permeable concrete

A technology of permeable concrete and portland cement, which is applied in the field of building materials, can solve the problems such as the easy decrease of the strength of permeable concrete, and achieve the effect of benefiting cross-linking network, improving compatibility and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

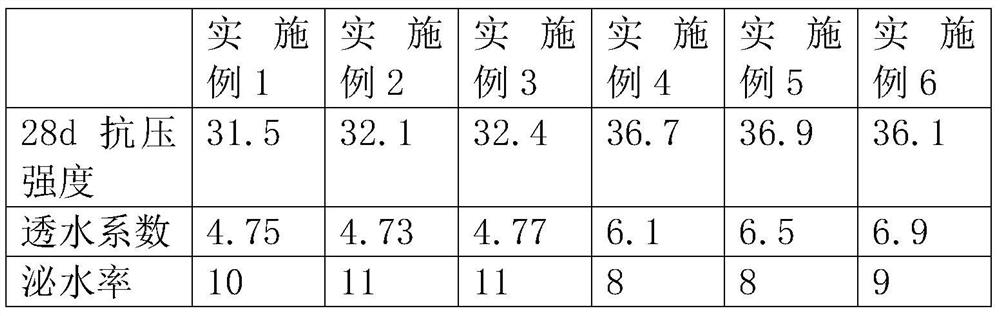

Embodiment 1

[0054] A permeable concrete, comprising the following components in parts by mass:

[0055] Water 4.5kg; Portland cement 15kg; slag powder 32kg; limestone gravel 60kg; water reducing agent 0.75kg; steel fiber 3kg; rubber emulsion 9kg; silane coupling agent 3kg.

[0056] In this embodiment, limestone crushed stone with a particle size of 10 mm is used in Lingshou County Xinyi Mineral Products Processing Plant.

[0057] The preparation method of permeable concrete is as follows:

[0058] (1) In the cement mixer, under normal temperature conditions, add 15kg of Portland cement and stir at a speed of 200r / min;

[0059] (2) Add 4.5kg of water, 0.75kg of water reducing agent, 9kg of rubber emulsion, and 3kg of silane coupling agent while stirring, and after stirring evenly, a premix is obtained;

[0060] (3) In the gravel mixer, under normal temperature conditions, add 32kg of slag micropowder, 60kg of limestone gravel, and 3kg of steel fiber, stir at a speed of 200r / min, and ob...

Embodiment 2

[0063] A permeable concrete, comprising the following components in parts by mass:

[0064] Water 5.25kg; Portland cement 17.5kg; slag fine powder 38kg; limestone gravel 70kg; water reducing agent 0.87kg; steel fiber 4.5kg; rubber emulsion 10.5kg; silane coupling agent 3.5kg.

[0065] In this embodiment, limestone crushed stones with a particle size of 15 mm were used in Lingshou County Xinyi Mineral Products Processing Plant.

[0066] The preparation method of permeable concrete is as follows:

[0067] (1) In the cement mixer, under normal temperature conditions, add 17.5kg of Portland cement and stir at a speed of 200r / min;

[0068] (2) Add 5.25kg of water, 0.87kg of water reducing agent, 10.5kg of rubber emulsion, and 3.5kg of silane coupling agent while stirring, and after stirring evenly, a premix is obtained;

[0069] (3) Add 38kg of slag micropowder, 70kg of limestone gravel, and 4.5kg of steel fiber to the sandstone mixer under normal temperature conditions, stir a...

Embodiment 3

[0072] A permeable concrete, comprising the following components in parts by mass:

[0073] Water 6kg; Portland cement 20kg; slag powder 41kg; limestone gravel 80kg; water reducing agent 1kg; steel fiber 6kg; rubber emulsion 12kg; silane coupling agent 4kg.

[0074] In this embodiment, limestone crushed stones with a particle size of 20 mm from Xinyi Mineral Products Processing Plant in Lingshou County were used.

[0075] The preparation method of permeable concrete is as follows:

[0076] (1) In the cement mixer, under normal temperature conditions, add 20kg of Portland cement and stir at a speed of 200r / min;

[0077] (2) Add water 6kg, water reducer 1kg, rubber emulsion 12kg, silane coupling agent 4kg while stirring, after stirring evenly, obtain the premix;

[0078] (3) In the gravel mixer, under normal temperature conditions, add 41kg of slag micropowder, 80kg of limestone gravel, and 6kg of steel fiber, stir at a speed of 200r / min, and obtain aggregate after stirring ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com