Iron oxide red epoxy aluminum powder anti-rust paint

A red epoxy aluminum and anti-rust paint technology, applied in the field of coatings, can solve the problems of metal corrosion and rust, low elongation, high brittleness, etc., and achieve the effect of improving the anti-rust effect, enhancing the strength and increasing the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

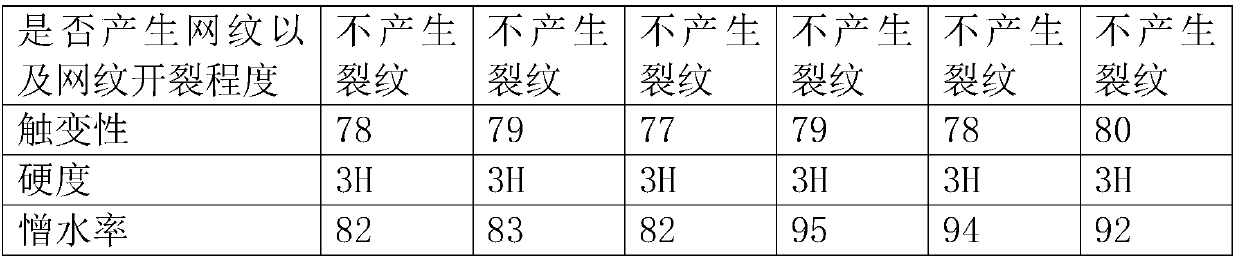

Embodiment 1

[0049] An iron red epoxy aluminum powder antirust paint, which consists of component A and component B.

[0050] Component A includes the following components in parts by mass:

[0051] 52.5 parts of epoxy resin; 21 parts of iron red powder; 27 parts of silver powder; 15 parts of xylene; 4.5 parts of butanol; 3 parts of silane coupling agent; 22.5 parts of polysiloxane;

[0052] Component B includes the following components in parts by mass:

[0053] 17.46 parts of curing agent; 5.82 parts of toughening agent; 5.82 parts of xylene.

[0054] In this embodiment, butanol in component A is n-butanol.

[0055] In this embodiment, the silane coupling agent is A-151.

[0056] In this embodiment, the polysiloxane is polydimethylsiloxane.

[0057] In this embodiment, the curing agent is T31.

[0058] The preparation method of iron red epoxy aluminum powder antirust paint is as follows:

[0059] (1) Preparation of component A: In the first reaction kettle of 200L, under normal tem...

Embodiment 2

[0065] An iron red epoxy aluminum powder antirust paint, which consists of component A and component B.

[0066] Component A includes the following components in parts by mass:

[0067] 61.25 parts of epoxy resin; 24.5 parts of iron red powder; 31.5 parts of silver powder; 17.5 parts of xylene; 5.25 parts of butanol; 3.5 parts of silane coupling agent; 26.25 parts of polysiloxane;

[0068] Component B includes the following components in parts by mass:

[0069] 20.4 parts of curing agent; 6.8 parts of toughening agent; 6.8 parts of xylene.

[0070] In this embodiment, butanol in component A is isobutanol.

[0071] In this embodiment, the silane coupling agent is A-172.

[0072] In this embodiment, the polysiloxane is polydiethylsiloxane.

[0073] In this embodiment, the curing agent is T32.

[0074] The preparation method of iron red epoxy aluminum powder antirust paint is as follows:

[0075] (1) Preparation of component A: In the 200L first reaction kettle, under norma...

Embodiment 3

[0081] An iron red epoxy aluminum powder antirust paint, which consists of component A and component B.

[0082] Component A includes the following components in parts by mass:

[0083] 70 parts of epoxy resin; 28 parts of iron red powder; 36 parts of silver powder; 20 parts of xylene; 6 parts of butanol; 4 parts of silane coupling agent; 30 parts of polysiloxane;

[0084] Component B includes the following components in parts by mass:

[0085] 23.28 parts of curing agent; 7.76 parts of toughening agent; 7.76 parts of xylene.

[0086] In this embodiment, butanol in component A is sec-butanol.

[0087] In this embodiment, the silane coupling agent is KH-560.

[0088] In this embodiment, the polysiloxane is polydipropylsiloxane.

[0089] In this embodiment, the curing agent is T33.

[0090] The preparation method of iron red epoxy aluminum powder antirust paint is as follows:

[0091] (1) Preparation of component A: In the first reaction kettle of 200L, under normal temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com