Intensive busway

A busway and intensive technology, applied in the direction of cooling busbar devices, semi-closed busbar devices, etc., can solve the problems of insufficient pressure on the socket of the pin assembly, damage and deformation of the pin assembly, and the carrying capacity can not meet the requirements, etc., to achieve a simple structure , Enhanced pressure, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

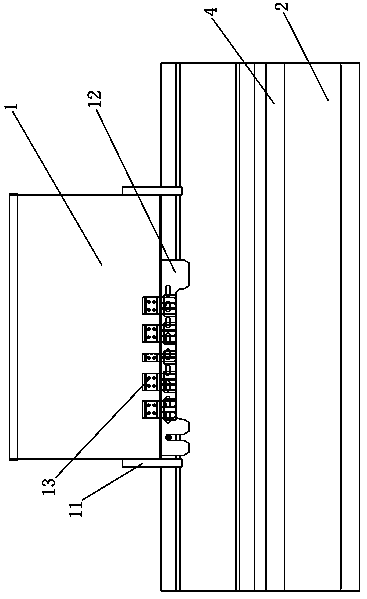

[0036] Such as figure 1 , figure 2 As shown, the present invention includes a plug box 1, two bus duct shells 2, and five bus bars 3;

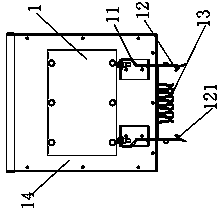

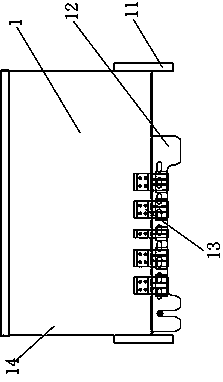

[0037] Such as image 3 , Figure 4 As shown, the plug box 1 includes a box body 14, two pairs of guide plates 11, a fixed plate 12, and 5 pin assemblies 13; There is a pair of guide plates 11, and each pair of guide plates 11 on the same side is arranged symmetrically; the fixed plate 12 is a part with a "┗┛ shape" in cross section, and its middle part is fixed on the bottom surface of the box body 14. There is an "L-shaped" structure 121; such as Figure 8 , Figure 9 As shown, the pin assembly 13 includes a pin 131, a pair of reeds 132, and a pair of pin copper sheets 133. One end of a pair of pin copper sheets 133 is symmetrically arranged on the bottom surface of the pin 131, and the outer contours of the pair of reeds 132 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com