Aluminum paint

A technology of silver powder paint and component A, which is applied in the field of coatings, can solve the problems of easy volatilization, human hazards, and easy odor of paint, and achieve the effect of improving environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

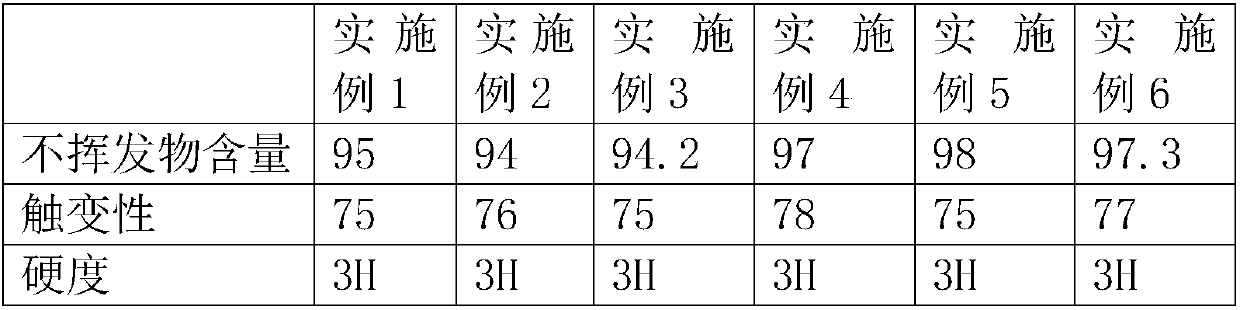

Examples

Embodiment 1

[0051] A silver powder paint consisting of Part A and Part B.

[0052] A component comprises the component of following mass parts:

[0053] 82.5 parts of polyurethane resin; 30 parts of metal powder; 9.9 parts of xylene; 6 parts of butanol; 1.5 parts of activated carbon; 7.5 parts of silane coupling agent; 7.5 parts of polysiloxane;

[0054] Component B includes the following components in parts by mass:

[0055] 9.06 parts of polyurethane curing agent; 9.06 parts of n-butanol.

[0056] In this embodiment, the metal powder is aluminum powder.

[0057] In this embodiment, butanol in component A is n-butanol.

[0058] In this embodiment, the polysiloxane is polydimethylsiloxane.

[0059] The preparation method of silver powder paint is as follows:

[0060] (1) Preparation of component A: In the first reaction kettle of 200L, under normal temperature conditions, add 16.5kg of polyurethane resin as a primer, stir at a speed of 400r / min, and add 30kg of aluminum powder and 1....

Embodiment 2

[0064] A silver powder paint consisting of Part A and Part B.

[0065] A component comprises the component of following mass parts:

[0066] 96.25 parts of polyurethane resin; 35 parts of metal powder; 11.55 parts of xylene; 7 parts of butanol; 1.75 parts of activated carbon; 8.75 parts of silane coupling agent; 8.75 parts of polysiloxane;

[0067] Component B includes the following components in parts by mass:

[0068] 21.1 parts of polyurethane curing agent; 21.1 parts of n-butanol.

[0069] In this embodiment, the metal powder is aluminum powder.

[0070] In this embodiment, butanol in component A is isobutanol.

[0071] In this embodiment, the polysiloxane is polydiethylsiloxane.

[0072] The preparation method of silver powder paint is as follows:

[0073] (1) Preparation of component A: In the 200L first reaction kettle, under normal temperature conditions, add 19.25kg of polyurethane resin as a primer, stir at a speed of 400r / min, add 35kg of aluminum powder and 1....

Embodiment 3

[0077] A silver powder paint consisting of Part A and Part B.

[0078] A component comprises the component of following mass parts:

[0079] 110 parts of polyurethane resin; 40 parts of metal powder; 13.2 parts of xylene; 8 parts of butanol; 2 parts of activated carbon; 10 parts of silane coupling agent; 10 parts of polysiloxane;

[0080] Component B includes the following components in parts by mass:

[0081] 24.15 parts of polyurethane curing agent; 24.15 parts of n-butanol.

[0082] In this embodiment, the metal powder is aluminum powder.

[0083] In this embodiment, butanol in component A is sec-butanol.

[0084] In this embodiment, the polysiloxane is polydipropylsiloxane.

[0085] The preparation method of silver powder paint is as follows:

[0086] (1) Preparation of component A: In the first reaction kettle of 200L, under normal temperature conditions, add 22kg of polyurethane resin as a primer, stir at a speed of 400r / min, add 40kg of aluminum powder, 2kg of acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com