High-temperature oxygen corrosion resistant stainless steel, high-temperature oxygen corrosion resistant stainless steel casing pipe and manufacturing method of high-temperature oxygen corrosion resistant stainless steel casing pipe

A manufacturing method and oxygen corrosion technology, applied in the field of casing and its manufacturing, stainless steel, can solve the problem of not meeting the requirements of 500 ℃ fire flooding corrosion resistance and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17 and comparative example 1-7

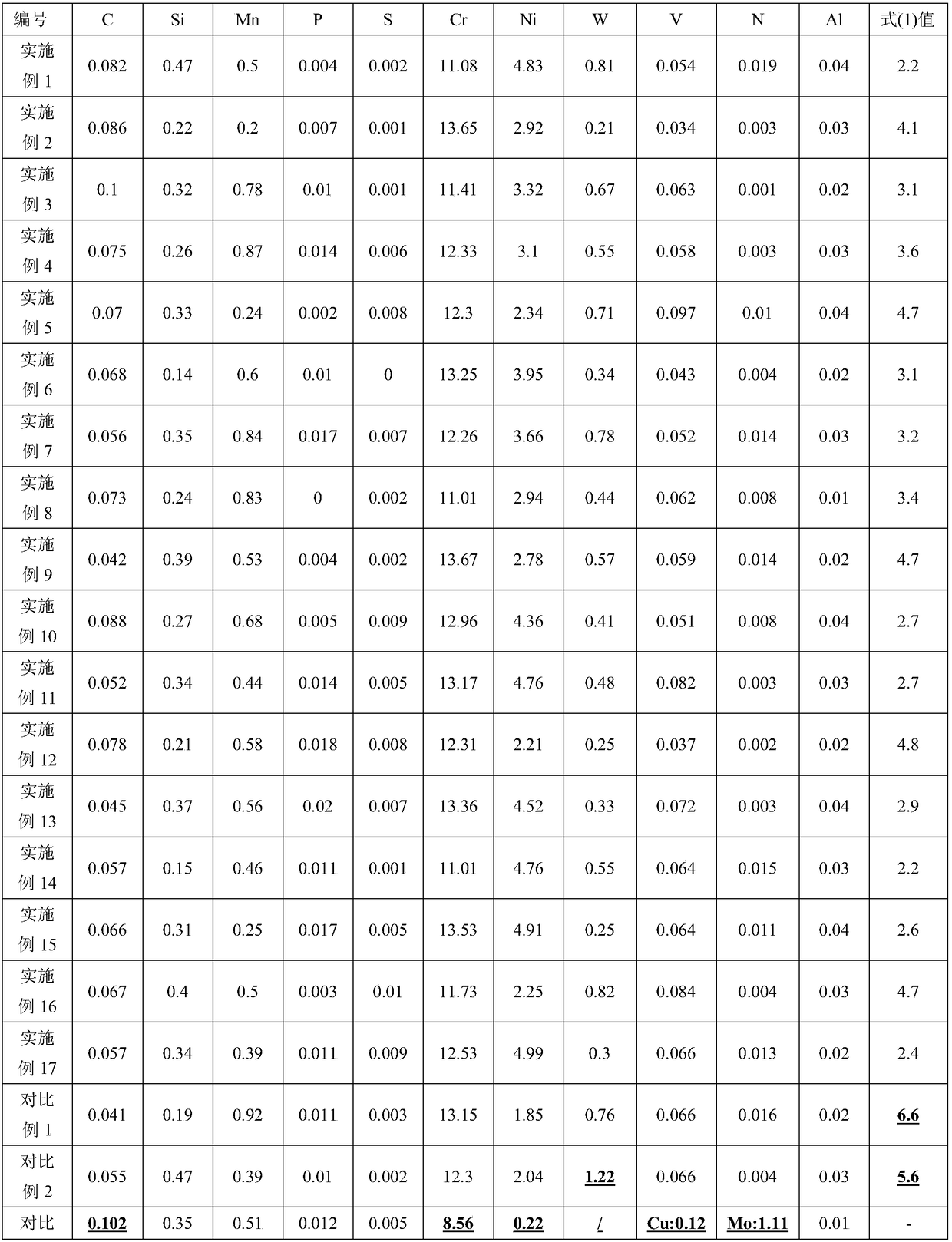

[0043] Table 1 lists the mass percentage of each chemical element in the high temperature oxygen corrosion resistant stainless steel of Examples 1-17 and the comparative steel of Comparative Examples 1-3.

[0044] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except P and S)

[0045]

[0046]

[0047] Note: The value of formula (1) in the table refers to the value calculated by (Cr+1 / 2W):(Ni+5C), where Cr, W, Ni, and C are the mass percentage content of each element.

[0048] The high temperature oxygen corrosion resistant stainless steel of Examples 1-17 and the comparison steel of Comparative Examples 1-7 are smelted, casted, rolled, rolled, sized, tempered, and the process parameters involved in the sizing step and the tempered step Listed in Table 2.

[0049] In the sizing step, control the final rolling temperature at 900-980°C, and then perform rapid cooling at a cooling rate of 15-40°C / s, control the final cooling temperature of rapid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com