Jacking pipe construction method for trimming deviation by reverse jacking of steel pipe casing

A steel pipe sleeve and jacking technology, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, pipes, etc., can solve the problems of complicated deviation correction procedures, high construction costs, and pipeline earthwork collapse, etc., to increase the overall strength. and damage resistance, reduce construction costs and material costs, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

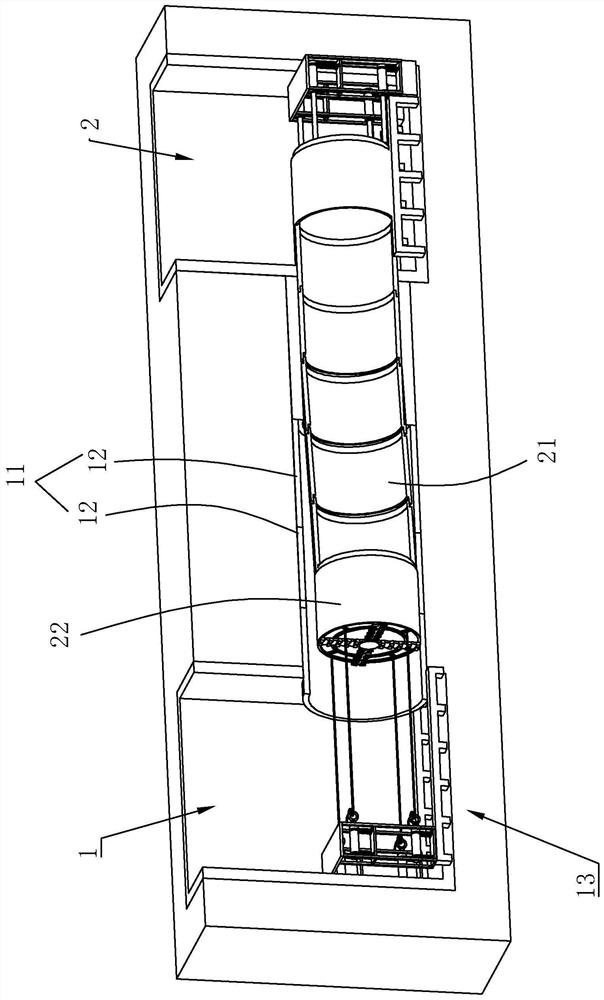

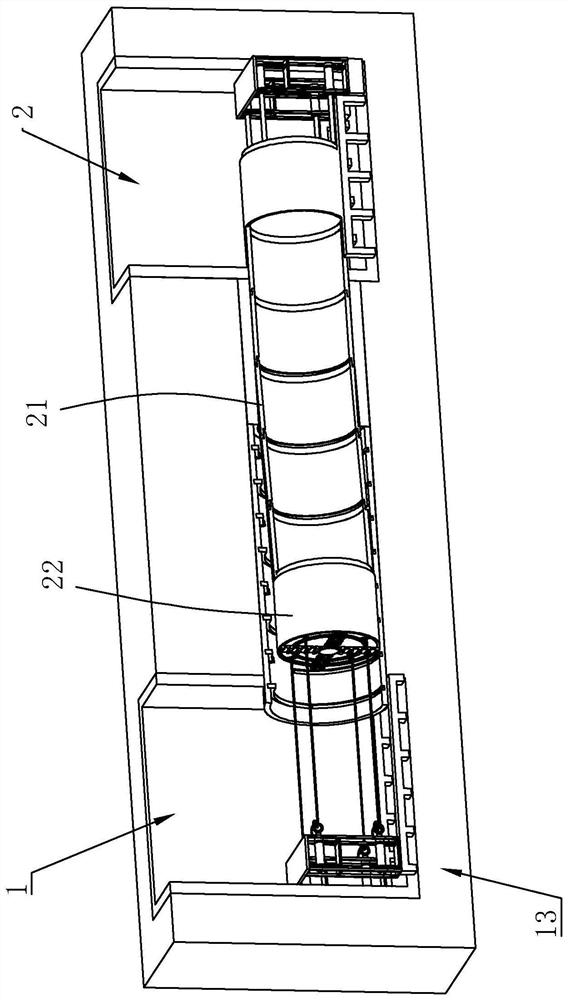

[0043] Such as Figure 1 to Figure 2 As shown, the reverse jacking steel pipe sleeve trimming offset pipe jacking construction method disclosed by the present invention includes the following steps:

[0044] Step 1: installing jacking equipment 13 in the receiving well 1 and prefabricating a steel casing 11 with a diameter larger than the concrete pipe 21;

[0045] Step 2: In the receiving well 1, according to the conventional initial pipe jacking method, use the jacking equipment 13 to push the steel casing 11 into the soil according to the originally designed pipe jacking axis until the concrete pipe 21 that needs to be corrected is completely wrapped, A total station can be used to determine whether the jacking axis of the steel casing 11 coincides with or is lower than the jacking axis of the original concrete pipe 21;

[0046] Step 3: Clean up the earth in the steel casing 11 until the machine head 22 is exposed;

[0047] Step 4: Release the connection between the inside ...

Embodiment 2

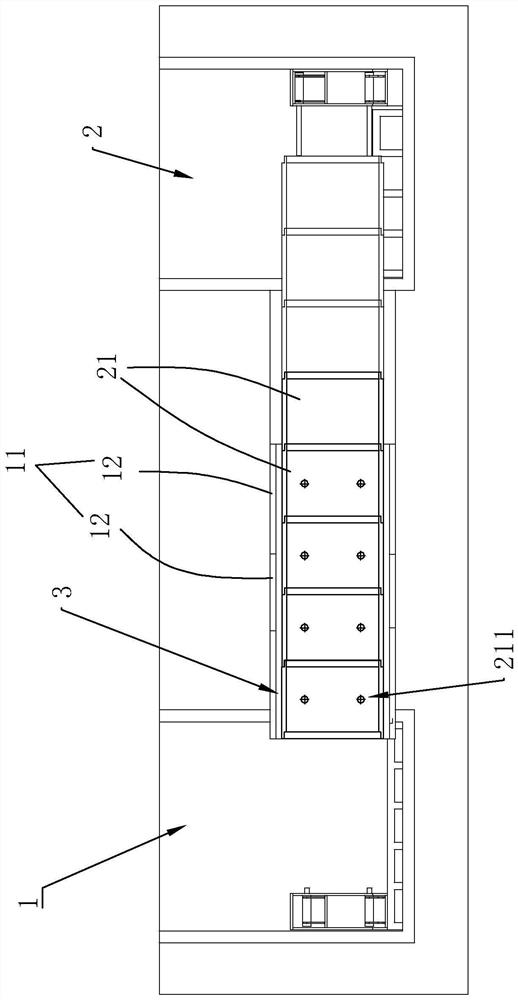

[0057] The difference between this embodiment and Embodiment 1 is that the inner peripheral surface of the steel pipe unit 12 is slidingly connected with a plurality of support blocks 121 around the axis of the steel pipe unit 12, and the plurality of support blocks 121 on any steel pipe unit 12 are along the direction of the steel pipe unit 12. The cells 12 are arranged at equal intervals in the axial direction, and the distance between adjacent support blocks 121 is smaller than the length of the concrete pipe 21 . The inner peripheral surface of the steel pipe body 12 is provided with an arc-shaped chute 122 along the axis of the steel pipe body 12. The chute 122 is a T-shaped groove, and the support block 121 is fixed with a T-shaped block facing the arc surface of the steel pipe body 12. , the T-shaped block engages and slides in the T-shaped groove, so as to realize the sliding connection between the support block 121 and the steel pipe unit 12 .

[0058] The cross secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com