Patents

Literature

60results about How to "Safe and efficient process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

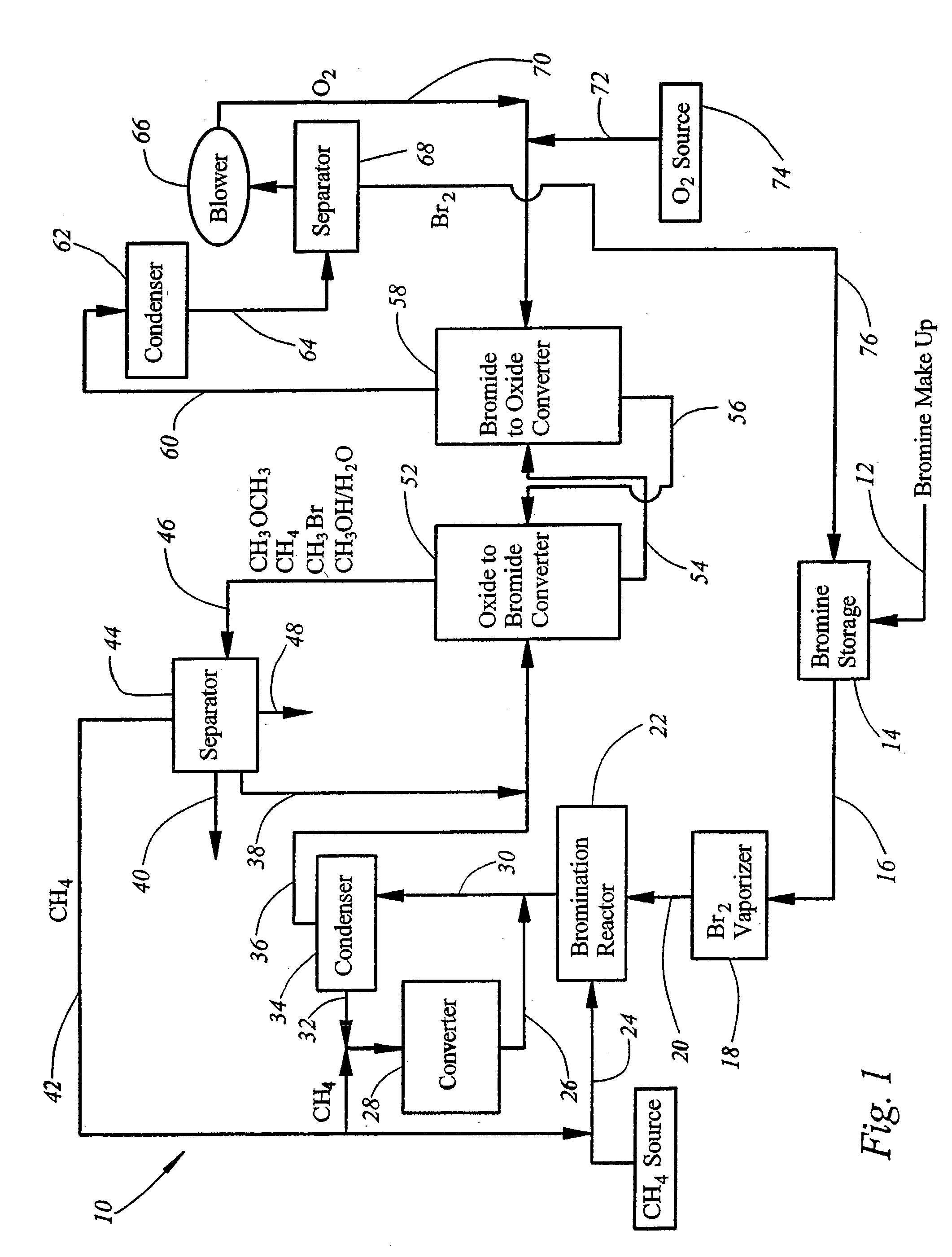

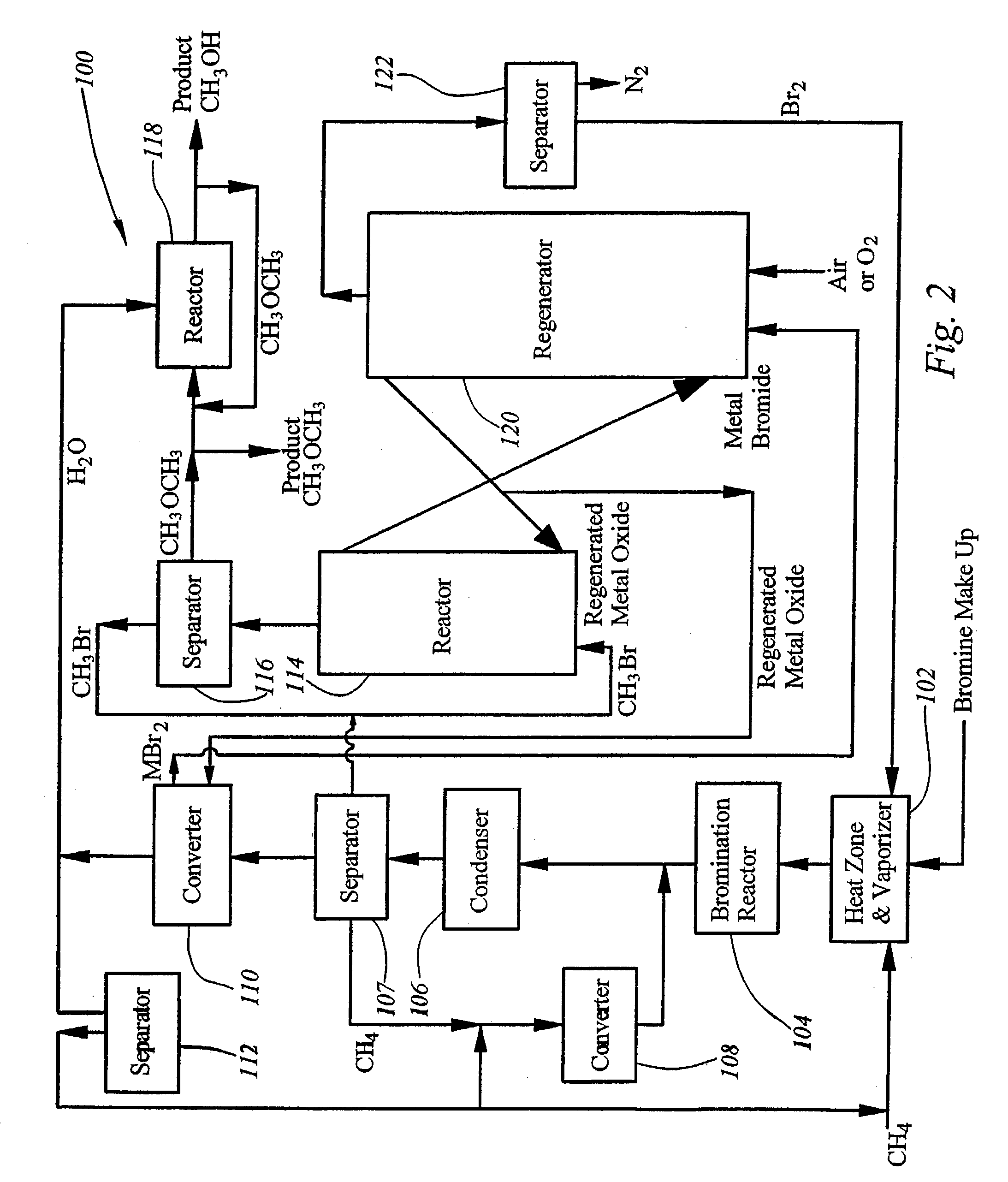

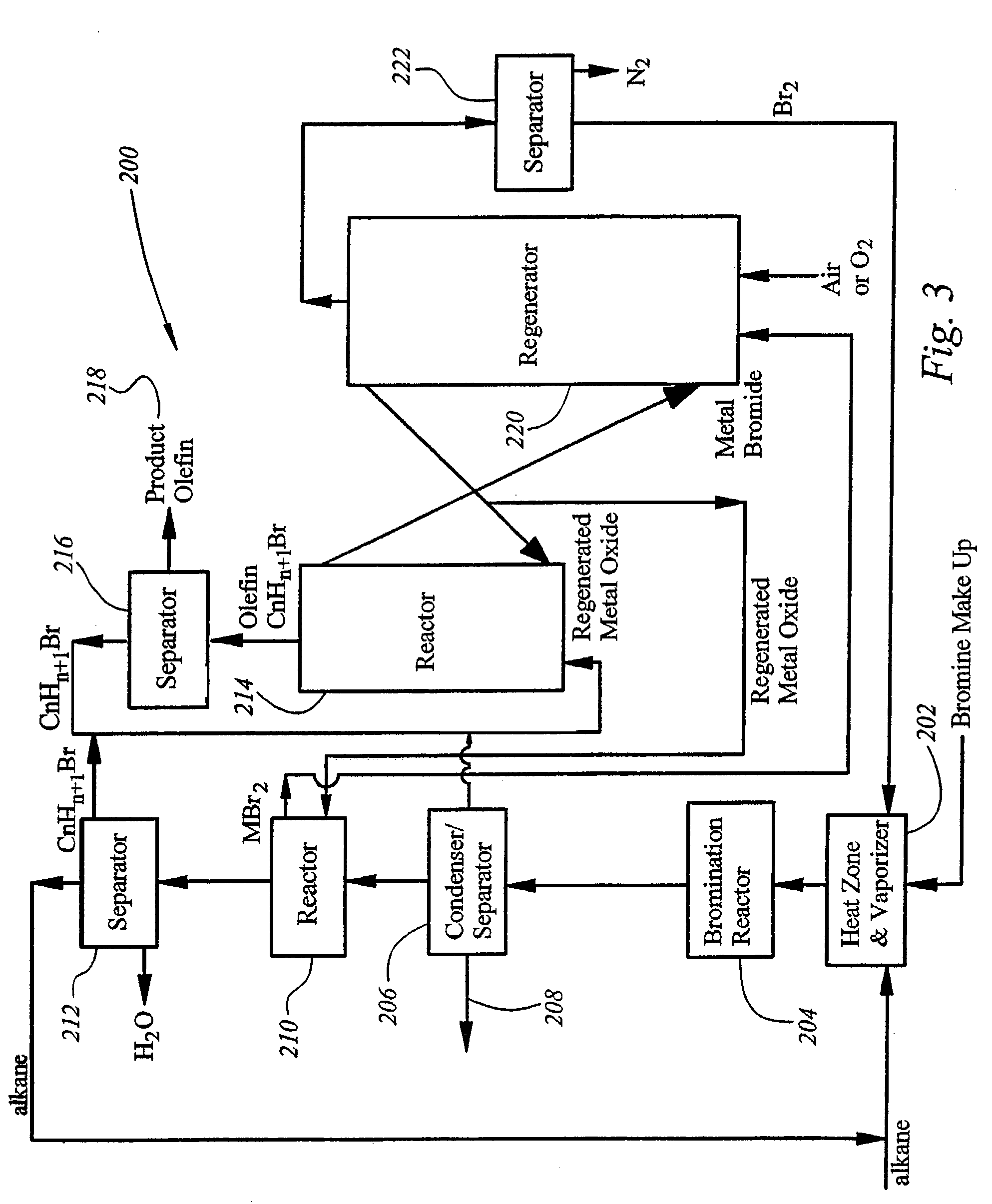

Integrated process for synthesizing alcohols, ethers, aldehydes, and olefins from alkanes

InactiveUS7148390B2Less corrosiveImprove securityOrganic compound preparationChemical industryHydrogen halideAlkane

Alcohols, ethers, aldehydes, and olefins are manufactured from alkanes by mixing an alkane and a halogen selected from the group including chlorine, bromine, and iodine in a reactor to form alkyl halide and hydrogen halide. The alkyl halide only or the alkyl halide and the hydrogen halide are directed into contact with metal oxide to form an alcohol and / or an ether, or an olefin and metal halide. The metal halide is oxidized to form original metal oxide and halogen, both of which are recycled.

Owner:REACTION 35 LLC

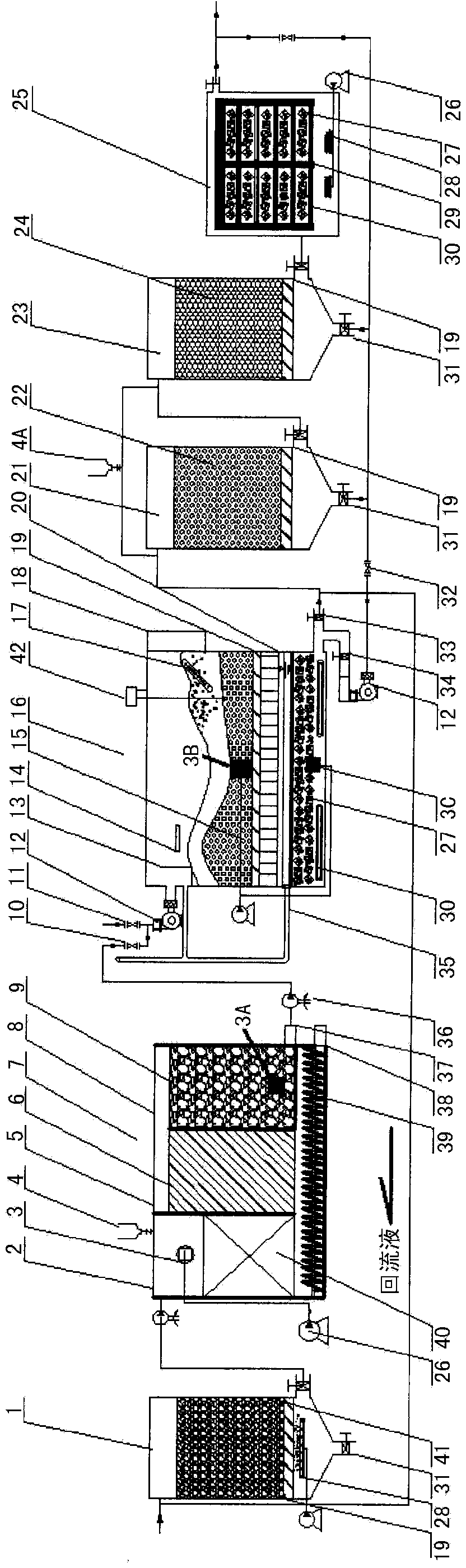

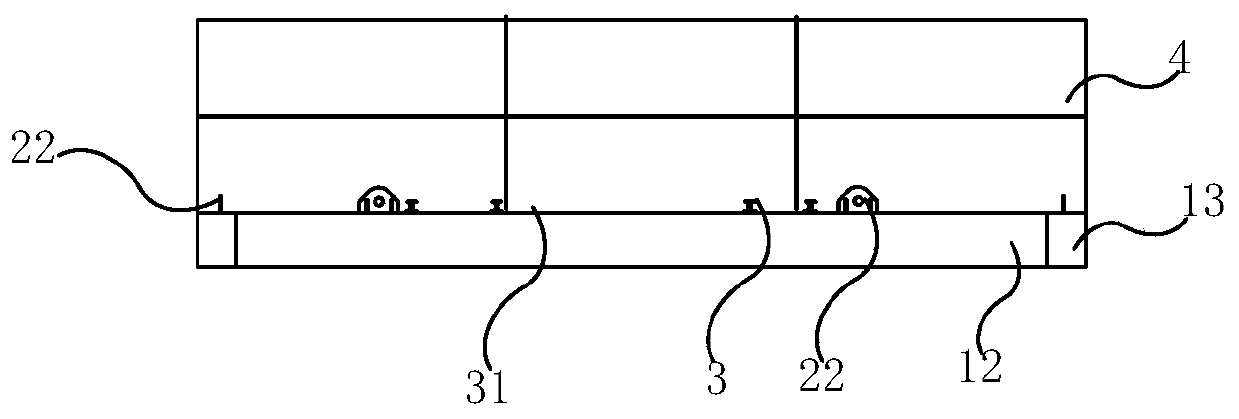

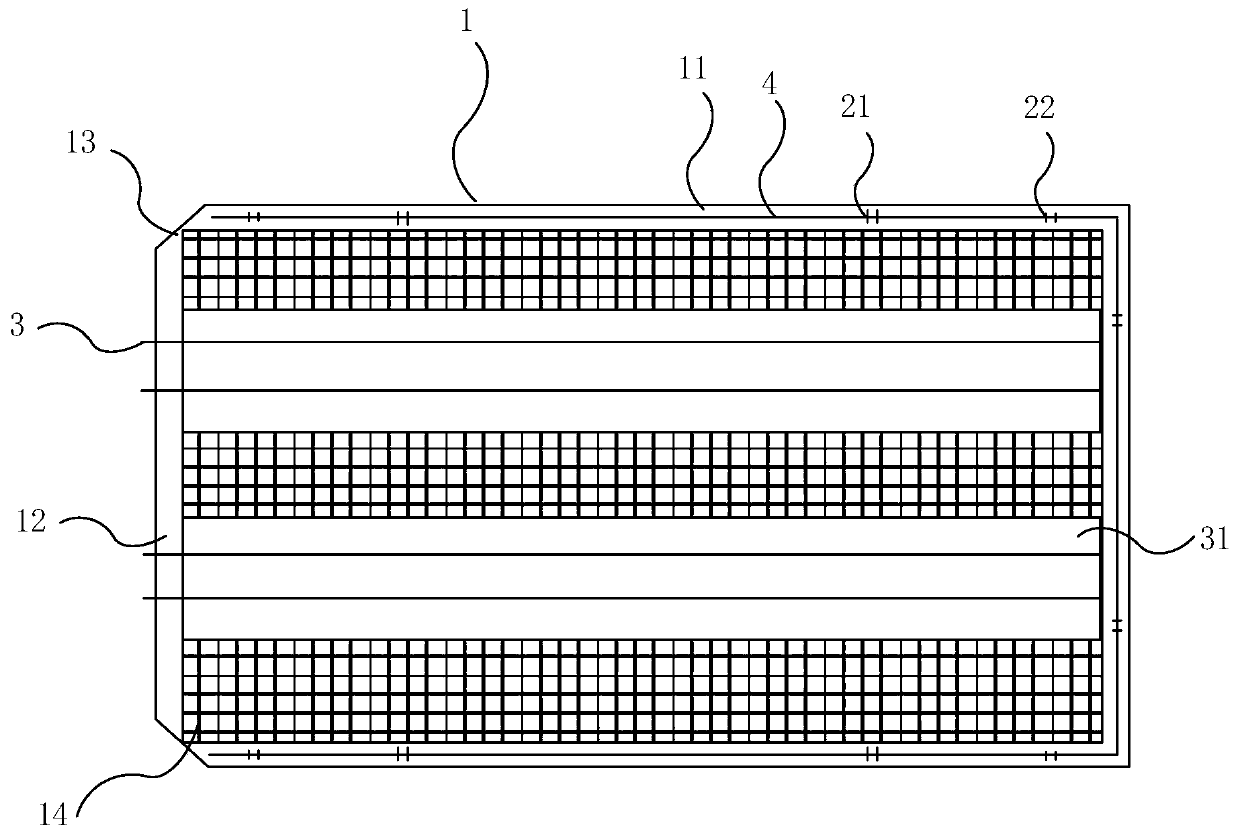

Device for filtering sewage step by step and method for treating sewage by using device

InactiveCN104193081AIncrease contact areaIncrease contact timeMultistage water/sewage treatmentThree levelTurbidity

The invention provides a device for filtering sewage step by step. The device mainly comprises a biofilter, a nano aerated coagulation-micro-vortex flocculation device, a three-level backflushing and screening device, a nitrogen adsorption tank, a phosphorus adsorption tank and a photocatalytic degradation reaction device. The invention also discloses a method for treating sewage by utilizing the device. The device and the method have the beneficial effects that the pollutants difficult to degrade, such as residual polycyclic aromatic hydrocarbon compounds and residual heterocyclic compounds are degraded through deep oxidation and are sterilized, thus reducing the chroma of the effluent by more than 99%; the aromatic fulvic acid substances in the sewage treated by the device are reduced by more than 95%; the sewage turbidity is reduced by 99%; the effluent quality and transparency are high; the effluent quality is improved; The method is efficient and safe and is simple to operate; the treated sewage can be recycled for irrigating, flushing the toilets and washing the ground as recycled water.

Owner:席北斗

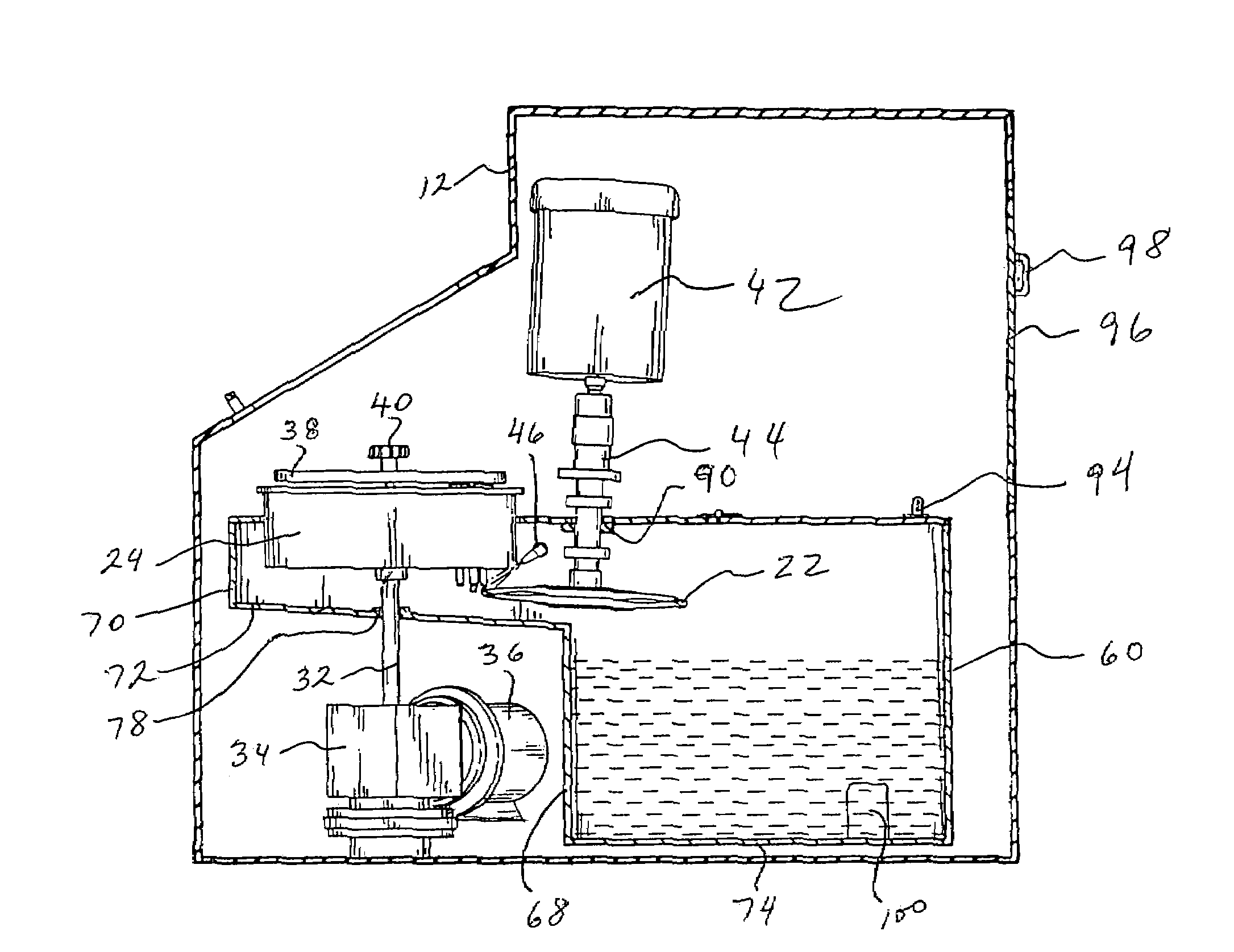

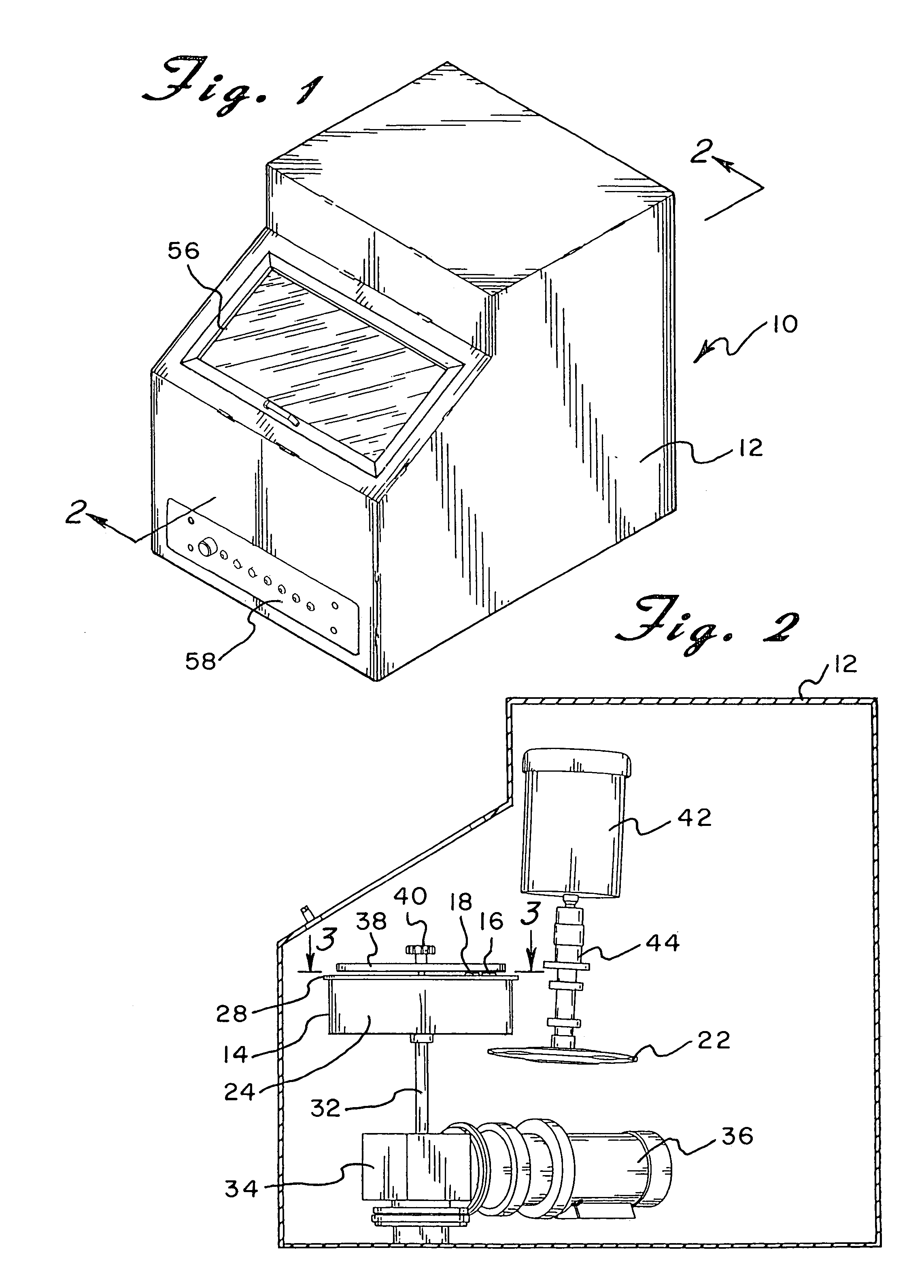

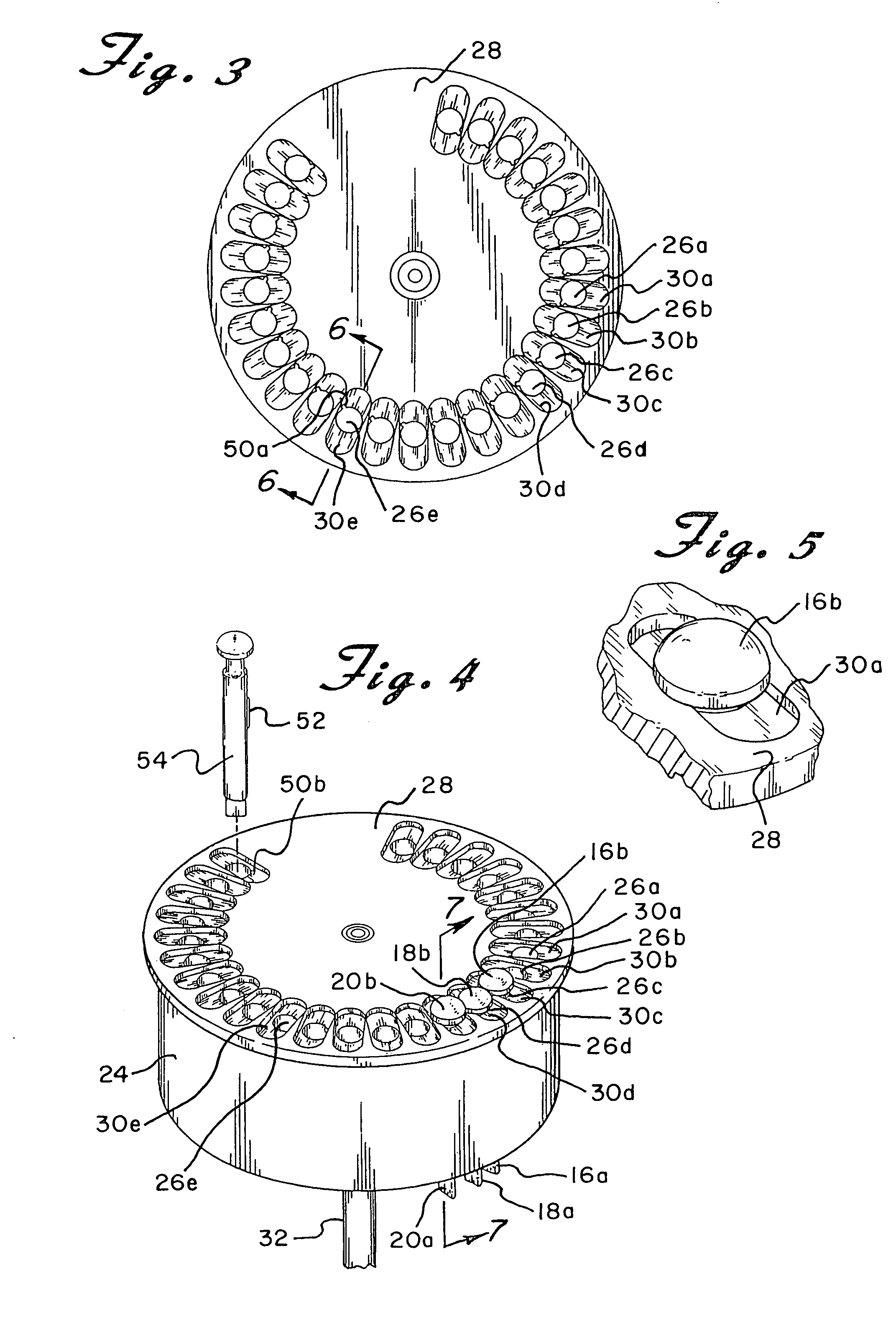

Apparatus for removing the tips of tablet punches

InactiveUS7258052B1Safe and efficient processGang saw millsMetal working apparatusEngineeringVertical axis

Owner:STEVENS PHARMA EQUIP INDS

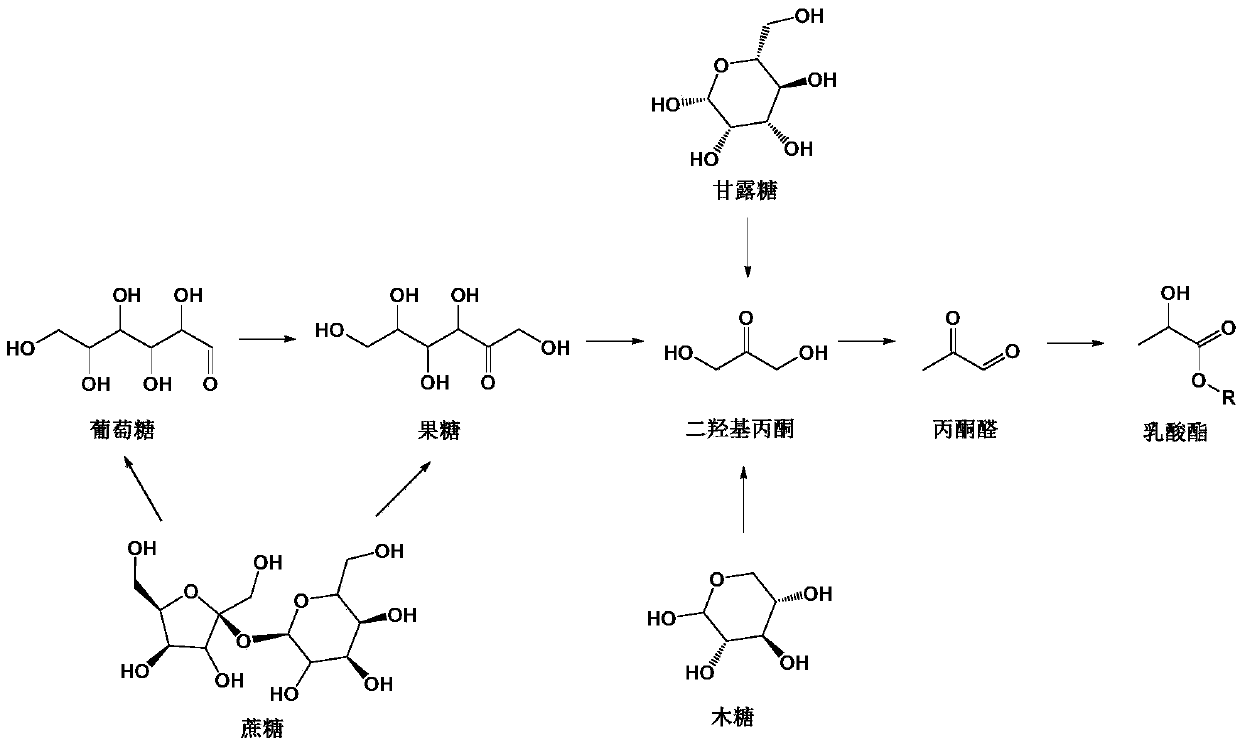

Method for preparing lactate by catalyzing sugar

ActiveCN111253252AImprove reaction efficiencyImprove conversion rateMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention relates to a method for preparing lactate by catalyzing sugar. The method comprises the following steps: contacting sugar and alcohol with a catalyst in a reactor, and reacting to obtaina lactate-containing product, wherein the molar ratio of the sugar to the alcohol is 1:(50-900), the reaction temperature is 150-250 DEG C, the reaction time is 10-50 hours, the catalyst contains a tin-titanium-silicon molecular sieve, and the weight ratio of the sugar to the tin-titanium-silicon molecular sieve based on dry basis weight is 1:(1-6). The method provided by the invention has high sugar conversion rate and high lactate yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

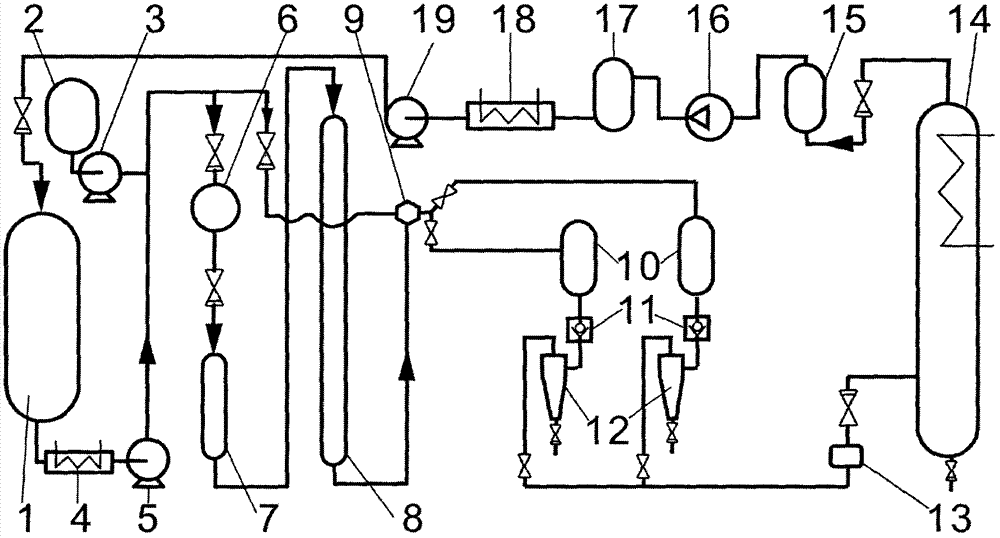

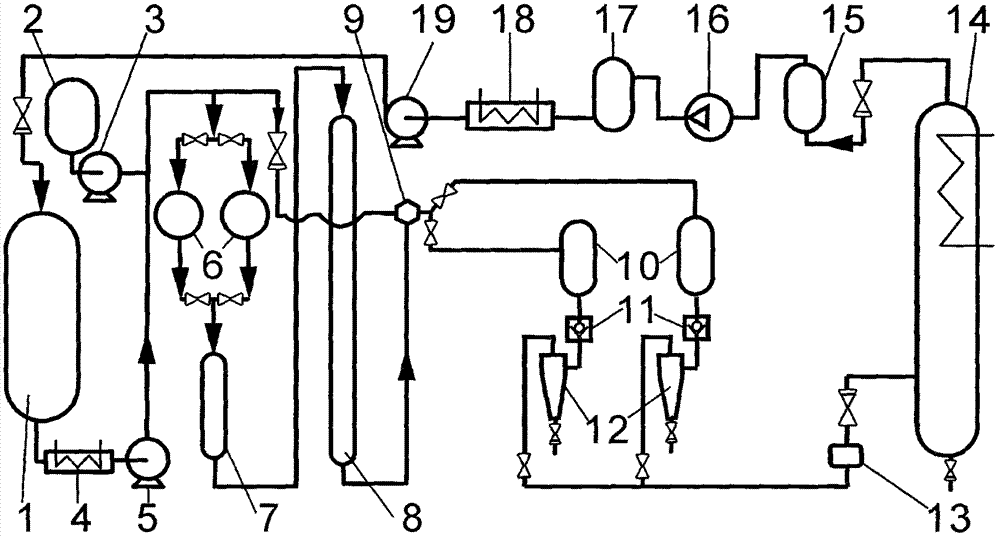

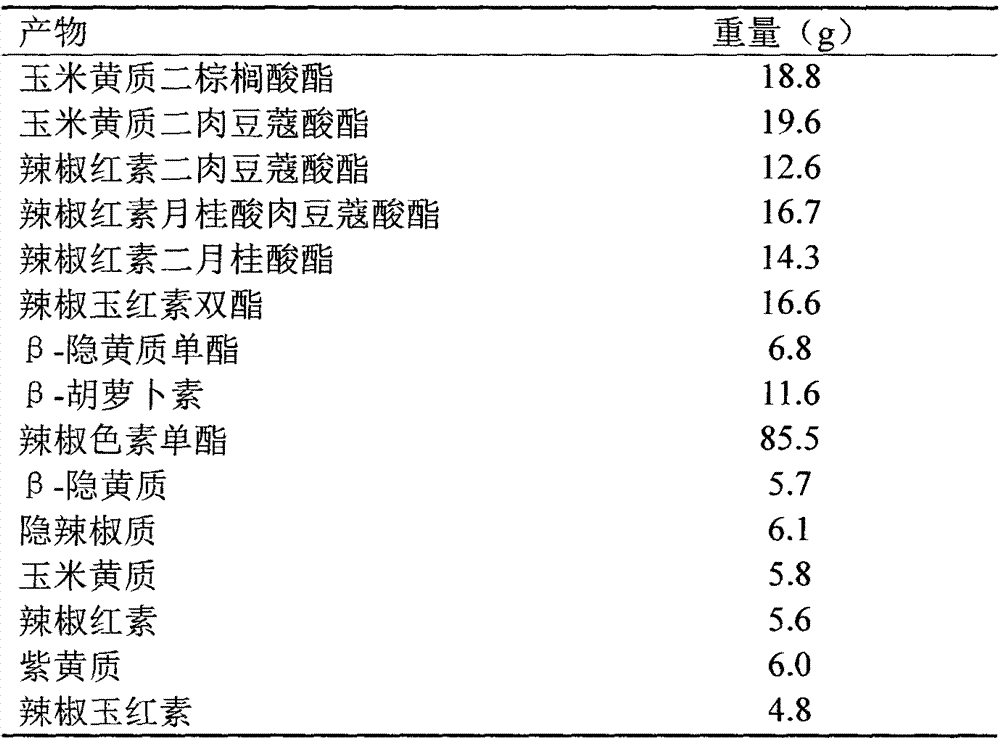

Method and device for preparing highly-pure capsicum pigment capsaicin through supercritical fluid column chromatography

InactiveCN107163618ANo pollution in the processSafe and efficient processSolid sorbent liquid separationCarboxylic acid amide separation/purificationChromatographic separationBeta-cryptoxanthin

The invention relates to a method and a device for preparing a highly-pure capsicum pigment capsaicin through supercritical fluid column chromatography. The method comprises the following steps: mixing and dissolving supercritical carbon dioxide or modified supercritical carbon dioxide and capsicum oleoresin or saponification products thereof in a feeding tank, filtering the obtained solution, carrying out adsorption and desorption separation through a preparative chromatography column filled with solid adsorbent particles, collecting an eluate containing different solutes to corresponding collectors according to the signal of a detector, separating the solute components and carbon dioxide in a separator, carrying out filtering dedusting, condensation liquid removal, adsorption column purification and compression on tail gas to form a liquid, and returning the liquid to a storage tank in order to carry out cycle use. Extremely low solvent residual and even no solvent residual products with a high purity, such as capsanthin, capsorubin, beta-carotene, beta-cryptoxanthin, zeaxanthine, capsanthin ester, capsorubin ester and cryptoxanthin ester, and highly pure products, such as nordihydrocapsaicin, capsaicin and dihydrocapsaicin can be prepared through the method.

Owner:GUANGZHOU LEADER BIO TECH

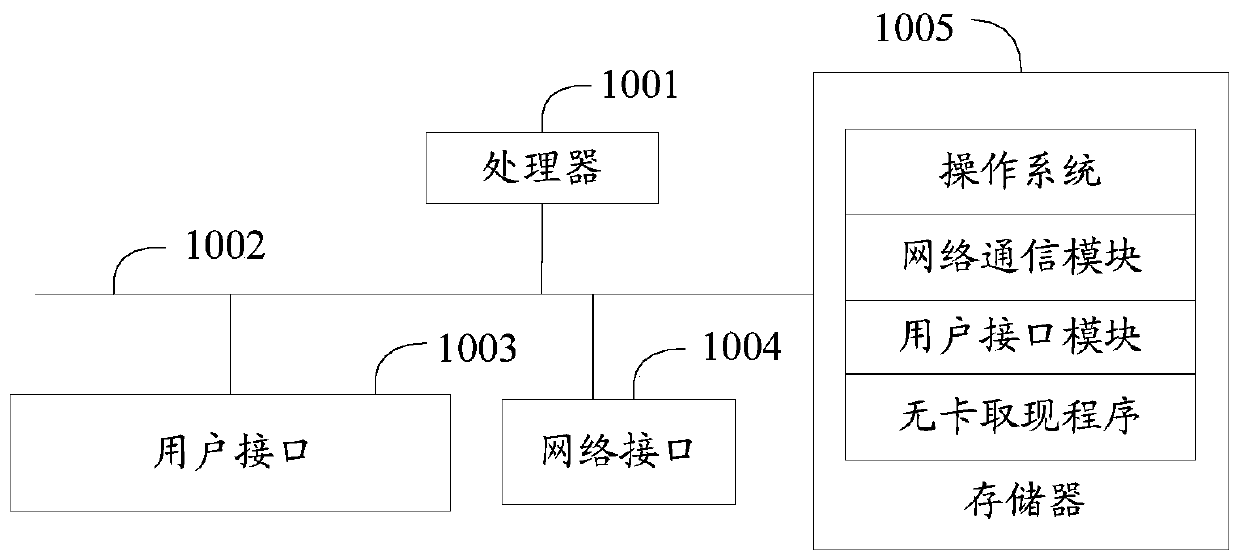

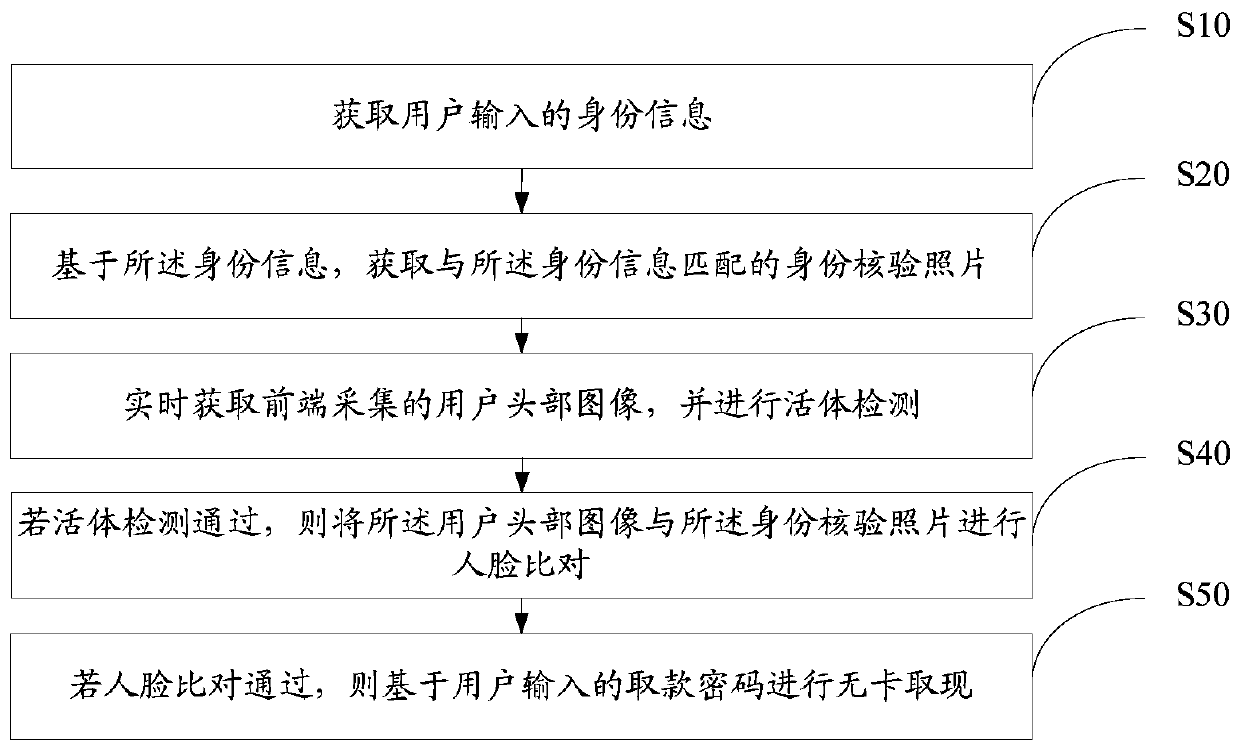

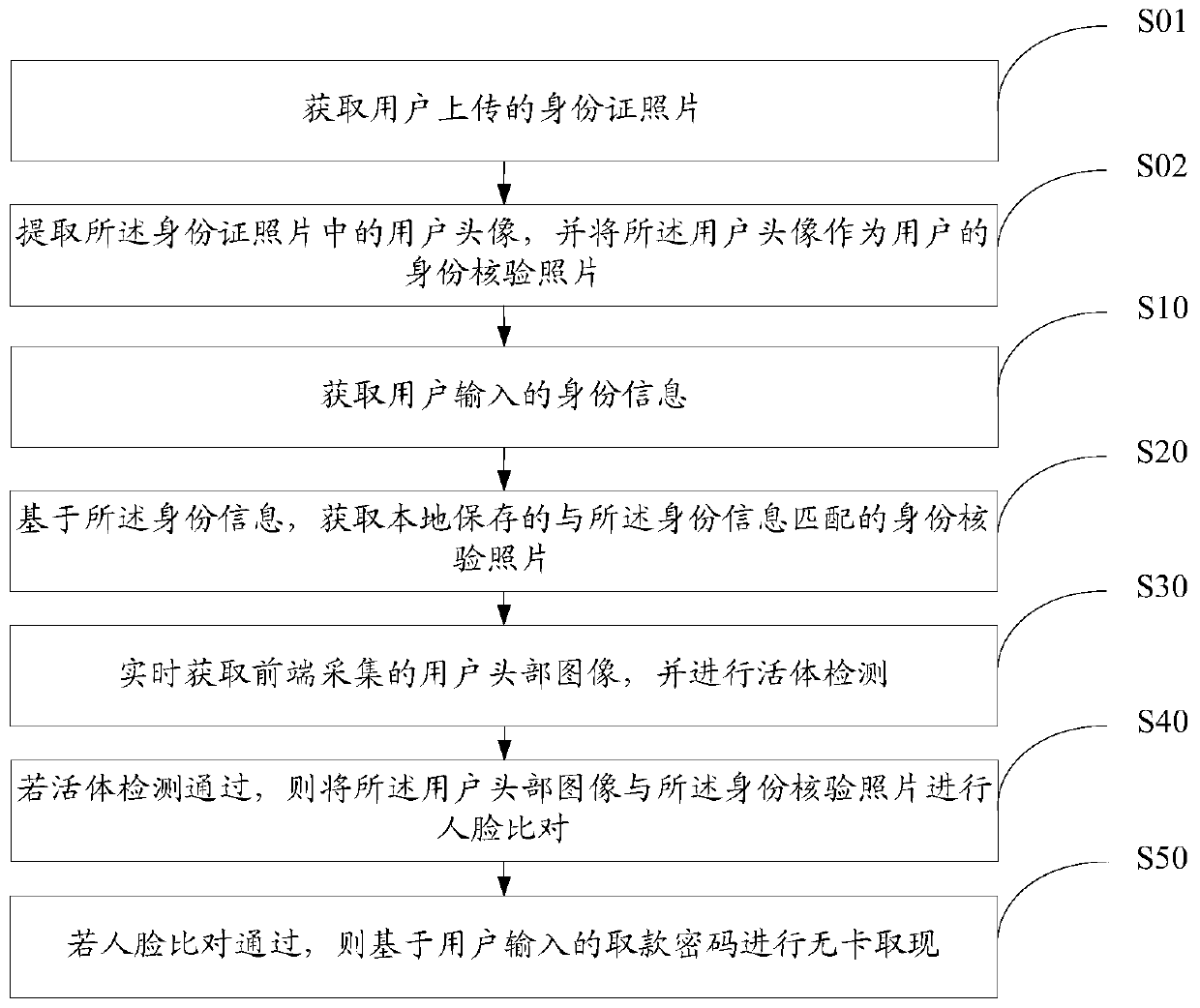

Card-free cash withdrawal method, device and equipment and computer readable storage medium

PendingCN110321792AMeet needsImprove user experienceComplete banking machinesAutomatic teller machinesUser needsUser input

The invention relates to the technical field of artificial intelligence, and discloses a card-free cash withdrawal method, which comprises the following steps of: obtaining identity information inputby a user; based on the identity information, obtaining an identity verification photo matched with the identity information; acquiring a user head image acquired by the front end in real time, and performing living body detection; if the living body detection is passed, performing face comparison on the user head image and the identity verification photo; and if the face comparison is passed, carrying out card-free cash withdrawal based on a withdrawal password input by the user. The invention further discloses a card-free cash withdrawal device and equipment and a computer readable storage medium. According to the invention, on the premise of ensuring the same security level as card-holding cash withdrawal, a quicker and more convenient card-free cash withdrawal mode is provided for a user, the user requirements are met, and the user experience is improved.

Owner:PING AN BANK CO LTD

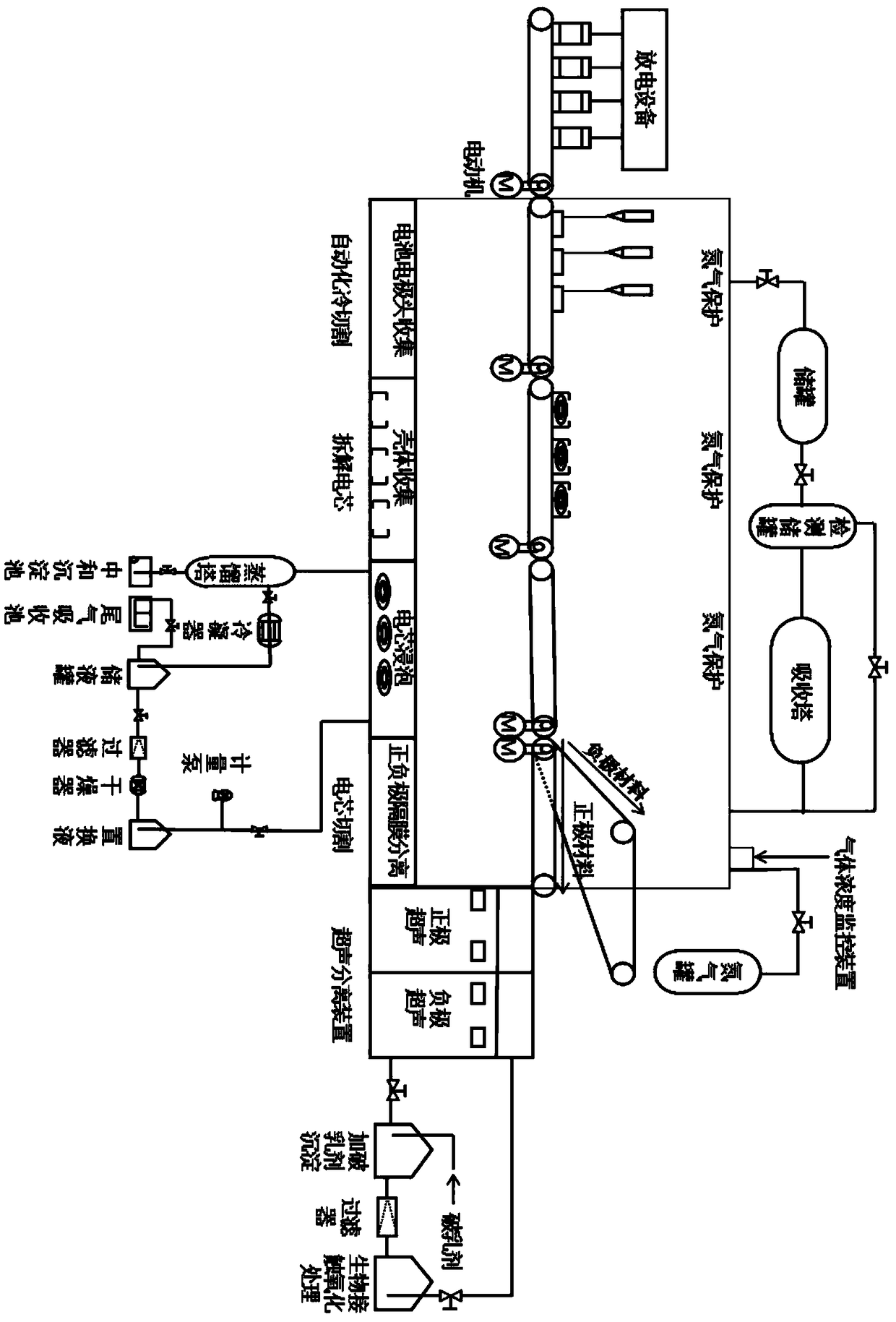

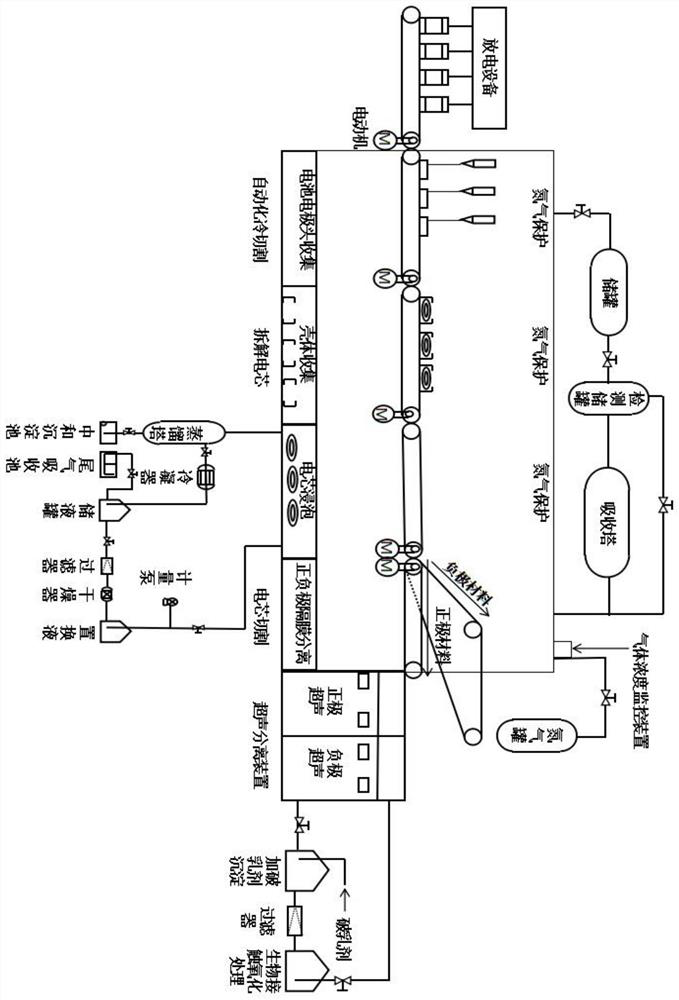

A method for environmentally friendly recycle and reusing waste pow battery

ActiveCN109244586ASolve the safety problem of being volatile and easily decomposed into toxic and harmful gasesHarm reductionWaste accumulators reclaimingBattery recyclingFiltrationHazardous substance

A method for recycling and reusing waste power battery belongs to that field of recycling waste battery. The battery is completely discharged and placed under a sealed and protective gas atmosphere, and the battery pole head, the shell and the battery cell are collected by cold cutting; the obtained cell is immersed and cleaned in the replacement solution. And the positive electrode, the negativeelectrode and the diaphragm are separated by unwinding; The positive and negative electrode pieces are respectively soaked in distilled water and ultrasonicated to obtain positive and negative electrode materials, aluminum foil and copper foil; The electrolyte volatile in the process of cell disassembly is absorbed by absorption tower. Distillation, condensation, filtration and drying are used forrecycling of the replacement liquid used in the cell immersion process, and the harmful substances are recovered through a neutralization sedimentation tank and a tail gas absorption tank. The ultrasonic liquid is recycled after being precipitated by adding demulsifier, filtered and treated by biological contact oxidation. The invention realizes the recovery and regeneration of the waste lithiumion battery, the process is safe, harmless, the automation degree is high, the treatment is efficient and convenient, and the secondary pollution to the environment is not generated.

Owner:BEIJING UNIV OF TECH

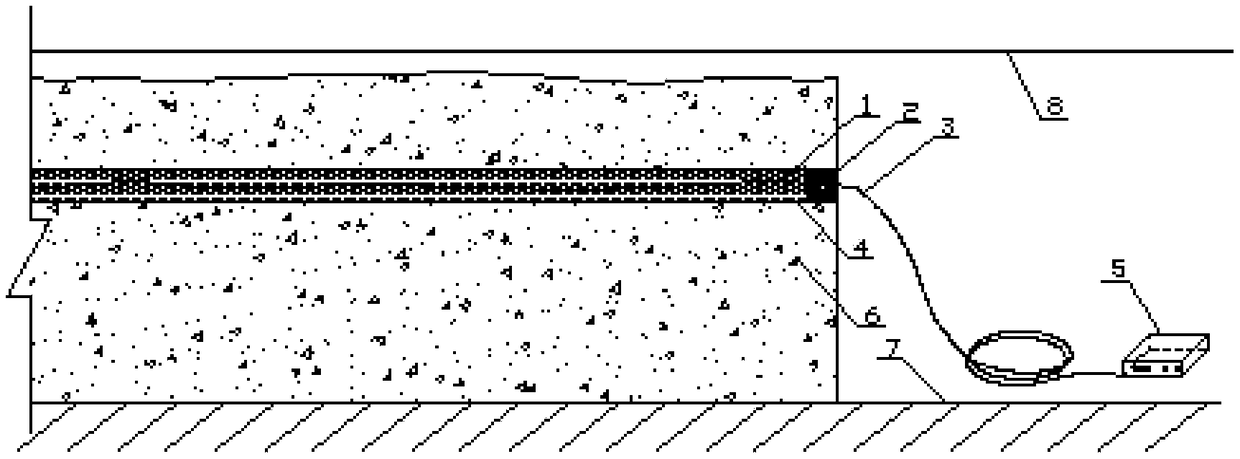

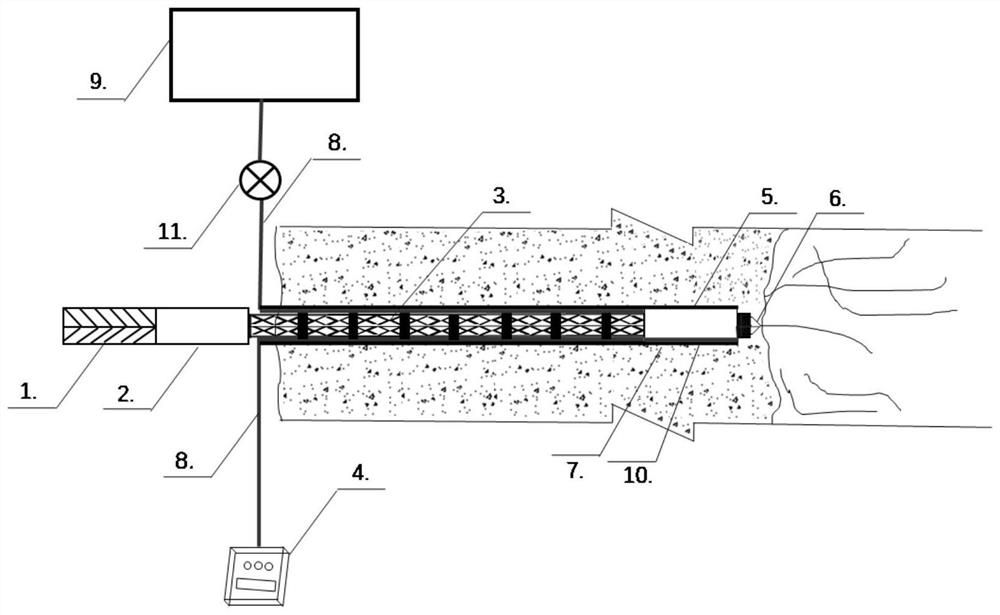

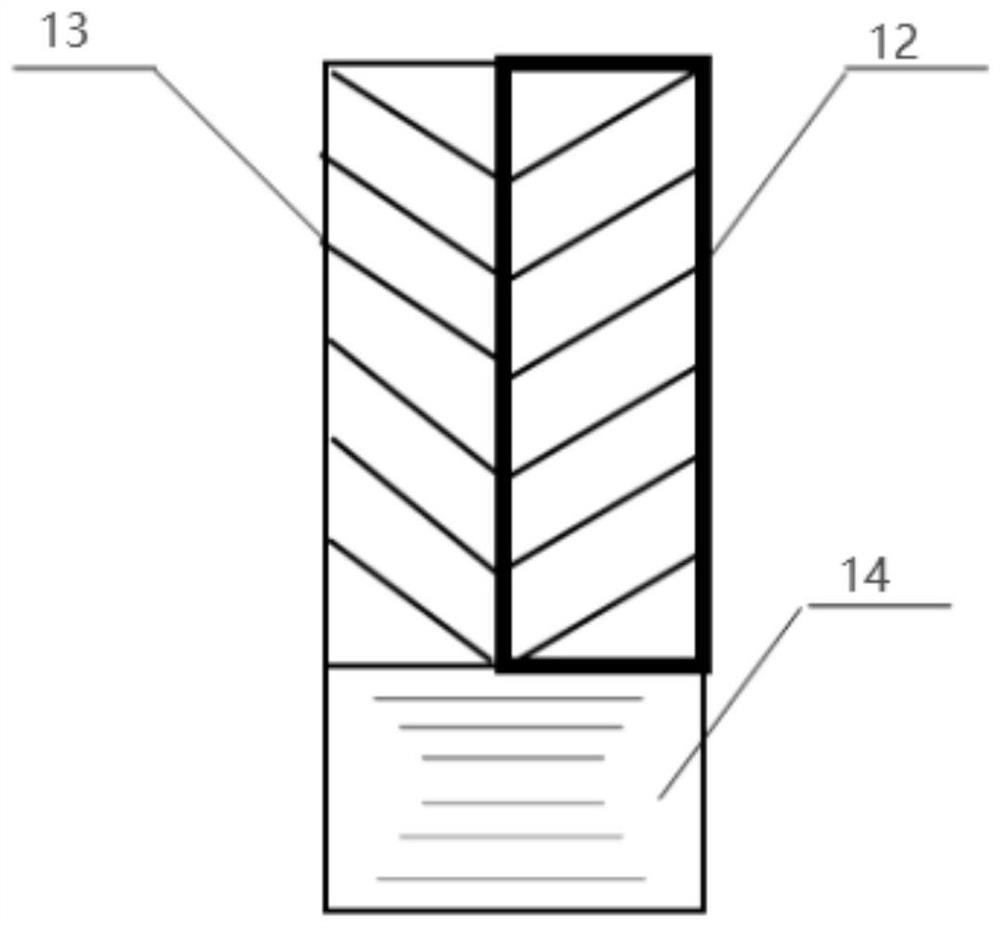

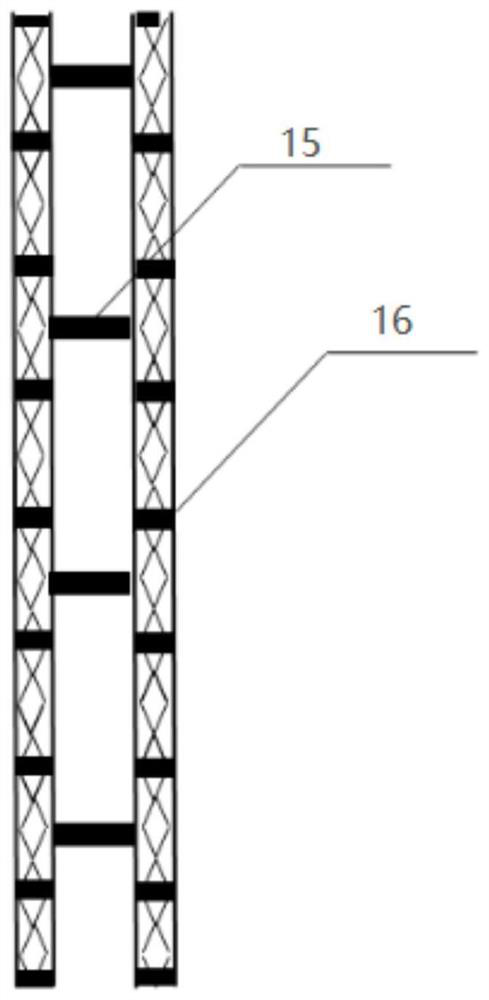

Distributed monitoring system for temperature of underground filling body

InactiveCN109209501ASafe and efficient processAvoid errorsMining devicesMaterial fill-upDrill holeTemperature sense

The invention provides a distributed monitoring system for the temperature of an underground filling body, and belongs to the technical field of paste filling and mining in mines. The distributed monitoring system comprises a temperature sensing optical fiber, a data collection system, an aluminum casing, heat conduction silicone grease, a sealant and the like, wherein the aluminum casing is located in a filling body drill hole; the temperature sensing optical fiber is put into the aluminum casing according to a requirement of the measurement length; the data collection system is located outside the filling body and connected with the temperature sensing optical fiber; the heat conduction silicone grease is located in the aluminum casing and wraps the temperature sensing optical fiber; andthe sealant is located at the outlet of the aluminum casing and mainly used for preventing heat dissipation at the junction. The distributed monitoring system can accurately monitor the temperature of the filling body at different positions and different hydration time at the same time, and can obtain real-time, online and continuous monitoring data, thereby providing an accurate basis for analyzing the paste performance.

Owner:UNIV OF SCI & TECH BEIJING

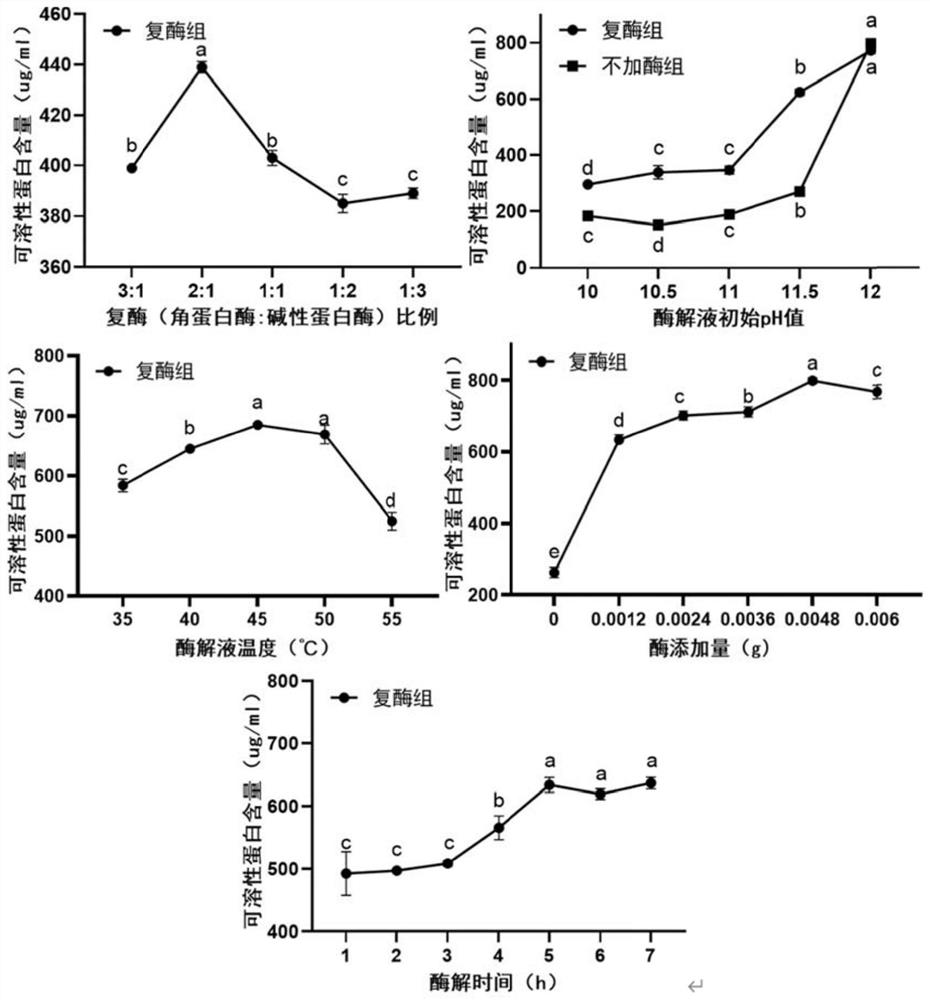

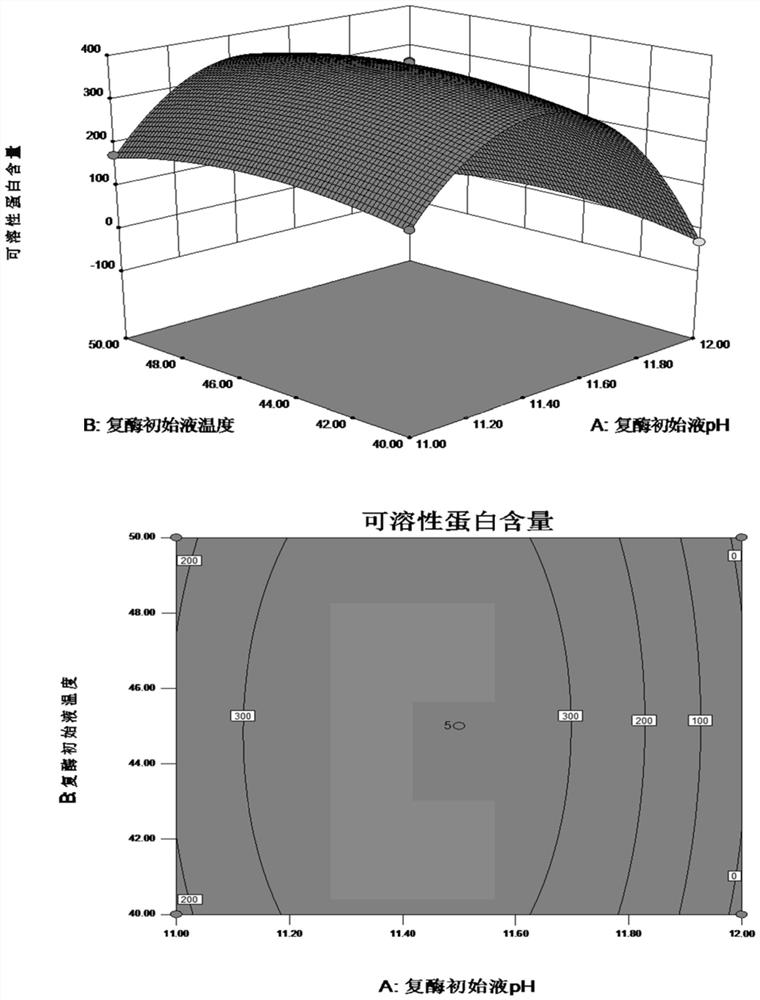

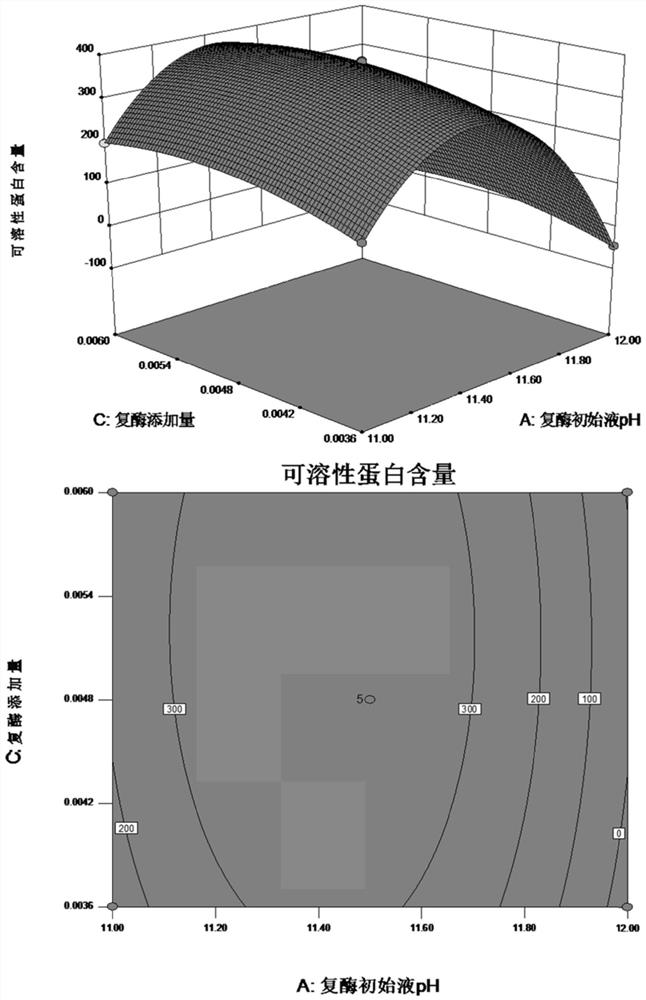

Preparation method of feather peptide powder

InactiveCN111802508AIncrease profitPromote safe productionAccessory food factorsAnimal proteins working-upBiotechnologyAlkaline proteinase

The invention relates to the technical field of resource utilization of poultry slaughtering waste, and particularly discloses a preparation method of feather peptide powder. The method takes poultryfeathers as a raw material, and is characterized by comprising the following steps of crushing the feathers, and then putting the crushed feathers into a container; injecting water, adding 50-400 U ofkeratinase and 1,000,000-3,600,000 U of alkaline protease into each 1g of feather, adjusting the pH to be 10-11.5, reacting at 40-50 DEG C for 4h-8h, and drying filtrate to obtain a peptide powder product. The process disclosed by the invention is simple to operate, safe and efficient, and has great significance for recycling slaughtering wastes such as feathers. The content of soluble protein inthe filtrate of the product is higher than 680 ug / ml, the peptide content in peptide powder is higher than 95%, the relative molecular mass of peptide is below 2000 Dalton, and the product has higherpurity, can be processed into an animal protein feed raw material, has wider application range and is suitable for wide popularization and application.

Owner:ZHEJIANG UNIV +1

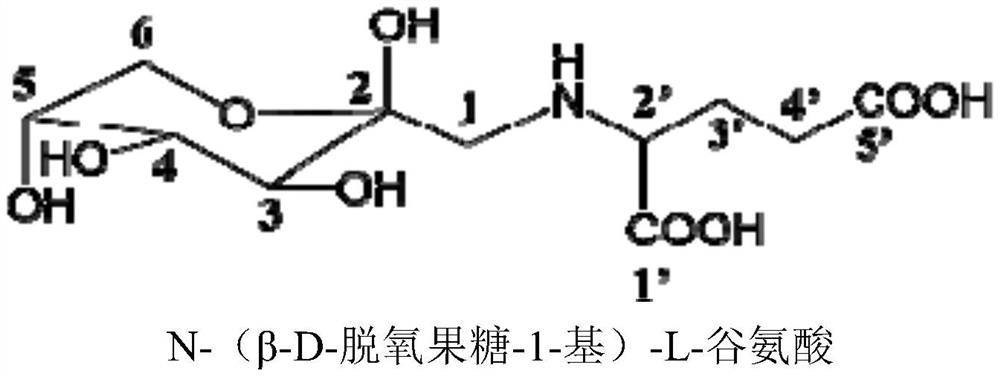

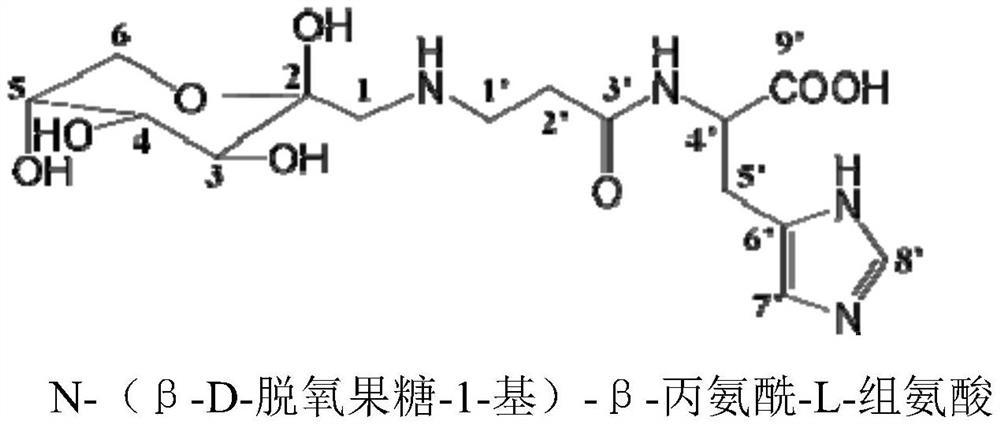

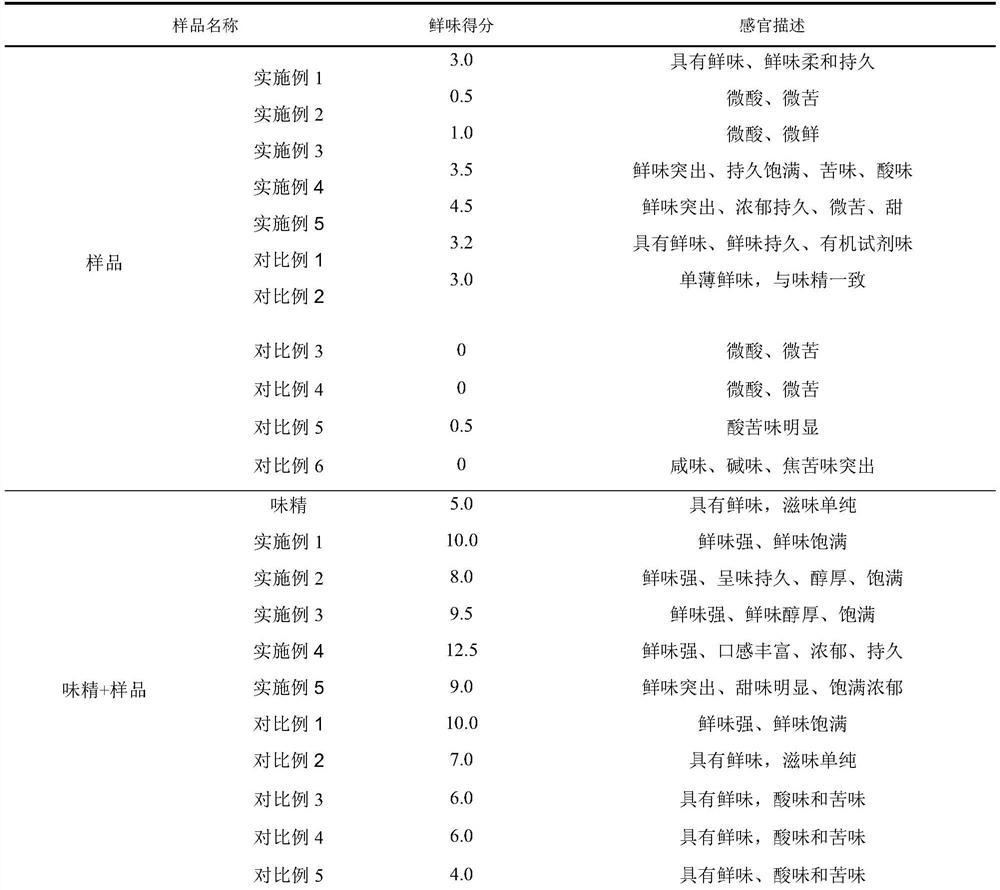

Umami enhancer as well as preparation method and application thereof

PendingCN113785963AImprove flavor profileCompensate or intensify flavor propertiesSugar food ingredientsFood ingredient as taste affecting agentBiotechnologyMaillard reaction

The invention discloses a umami enhancer as well as preparation method and application thereof. The preparation method comprises the following steps of dissolving polypeptide and / or amino acid and saccharides in water, adjusting the pH value of a solution to 5-10, carrying out freeze drying at -65 to -45 DEG C for 5-24 h, heating an obtained product to carry out a Maillard reaction, and rapidly cooling to terminate the reaction after the reaction is finished, so as to obtain the umami enhancer. The prepared Maillard reaction intermediate product is a novel umami compound, can make up or strengthen flavor characteristics of original flavor substances of a food, and also has prominent flavor characteristics of enhancing the umami and fullness of the food. According to the method, the product yield is higher, and the obtained product is mainly in the most stable isomer form of the Maillard reaction intermediate product and is high in purity and relatively high in stability.

Owner:SOUTH CHINA UNIV OF TECH +1

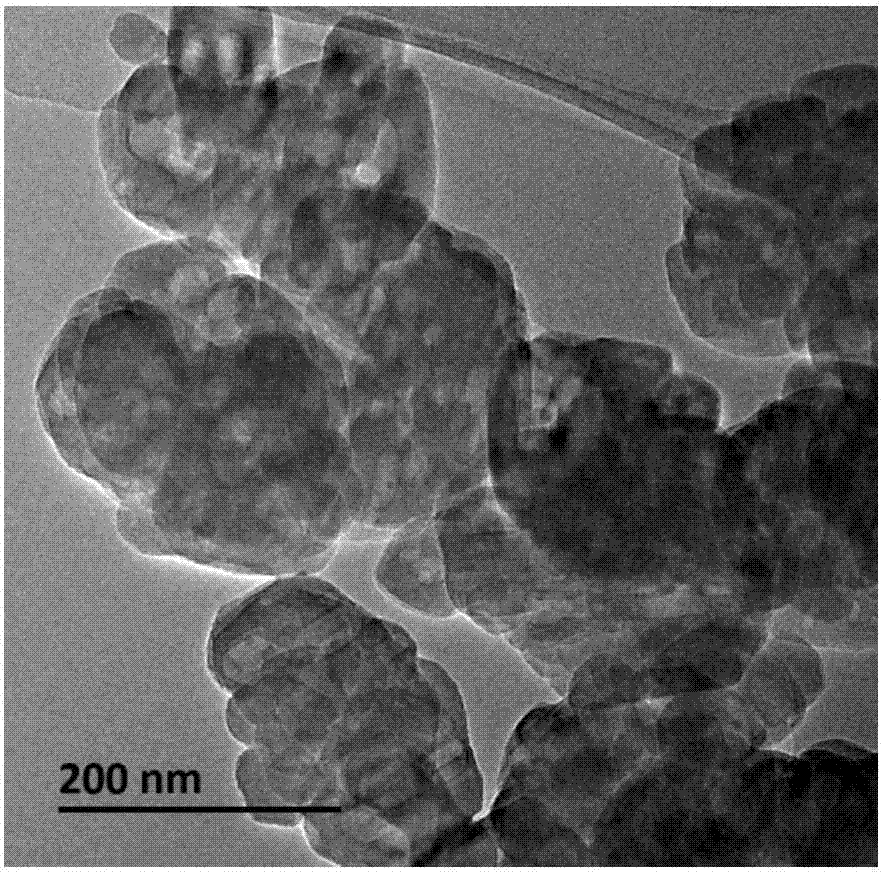

Method for synthesizing MOF derivative semiconductor heterojunction material by solvothermal method

ActiveCN111250074AStable structureImprove photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionPtru catalyst

The invention discloses a method for synthesizing an MOF derivative semiconductor heterojunction material by a solvothermal method, which belongs to the field of catalyst materials. The method specifically comprises the following steps: carrying out hydrothermal crystallization on a mixed reaction system of a soluble ligand organic matter dissolved in an organic solvent and tetra-n-butyl titanate;and washing and drying the obtained product, carrying out continuous two-step calcination in air, dissolving the calcined product and a metal compound in an alkaline solution containing an alcohol solvent, carrying out hydrothermal crystallization for a period of time, washing for multiple times, and finally drying the solid to obtain the target product. The MOF derivative semiconductor heterojunction material product obtained by the method is high in chemical stability and excellent in photocatalytic performance, and the preparation method has the characteristics of simple process flow, lowcost and high product yield.

Owner:UNIV OF SCI & TECH BEIJING

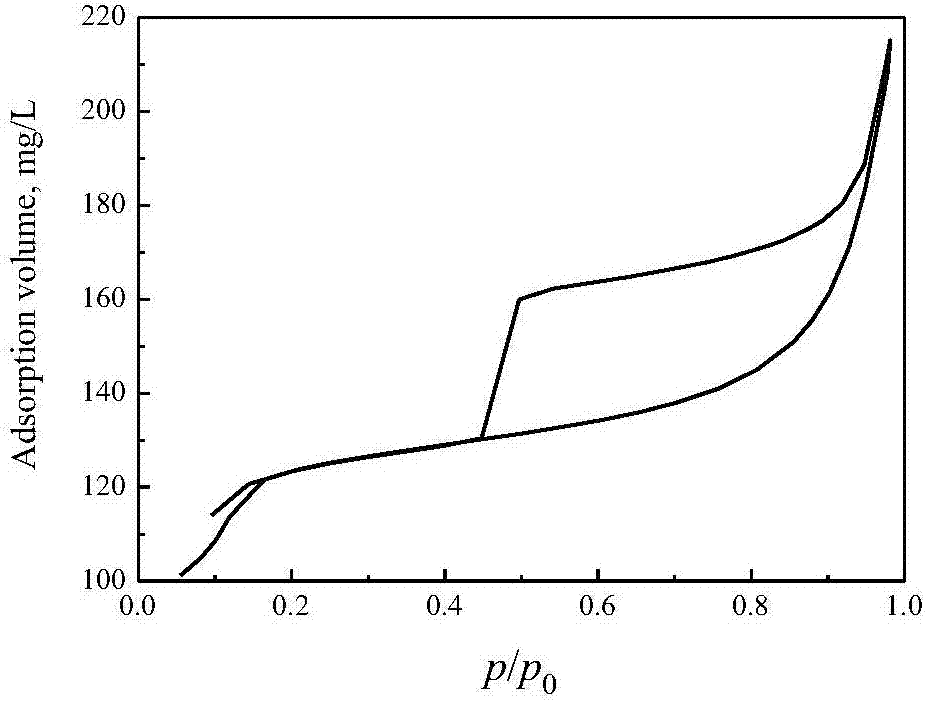

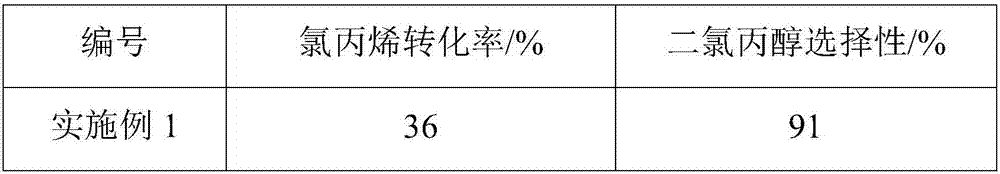

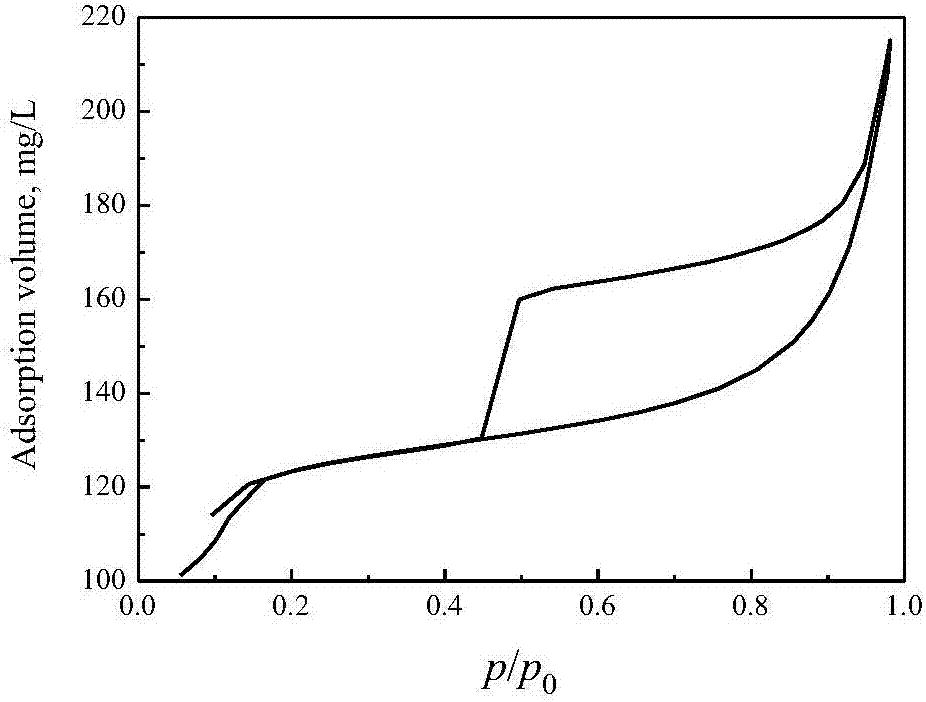

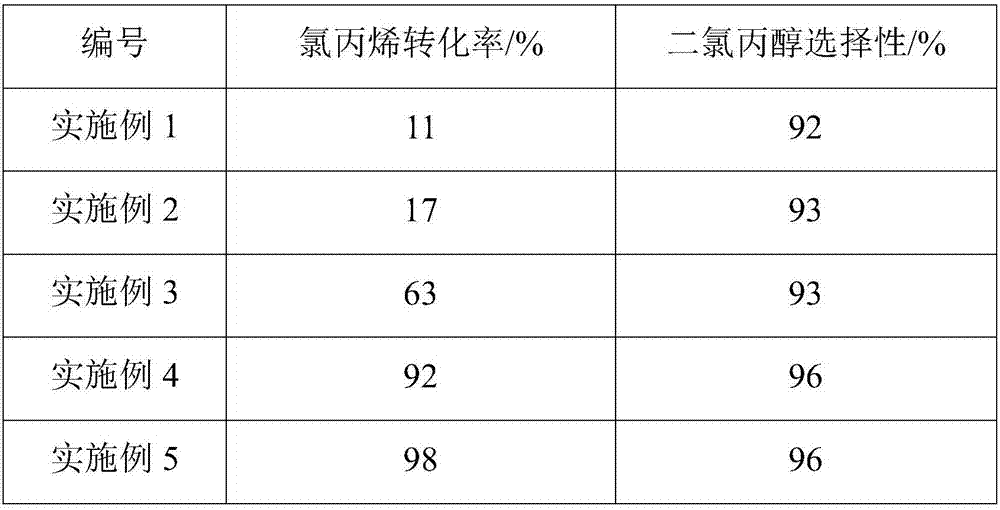

Method for preparing dichloropropanol

ActiveCN107954834AHigh selectivityImprove conversion rateMolecular sieve catalystsPreparation by OH and halogen introductionMolecular sieveHydrogen chloride

The invention discloses a method for preparing dichloropropanol. The method comprises the steps of performing a contact reaction on allyl chloride, hydrogen chloride and an oxidant in the presence ofa catalyst, wherein the catalyst is a titanium silicate molecular sieve catalyst. The method has the characteristics of no use of toxic chlorine, simple operation process, mild reaction conditions, high raw material conversion rate, high selectivity of dichloropropanol, and easy separation of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

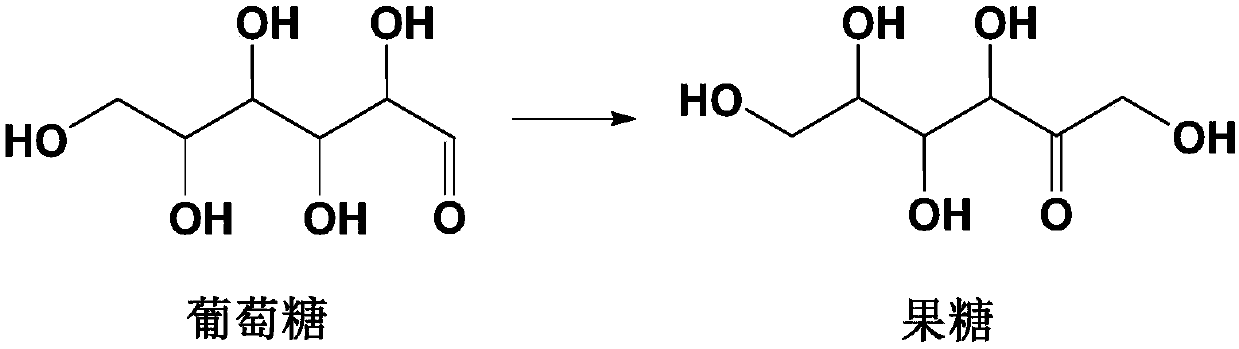

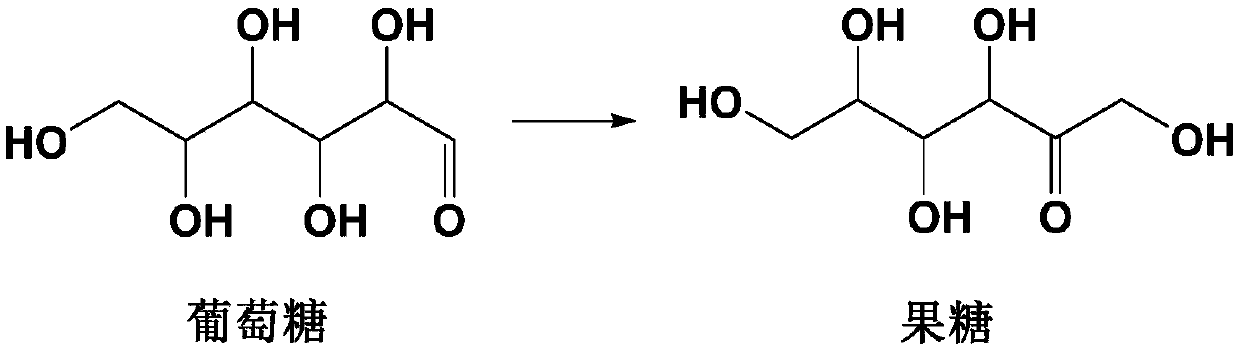

Method for preparing fructose

ActiveCN111253449AImprove conversion rateHigh yieldSugar derivativesChemical recyclingFructoseMolecular sieve

The invention relates to a method for preparing fructose. The method comprises the following steps: allowing glucose to contact with a catalyst in a reactor in the presence of alcohol, and carrying out a reaction so as to obtain a fructose-containing product, wherein the molar ratio of the glucose to the alcohol is 1: (50-600); the reaction temperature is 30 DEG C or above and is lower than 100 DEG C; the reaction time is 1-10 hours; the catalyst contains a mixture of a titanium silicalite molecular sieve and a tin silicalite molecular sieve; and the weight ratio of the glucose to the mixtureof the titanium silicalite molecular sieve and the tin silicalite molecular sieve in terms of a dry basis weight is 1: (0.1-6). The method provided by the invention has high glucose conversion rate and fructose yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dichloropropanol

ActiveCN107954835AHigh selectivityImprove conversion rateMolecular sieve catalystsPreparation by OH and halogen introductionBiological activationHigh selectivity

The invention discloses a method for preparing dichloropropanol. The method comprises the steps of performing a contact reaction on allyl chloride, hydrogen chloride and an oxidant in the presence ofa catalyst, wherein the catalyst contains a titanium silicate molecular sieve subjected to activation treatment and the activation treatment comprises the step of contacting a titanium silicate molecular sieve with an aqueous solution containing an acid and a selectable peroxide. The method has the characteristics of no use of toxic chlorine, simple operation process, mild reaction conditions, high raw material conversion rate, high selectivity of dichloropropanol, and easy separation of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating and purifying Scutellaria baicalensis polysaccharide extracted from radix scutellariae

The invention discloses a method for separating and purifying Scutellaria baicalensis polysaccharide extracted from radix scutellariae. The method utilizes a water system method. The method comprises extracting functional crude polysaccharide from radix scutellariae, flocculating the crude polysaccharide solution through a chitosan-acetic acid aqueous solution, carrying out centrifugal separation, carrying out concentration, carrying out ethanol precipitation and carrying out freeze-drying so that purification of crude Scutellaria baicalensis polysaccharide is realized. The method is simple and easy, has good operability, has simple production processes and realizes earlier fast impurity removal of crude polysaccharide of Scutellaria baicalensis.

Owner:XIAN BOTANICAL GARDEN SHAANXI PROV

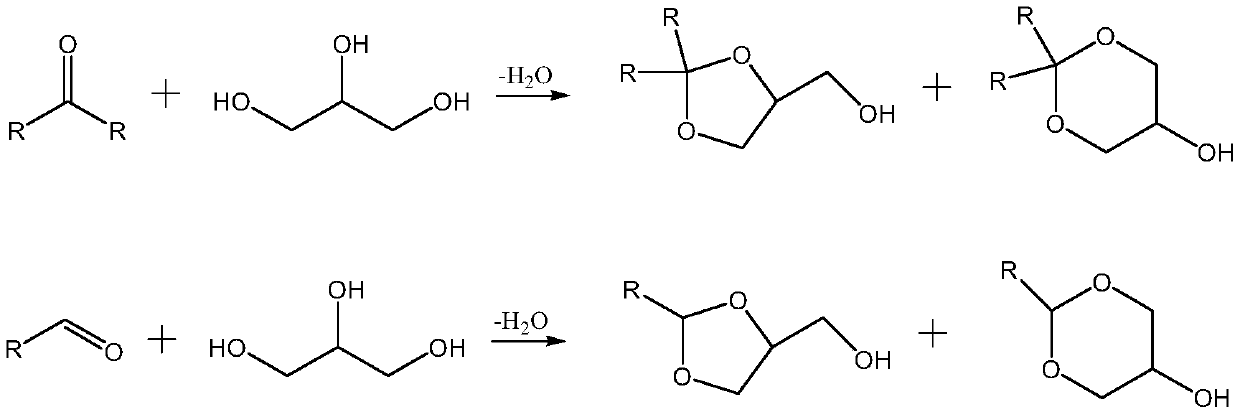

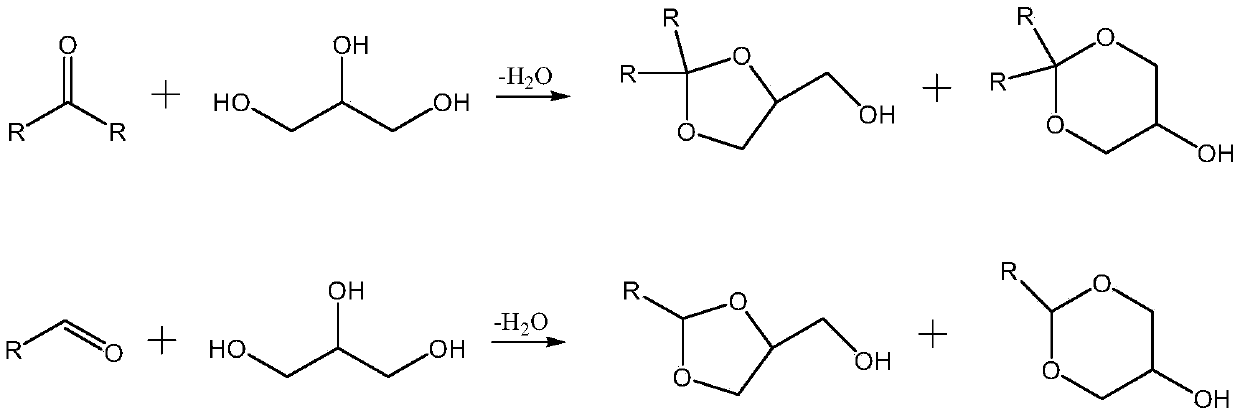

Method for preparing ketal glycerine and/or acetal glycerine

ActiveCN111253359AImprove conversion rateEasy dehydration condensationOrganic chemistryMolecular sieve catalystsMolecular sievePolymer science

The invention relates to a method for preparing ketal glycerine and / or acetal glycerine. The method comprises the following steps: contacting glycerine and a reaction raw material with a catalyst in areactor, and reacting to obtain a product containing ketal glycerine and / or acetal glycerine, wherein the reaction raw material contains aldehyde and / or ketone, the molar ratio of glycerine to aldehyde and / or ketone is 1:(1-10), the reaction temperature is 30-180 DEG C, the reaction time is 1-10 hours, the catalyst contains a tin-titanium-silicon molecular sieve, and the weight ratio of glycerineto the tin-titanium-silicon molecular sieve based on dry basis weight is (1-40):1. The method provided by the invention has high aldehyde / ketone conversion rate and high acetal / ketal glycerine selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

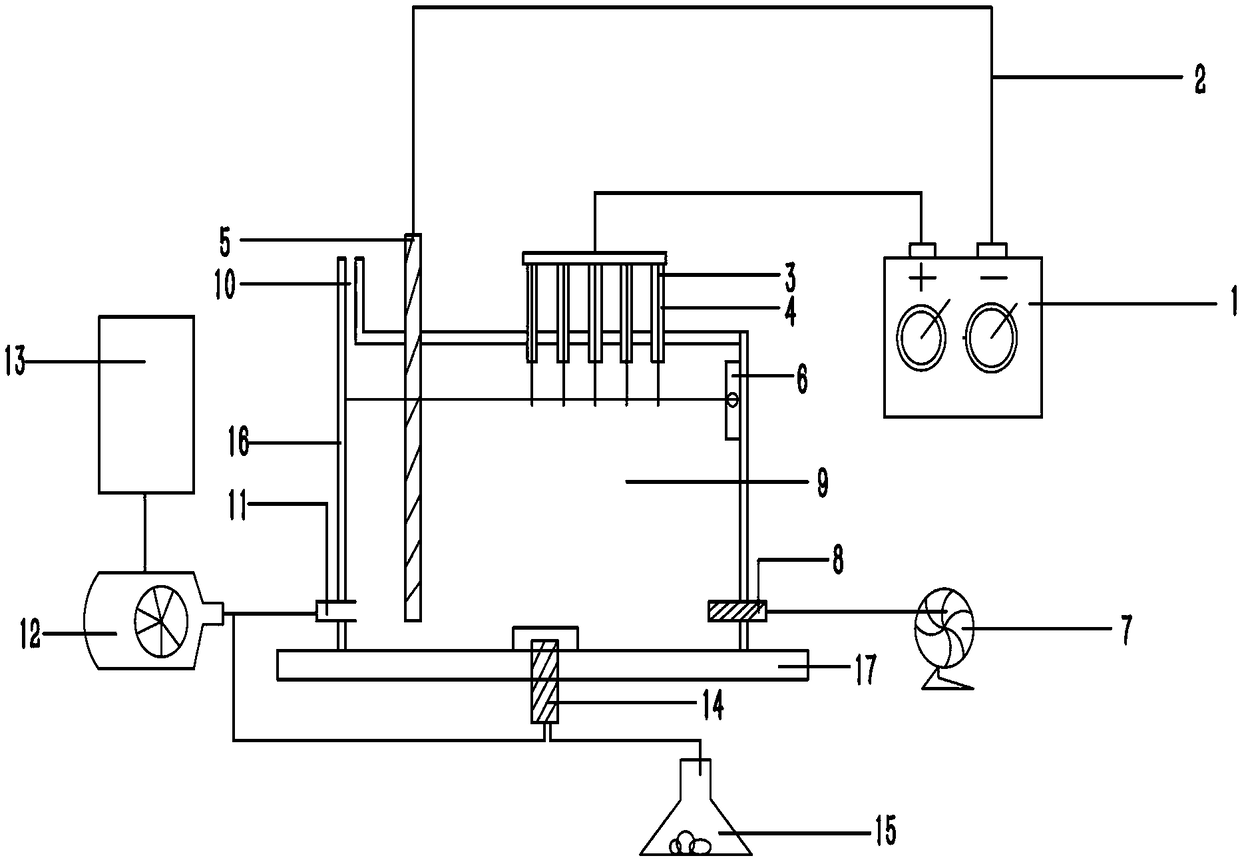

Integrated biogas desulfurizing device and method

The invention discloses an integrated biogas desulfurizing device and method, and belongs to the technical field of biogas desulfurizing. The integrated biogas desulfurizing device comprises a reaction tank, wherein the reaction tank is used for accommodating absorbing liquid; the upper side of the reaction tank is provided with a gas outlet, and the lower side of the reaction tank is provided with a gas collection and distribution port; the gas collection and distribution port is connected with a fan at the exterior of the reaction tank; a high-voltage electrode and a low-voltage end are arranged in the reaction tank; one end, without being immersed under the liquid level, of the high-voltage electrode is connected with a positive electrode of a high-voltage direct current power source control console through a high-voltage conducting wire; one end, without extending under the liquid level, of the low-voltage end is connected with a negative electrode of the high-voltage direct current power source control console. The integrated biogas desulfurizing device has the advantages that a technology route and device combining direct current glow discharge and wet desulfurization are proposed; after reaction, the sulfur element with higher purity can be collected for recycling; the investment cost and running cost are low, and the treatment, regeneration and recycling are integratedtogether.

Owner:XI AN JIAOTONG UNIV

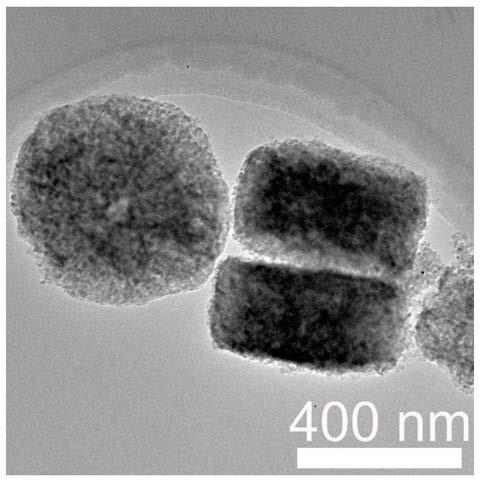

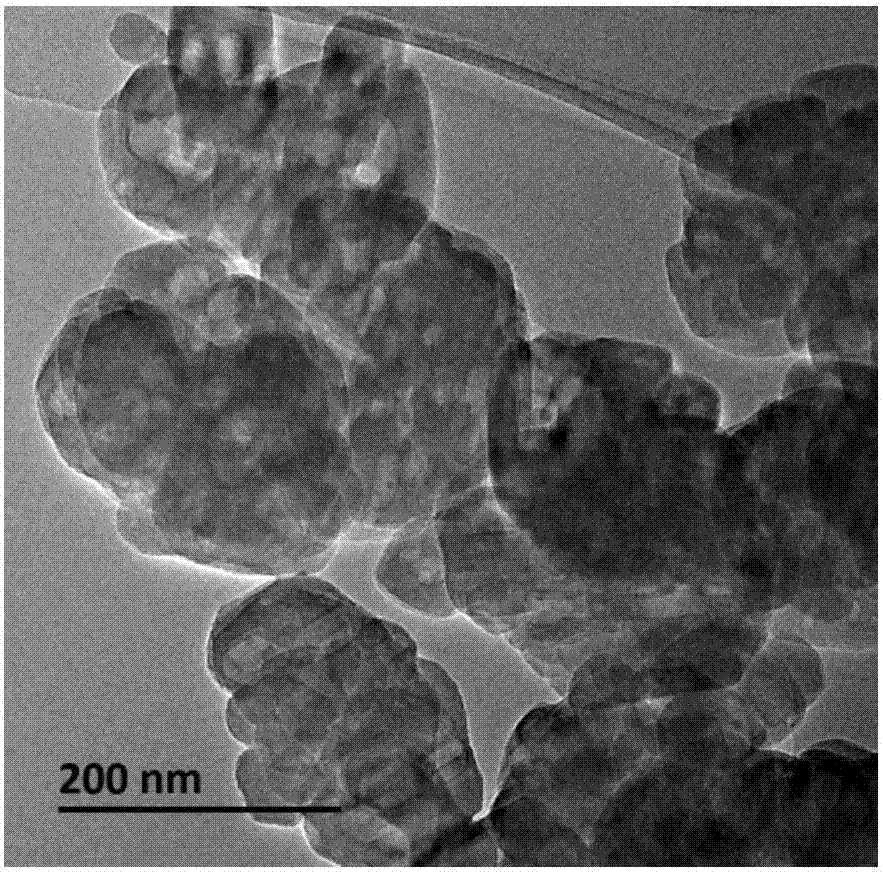

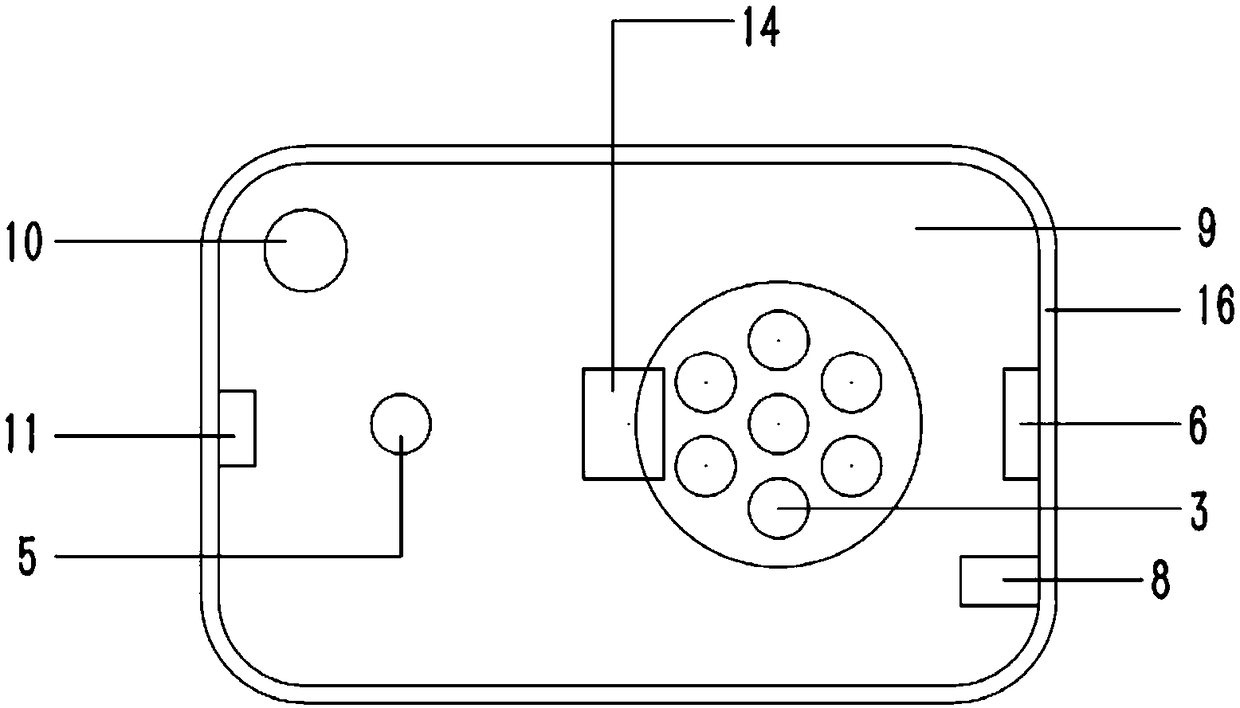

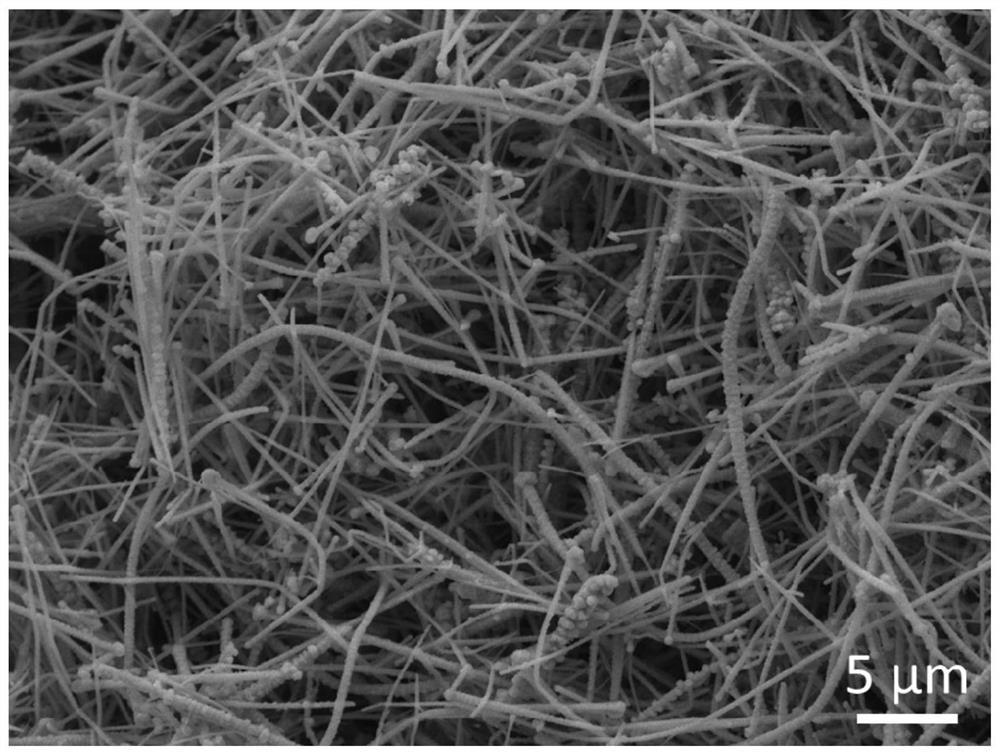

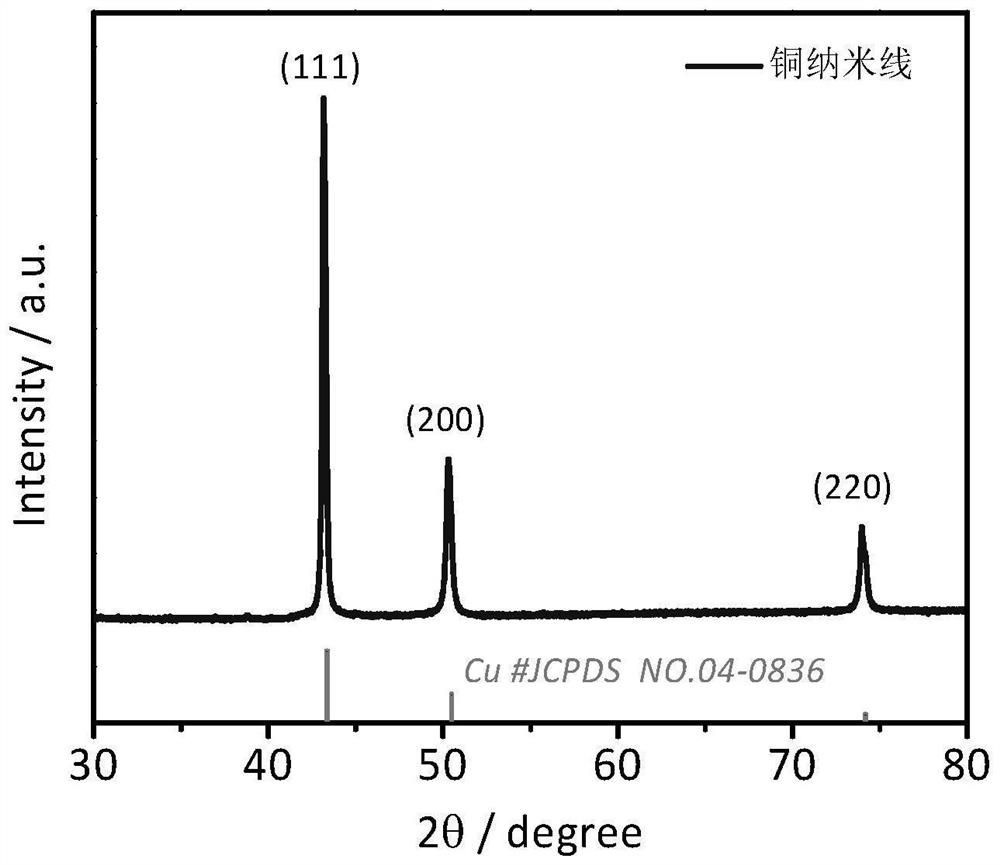

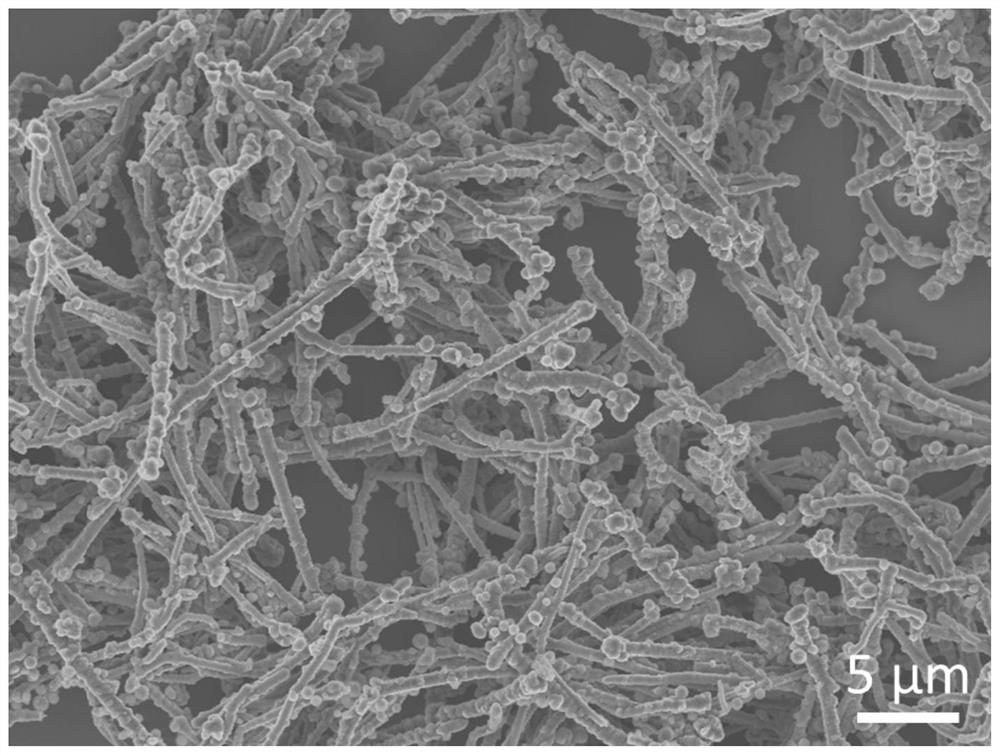

Copper phthalocyanine polymer (at) copper nanowire core-shell nanomaterial and preparation method and application thereof

ActiveCN114427104AGood dispersionSolve easy aggregationElectrolytic organic productionElectrodesPtru catalystPhthalocyanine

The invention belongs to a copper phthalocyanine polymer and copper nanowire core-shell nano material in the field of electrochemical carbon dioxide reduction of a nano material catalyst technology, and a preparation method and application thereof. According to the copper phthalocyanine polymer and copper nanowire core-shell nano material disclosed by the invention, a copper nanowire is used as a copper source and a carrier, and a core-shell structure with the copper nanowire as a core and the copper phthalocyanine polymer as a shell is formed. The preparation method comprises the following steps: firstly, synthesizing a copper nanowire through a hydrothermal method, then putting the copper nanowire into a microwave reactor, enabling copper on the surface of the copper nanowire to be coordinated with a cyano group, and forming a two-dimensional cross-linked network copper phthalocyanine polymer on the surface of the copper nanowire as a template, thereby forming the copper phthalocyanine polymer-copper nanowire core-shell nano material. The method can be applied to electrochemical CO2 reduction.

Owner:SHENZHEN INST OF ADVANCED TECH

A kind of waste power battery environment-friendly recycling method

ActiveCN109244586BHarm reductionAchieve emission reductionWaste accumulators reclaimingBattery recyclingElectrolytic agentPower battery

A method for recycling and reusing waste power battery belongs to that field of recycling waste battery. The battery is completely discharged and placed under a sealed and protective gas atmosphere, and the battery pole head, the shell and the battery cell are collected by cold cutting; the obtained cell is immersed and cleaned in the replacement solution. And the positive electrode, the negativeelectrode and the diaphragm are separated by unwinding; The positive and negative electrode pieces are respectively soaked in distilled water and ultrasonicated to obtain positive and negative electrode materials, aluminum foil and copper foil; The electrolyte volatile in the process of cell disassembly is absorbed by absorption tower. Distillation, condensation, filtration and drying are used forrecycling of the replacement liquid used in the cell immersion process, and the harmful substances are recovered through a neutralization sedimentation tank and a tail gas absorption tank. The ultrasonic liquid is recycled after being precipitated by adding demulsifier, filtered and treated by biological contact oxidation. The invention realizes the recovery and regeneration of the waste lithiumion battery, the process is safe, harmless, the automation degree is high, the treatment is efficient and convenient, and the secondary pollution to the environment is not generated.

Owner:BEIJING UNIV OF TECH

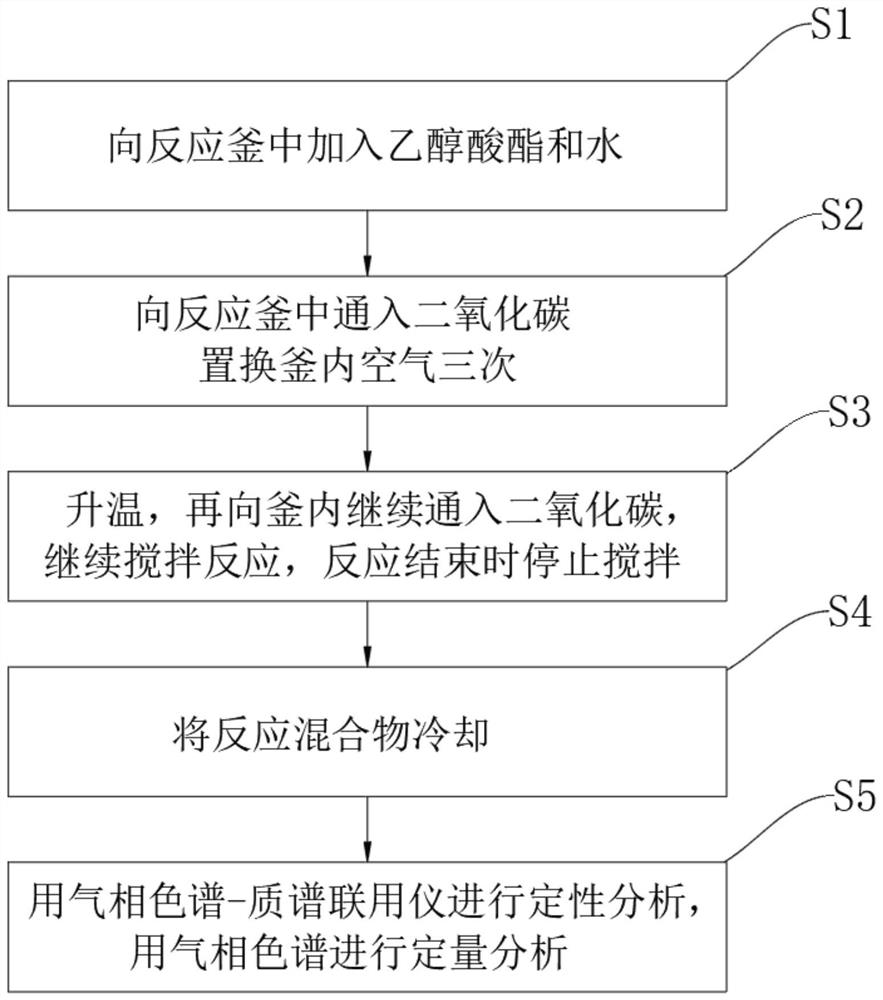

Method for hydrolyzing glycolic acid ester based on carbonic acid system as traceless catalyst

The invention discloses a method for hydrolyzing glycolic acid ester based on a carbonic acid system as a traceless catalyst. The method comprises the following specific preparation steps: S1, adding glycolic acid ester and water into a reaction kettle; S2, introducing carbon dioxide into the reaction kettle to replace air in the kettle three times; S3, raising the temperature, introducing carbon dioxide into the kettle, continuously carrying out the stirring reaction, and stopping stirring when the reaction is finished; S4, cooling the reaction mixture; and S5, carrying out qualitative analysis by using a gas chromatograph-mass spectrometer, and carrying out quantitative analysis by using gas chromatography. According to the invention, under the condition that no other exogenous acid catalyst exists, glycolic acid is prepared by catalyzing a glycolic acid ester aqueous solution through pressurized CO2, a weakly acidic carbonic acid system formed in situ under the reaction condition is used as the catalyst, and after the reaction is finished, the required product can be directly obtained by utilizing the characteristic that the carbonic acid system is spontaneously decomposed into water and CO2 during pressure reduction, so that the step and process of separating the product from the homogeneous / heterogeneous catalyst are omitted, the operation is simple, and the process is efficient and safe.

Owner:上海卓笙环保科技有限公司

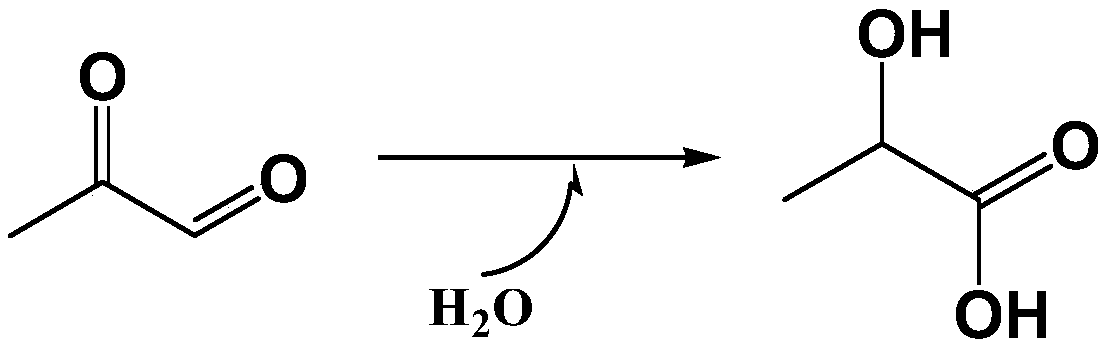

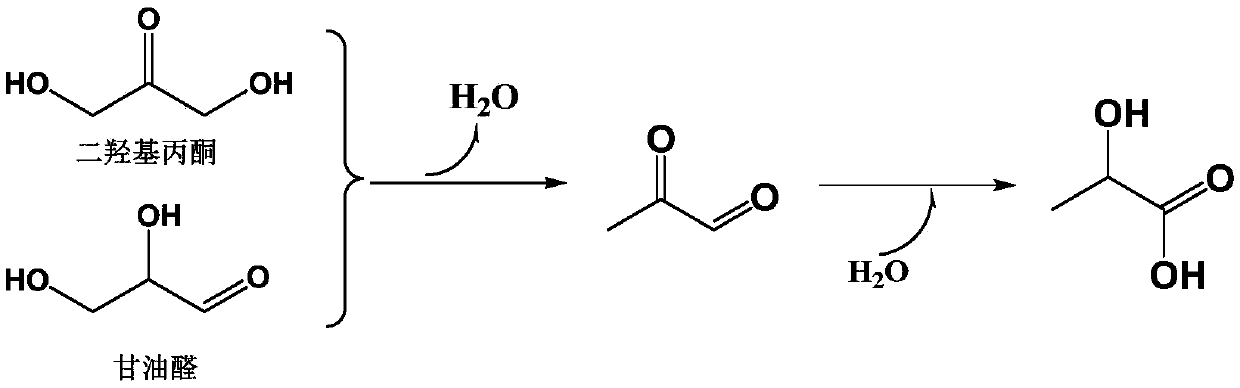

Method for preparing lactic acid by catalyzing pyruvic aldehyde

ActiveCN111253239AImprove conversion rateHigh yieldMolecular sieve catalystsChemical recyclingMolecular sievePtru catalyst

The invention relates to a method for preparing lactic acid by catalyzing pyruvic aldehyde. The method comprises the following steps: contacting pyruvic aldehyde, water and a catalyst in a reactor, and reacting to obtain a product containing lactic acid, wherein the molar ratio of the pyruvic aldehyde to the water is 1:(40-350), the reaction temperature is 30-180 DEG C, the reaction time is 1-10 hours, the catalyst contains a tin-titanium-silicon molecular sieve, and the weight ratio of the pyruvic aldehyde to the tin-titanium-silicon molecular sieve based on dry basis weight is 1:(1-6). The method provided by the invention has high pyruvic aldehyde conversion rate and high lactic acid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ketal glycerine and/or acetal glycerine

ActiveCN111253362AEasy dehydration condensationImprove reaction efficiencyOrganic chemistryMolecular sieve catalystsMolecular sievePolymer science

The invention relates to a method for preparing ketal glycerine and / or acetal glycerine. The method comprises the following steps: contacting glycerine and a reaction raw material with a catalyst in areactor, and reacting to obtain a product containing ketal glycerine and / or acetal glycerine, wherein the reaction raw material contains aldehyde and / or ketone, the molar ratio of glycerine to aldehyde and / or ketone is 1:(1-10), the reaction temperature is 30-180 DEG C, the reaction time is 1-10 hours, the catalyst contains a tin-silicon molecular sieve, and the weight ratio of glycerol to the tin-silicon molecular sieve based on dry basis weight is (1-40):1. The method provided by the invention has high aldehyde / ketone conversion rate and high acetal / ketal glycerine selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing levulose by catalyzing glucose

ActiveCN111253450AImprove conversion rateHigh yieldSugar derivativesSugar derivatives preparationMolecular sieveFructose

The invention relates to a method for preparing levulose by catalyzing glucose. The method comprises the following steps of enabling the glucose to be in contact with a catalyst in a reactor in the presence of alcohol, and performing a reaction to obtain products containing the levulose, wherein the molar ratio of glucose to alcohol is 1 to (50-600), the reaction temperature is 30 DEG C or above and lower than 100 DEG C, and the reaction time is 1-10h. The catalyst contains a tin titanium silicon molecular sieve, wherein the weight ratio of the glucose to the tin titanium silicon molecular sieve in the weight ratio based on dry basis is 1 to (1-6). The method has the advantages of being high in glucose conversion rate and high in yield of levulose.

Owner:CHINA PETROLEUM & CHEM CORP +1

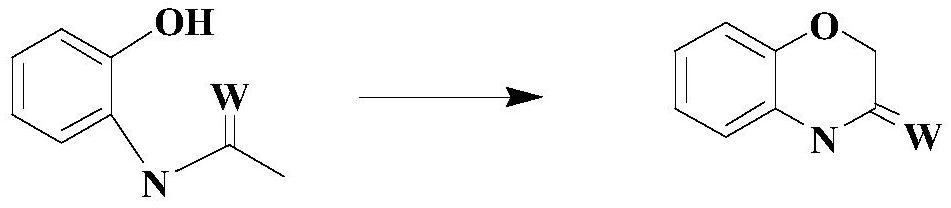

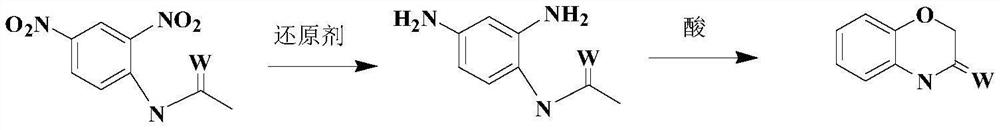

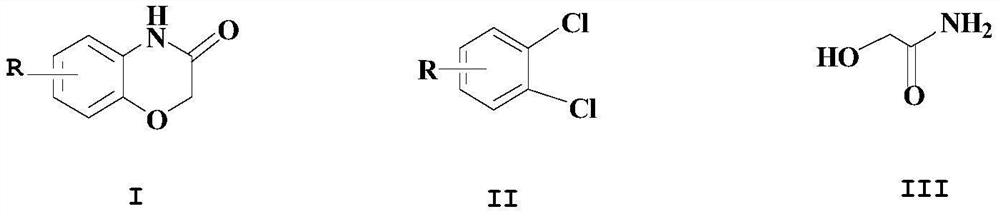

A kind of synthetic technique of 1,4 benzoxazinone compound

The invention relates to a synthesis technology of benzoxazinone compounds represented by formula I. The technology is characterized in that a dichlorobenzene derivative represented by formula II reacts with ethanolamide represented by formula III in the presence of a catalyst and an inorganic alkali to obtain the compound of formula I. R in the formula I and the formula II is selected from hydrogen, an amino group, a nitro group, a C1-6 alkyl group, a C1-6 alkoxy group and a hydroxyl group. The technology is a one-pot reaction method, realizes one-step direct cyclization, and has the advantages of simple reaction conditions, convenience in treatment, safe and highly-effective process, and high yield.

Owner:新昌县勤勉生物医药科技有限公司

System for fragmenting metal ore layer by instantaneous electric pulse and use method

ActiveCN112483086APrecision seamMonitoring data real-timeDisloding machinesPower conversion systemsCapacitanceConverters

The invention provides a system for fragmenting a metal ore layer by instantaneous electric pulse and a use method, and belongs to the technical field of in-situ leaching mining. The system comprisesa transformer, a rectifier, an energy storage capacitor, an energy controller, a discharge electrode and the like, the transformer is connected with the rectifier and used for converting alternating current into direct current, the rectifier is in threaded connection with the energy storage capacitor, the energy storage capacitor is connected with the energy controller, the energy controller is connected with the energy converter, and the energy converter is connected with the discharge electrode and performs an instantaneous electric pulse effect on an ore body, so that the metal ore layer isfragmented. The device is reasonable in structure, convenient to use and capable of effectively increasing gap channels in the in-situ leaching mining process, so that ore leaching liquid is in moresufficient contact with ore, and help is provided for improving the in-situ leaching efficiency.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing lactic acid

ActiveCN111253225AImprove conversion rateHigh yieldMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention relates to a method for preparing lactic acid. The method comprises the following steps of: contacting reaction raw materials, water and a catalyst in a reactor, and reacting to obtain aproduct containing lactic acid, wherein the reaction raw materials contain dihydroxy acetone and / or glyceraldehydes, a molar ratio of dihydroxyacetone and / or glyceraldehydes to water is 1:(50-450), the reaction temperature is 30-180 DEG C, the reaction time is 1-10 hours, the catalyst contains a mixture of a titanium-silicon molecular sieve and a tin-silicon molecular sieve, and the weight ratioof dihydroxy acetone and / or glyceraldehyde to the mixture of the titanium-silicon molecular sieve and the tin-silicon molecular sieve (calculated as dry basis weight) is 1:(0.1-6). The method providedby the invention has high conversion rate of dihydroxyacetone / glyceraldehyde and high yield of lactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

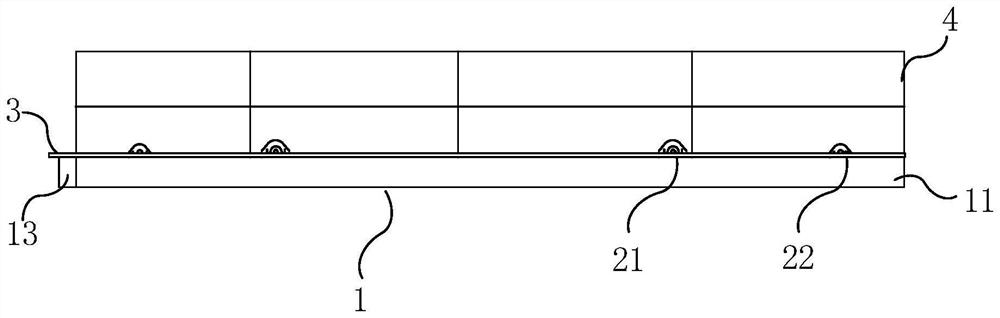

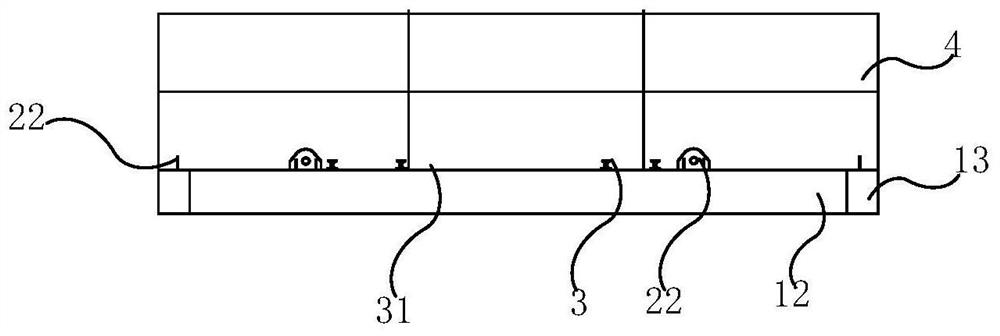

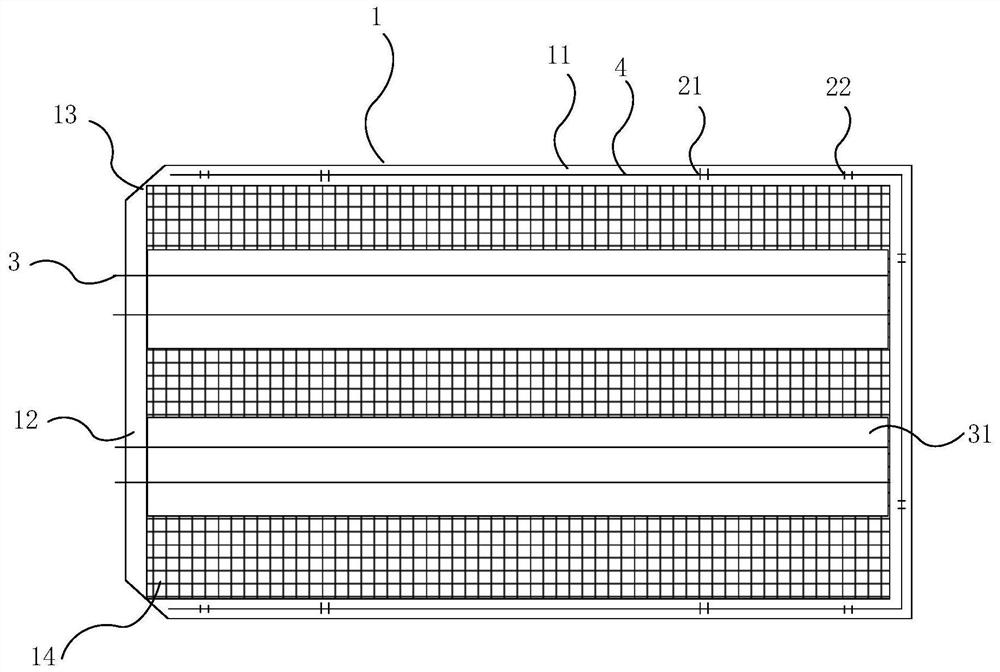

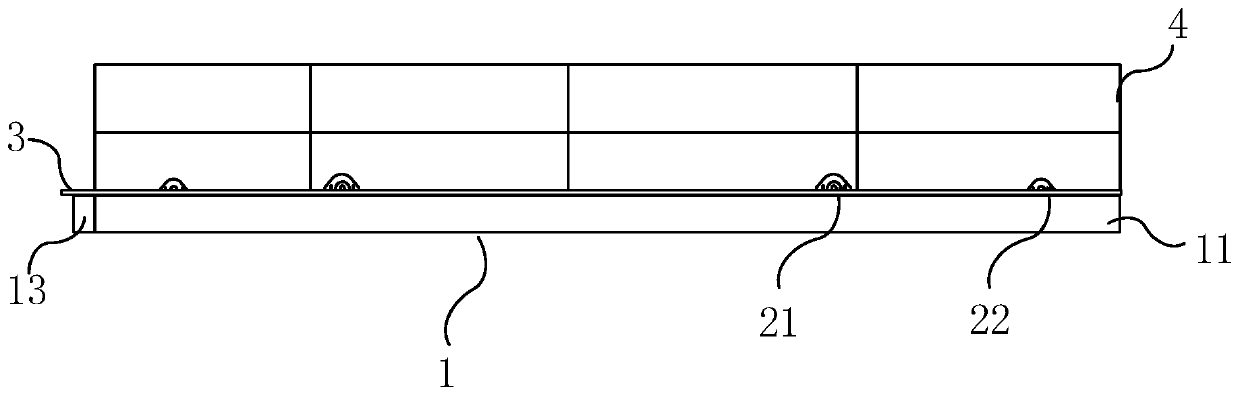

A bracket and method of use thereof

ActiveCN110040620BSafe and efficient processRandom combinationLoad-engaging elementsClassical mechanicsStructural engineering

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Safe tank steaming and washing process for dangerous goods transportation tank car

PendingCN114291042ASolve cleaning problemsThe operation process is clearFatty/oily/floating substances removal devicesDispersed particle separationTank truckSafety control

The invention relates to a safe tank steaming and washing process for a dangerous goods transportation tank car, which comprises the following steps of: S1, opening an oil discharge valve at the rear part of the tank car to control and discharge residual media in the tank, and dismounting a fusing bolt and an anti-overflow probe rod of a sea valve; s2, the tank car is driven into a tank steaming station for tank steaming; s3, after the tank truck finishes steaming, stopping steaming, putting an axial flow fan into a rear manhole, continuously ventilating for more than 30 minutes, and stably reducing the temperature in the tank to below 25 DEG C; s4, cleaning the interior of the tank car; and S5, after cleaning is completed, an automatic drying machine is used for conducting hot air drying on the interior of the tank, after drying is completed, the device is taken out, and a sea bottom valve fusing bolt, an anti-overflow probe rod and the steam cleaning tank are installed. The method is clear in operation process, safe and efficient in process, stable in quality, advanced in safety control measure and cleaning process, capable of effectively solving the cleaning problem of the dangerous goods tank car, free of loopholes in process connection, high in cleaning quality, environment-friendly and efficient in technological process and free of pollution.

Owner:山东京博物流股份有限公司

Bracket and use method thereof

ActiveCN110040620ANot easy to shakeSafe and efficient processLoad-engaging elementsStructural engineering

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com