Clasping device for fitting up steel pipe sleeve and construction method thereof

A clamping device and sleeve technology, which is applied in the field of holding clamping devices for steel pipe casing groups, can solve the problems of uneven speed, damage to support brackets, etc., and achieve the effects of uniform speed, simple device, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

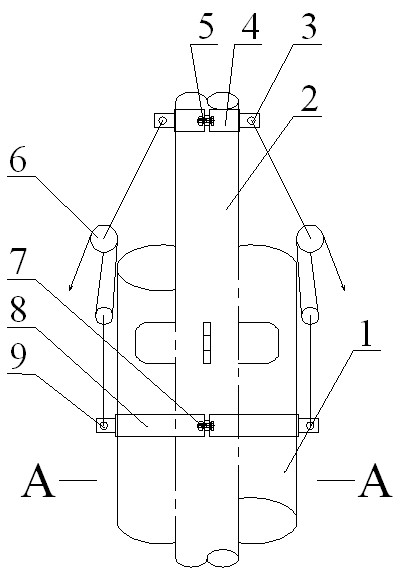

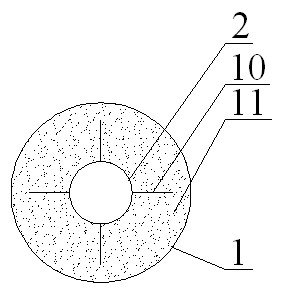

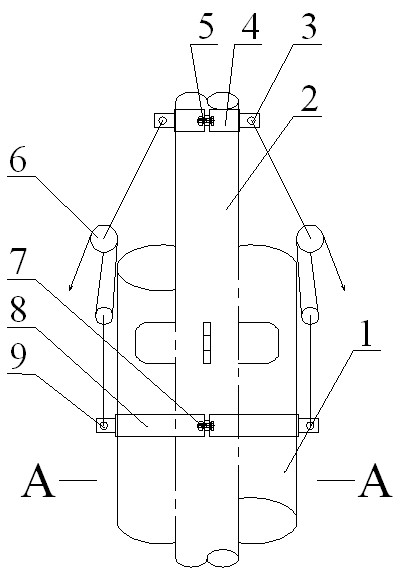

[0015] A clamping device for pairing of steel pipe casing groups, comprising an inner tube clamp 4 and an outer tube clamp 8, the inner tube clamp 4 is fixed by fastening bolts Ⅰ5, the outer tube clamp 8 is fixed by fastening bolts Ⅱ7, and the inner tube clamp 8 is fixed by fastening bolts Ⅱ7. Two symmetrical hoisting holes I3 are provided on the pipe holding card 4, and two symmetrical hoisting holes II9 are provided on the outer pipe holding card 8, and the lifting device 6 is installed on the lifting holes I3 and II9.

[0016] The lifting device is an electric hoist or a manual hoist or a pulley block.

[0017] The construction method of the clamping device for the steel pipe casing group pair has the following steps:

[0018] (1) Install the outer casing between the two valve wells, then fasten the outer pipe on the outer casing, and install one end of the lifting device on the hoisting hole II where the outer pipe is held;

[0019] (2) Assemble the first section of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com