Steel-pipe-insertion local strengthening trenchless repair method for drainage pipeline with large pipe diameter

A drainage pipe, local reinforcement technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of small construction distance, unsuitable for deep buried pipeline repair, high construction cost, etc., to achieve convenient construction, The repair price is cheap and the effect of saving repair materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

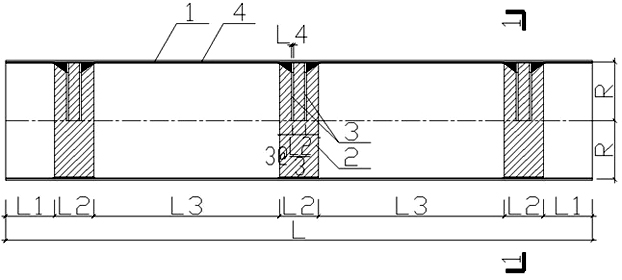

[0021] Assume that the length of a certain pipeline to be repaired is L=6m, and the diameter of the pipeline is DN1200. The implementation process is as follows:

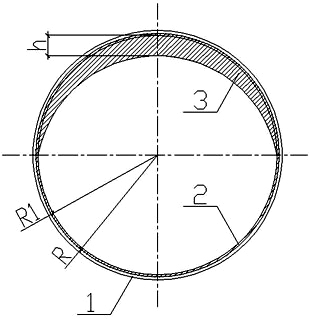

[0022] 1. According to the pipe radius R=600mm of the pipeline 1 to be repaired, the wall thickness R-R1=10mm of the inserted steel pipe 2, and the material parameters of the two pipelines, calculate the size, quantity and arrangement of the inserted steel pipe 2 and the crescent rib 3 spacing.

[0023] 2. Clean the pipeline 1 to be repaired, and conduct a CCTV (Closed Circuit Television) pipeline endoscopic television detection system inspection.

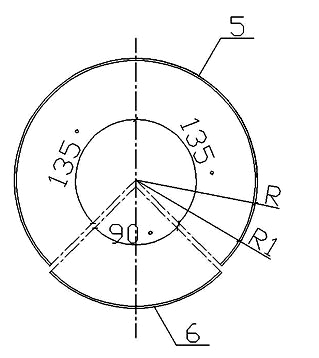

[0024] 3. Manufacture of 90-degree fan-shaped steel pipe blank 6: roll (R-R1) mm thick steel plate into a 90-degree fan shape (see the inserted steel pipe image 3 the lower side), the radius is R1=590mm, and the length is L2=400mm.

[0025] 4. Production of 270-degree fan-shaped steel pipe blank 5: roll (R-R1) mm thick steel plate into a 270-degree fan shape (see the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com