Special tensile dragging control cable and method for manufacturing same

A technology for controlling cables and manufacturing methods, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve problems such as unfavorable industrial expansion and reproduction, affecting production efficiency, and uneven stress, achieving good elasticity and improving use. Longevity, easy bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

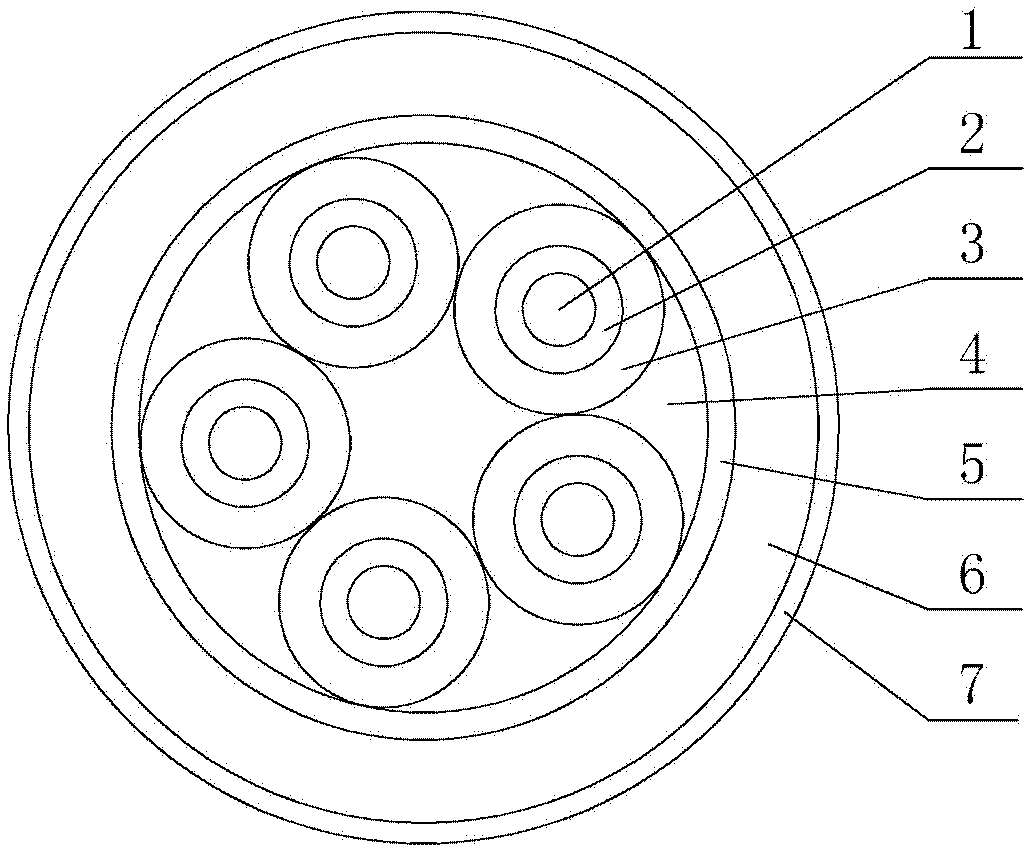

[0034] Embodiment: Referring to Fig. 1, the special tensile and dragging control cable of this embodiment is composed of multiple stranded galvanized soft steel wires 1, tinned oxygen-free copper wires 2 and insulating extruded cladding 3 to form an insulated wire core. The insulated wire cores are twisted into a cable core, and the filling layer 4 composed of hemp rope is filled in the gap between the cable cores. The cable core is overlapped and wrapped with a tear-resistant polypropylene tape 5 and extruded with a tensile and wear-resistant polyurethane elastic sheath 6. The outermost layer of the cable is the outer sheath of braided galvanized steel wire 7;

[0035] The insulated wire core is composed of multi-strand galvanized mild steel wire 1 as a reinforcing core and tinned oxygen-free copper wire 2 as a copper conductor, and the insulating extruded cladding 3 is composed of EPDM composite rubber.

[0036] The manufacture method of cable of the present invention, carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com