Alloy type thermal fuse with high ampere capacity

A technology of temperature fuse and ampacity, applied in the direction of heating/cooling contact switch, etc., can solve the problem of thermal protection of the power battery that cannot have a large capacity, and achieve the effect of high ampacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

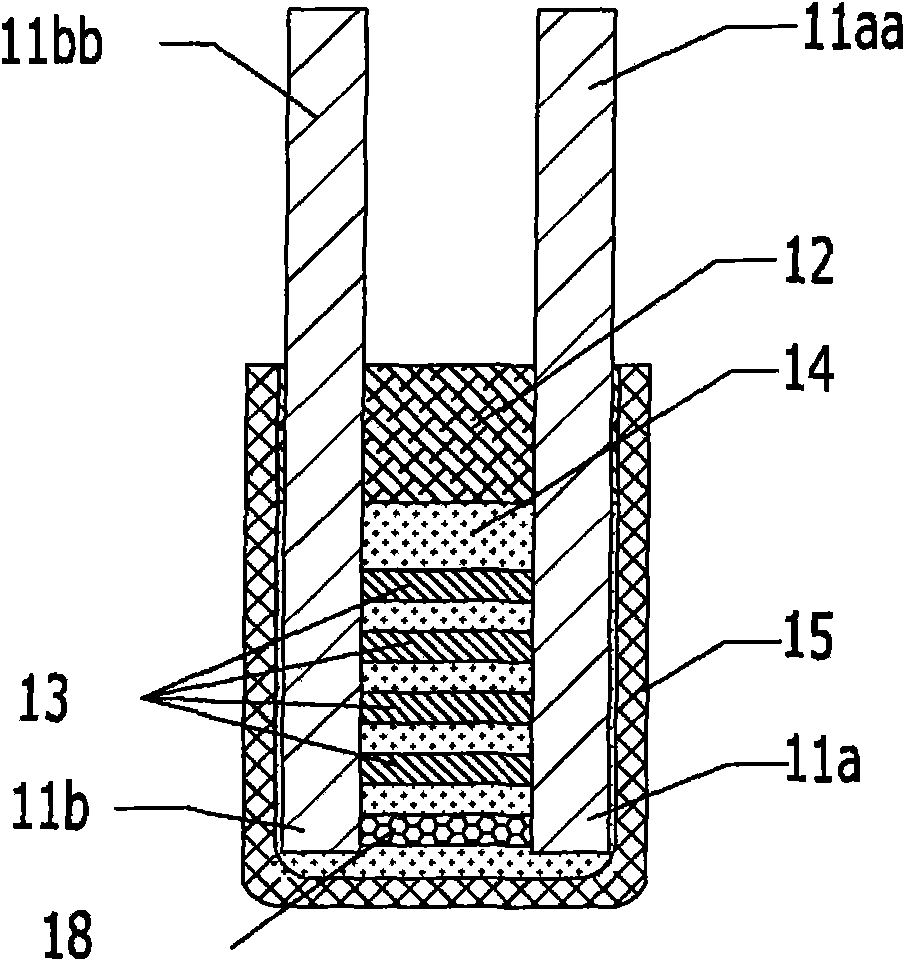

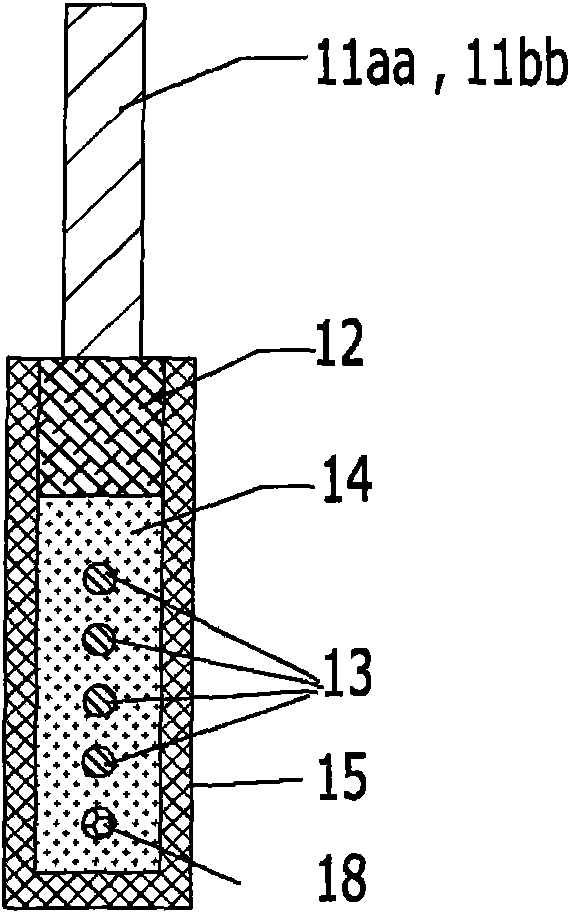

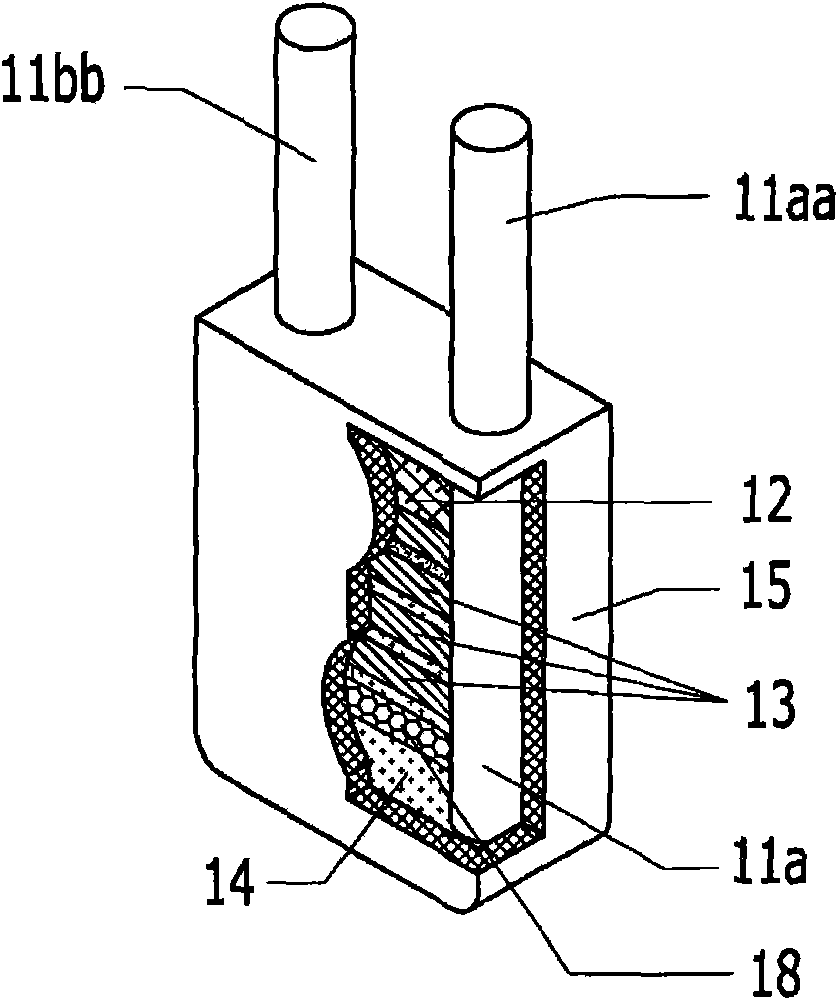

[0018] Specific embodiment 1, the present invention will be further described below in conjunction with accompanying drawing 1, accompanying drawing 2 and accompanying drawing 3 and specific embodiment, wherein, stated is in order to illustrate the preferred specific embodiment purpose of the present invention, rather than for Limit the above purpose. Accompanying drawing 1, accompanying drawing 2 and accompanying drawing 3 are respectively the front sectional view, the side sectional view and the three-dimensional anatomical view of the high ampacity alloy type thermal fuse of the preferred specific embodiment of the present invention. In the described embodiment, the high ampacity alloy type thermal cutoff includes a casing 15, and an assembly consisting of the following parts is assembled in the casing 15: There are two conductive and thermally conductive metal electrodes 11a and 11b, In this embodiment, the conductive and heat-conducting metal electrodes are in the shape o...

specific Embodiment approach 2

[0019] Specific embodiment 2, below in conjunction with accompanying drawing 4, accompanying drawing 5, another kind of specific implementation of accompanying drawing 6, the present invention will be further described, wherein, accompanying drawing 4, accompanying drawing 5 and accompanying drawing 6 are respectively this The front sectional view, side view sectional view and three-dimensional anatomical view of the high ampacity alloy type thermal fuse of the specific embodiment, in the described specific embodiment, the alloy type thermal fuse of the high amperage capacity comprises a shell 15, in An assembly composed of the following parts is assembled in the housing 15: there are two conductive and heat-conducting metal electrodes 11a and 11b. There are a plurality of through holes in the array, and the positions of the through holes on the two electrodes are completely consistent. There are many low-melting point alloy wires 13a, 13b passing through the through holes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com