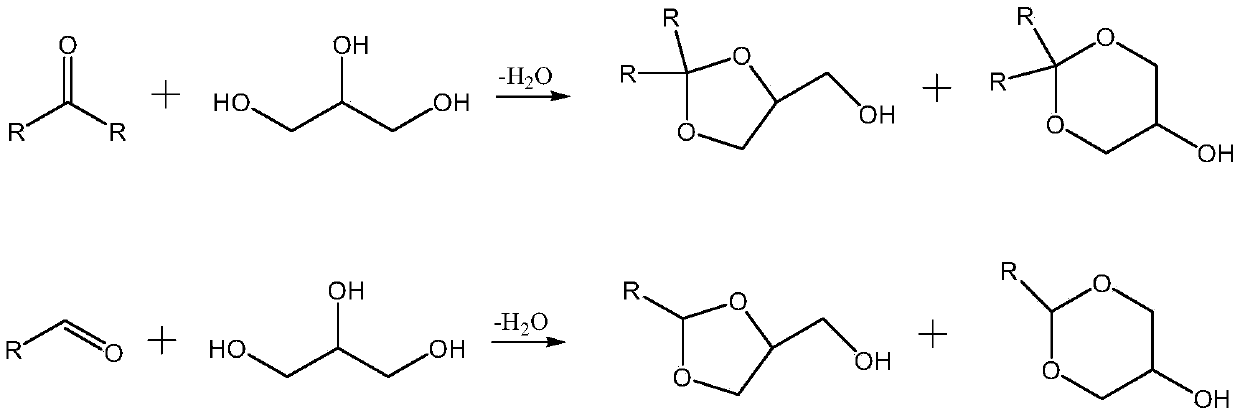

Method for preparing ketal glycerine and/or acetal glycerine

A technology of glycerol aldo and glycerol ketal, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as long reaction time, cumbersome post-processing, and environmental pollution, and achieve high aldehydes /ketone conversion rate, high aldehyde/ketal glycerol yield, and low energy consumption for separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0045] This preparation example prepares Sn-MFI molecular sieve, the specific preparation method is:

[0046] Add tin tetrachloride pentahydrate (SnCl 4 .5H 2 O) Dissolve in water, add this aqueous solution to ethyl orthosilicate (TEOS) and stir, add tetrapropyl ammonium hydroxide (TPAOH, 20% aqueous solution) and water under stirring, and continue stirring for 30 minutes to obtain a chemical composition of 0.03SnO 2 : SiO 2 :0.45TPA:35H 2 The clear liquid of O was then crystallized at 433K for 2 days, then the obtained solid was filtered, washed with distilled water, dried at 393K for 5 hours, and then calcined at 823K for 10 hours to obtain a molecular sieve sample. Among them, the amount of TEOS is 15.31g, the amount of TPAOH is 33.67g, SnCl 4 .5H 2 The amount of O is 0.38g, and the amount of water is 39.64g.

preparation Embodiment 2

[0048] This preparation example refers to "Nemeth L, Moscoso J, Erdman N, et al. Synthesis and characterization of Sn-Beta as a selective oxidation catalyst[J].Studies in Surface Science&Catalysis, 2004,154(04):2626-2631" Methods The Sn-Beta molecular sieve was prepared. The preparation method of the Sn-Beta molecular sieve was as follows:

[0049] Add tin tetrachloride pentahydrate (SnCl 4 .5H 2 O) Dissolve in water, add this aqueous solution to ethyl orthosilicate (TEOS) and stir, add tetraethyl ammonium hydroxide (TEAOH) under stirring, stir until TEOS evaporates to obtain alcohol, add hydrogen fluoride (HF) to the clear liquid , Form a thin layer of paste. Finally, a suspension of dealumination nano Beta seed crystal (20nm) and water was added to obtain a chemical composition of 0.03SnO 2 : SiO 2 : 6TEA: 15H 2 O: 10HF clear liquid, then crystallize at 413K for 10 days, then filter the obtained solid, wash with distilled water, dry at 393K for 5 hours, and then calcined at 823...

preparation Embodiment 3

[0051] This preparation example refers to the literature "Yang X, Wu L, Wang Z, et al. Conversion of dihydroxyacetone to methyl lactate catalyzed by highly active hierarchicalSn-USY at room temperature[J]. Catalysis Science&Technology,2016,6(6):1757- Sn-USY molecular sieve is prepared by the method of 1763". The preparation method of Sn-USY molecular sieve used is:

[0052] The H-USY molecular sieve was mixed with nitric acid, treated at 85°C for 8 hours, the sample was filtered and washed with deionized water, and dried at 120°C for 12 hours to obtain a solid sample. Mix this solid sample with tin tetrachloride pentahydrate (SnCl 4 .5H 2 O) Mix for 1h to obtain a chemical composition of 0.03SnO 2 :100SiO 2 The mixed liquid was dried at 100°C for 12 hours, and finally calcined at 550°C for 3 hours to obtain a molecular sieve sample. Among them, the amount of H-USY is 2.0g, the amount of nitric acid is 50mL, and SnCl 4 .5H 2 The amount of O is 0.6g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com