conduction. While increasing the thermal conductivity and reducing the thermal resistance of the filling layer, the transient temperature rise of the high-voltage cable can be effectively reduced by taking advantage of the large heat capacity of phase change cooling. Thus, thermal breakdown caused by long-term cycle local overheating of the high-voltage cable is prevented, and the service life of the high-voltage cable is effectively extended. Not only that, the use of heat conduction-enhanced composite phase-change materials can also greatly improve the heat conduction efficiency of the filling layer, combined with phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com