A method for environmentally friendly recycle and reusing waste pow battery

A power battery and waste technology, which is applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of inability to meet the urgent needs of waste power batteries, low efficiency, small scale, etc., and achieve a reliable recycling process , high efficiency, and harm reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

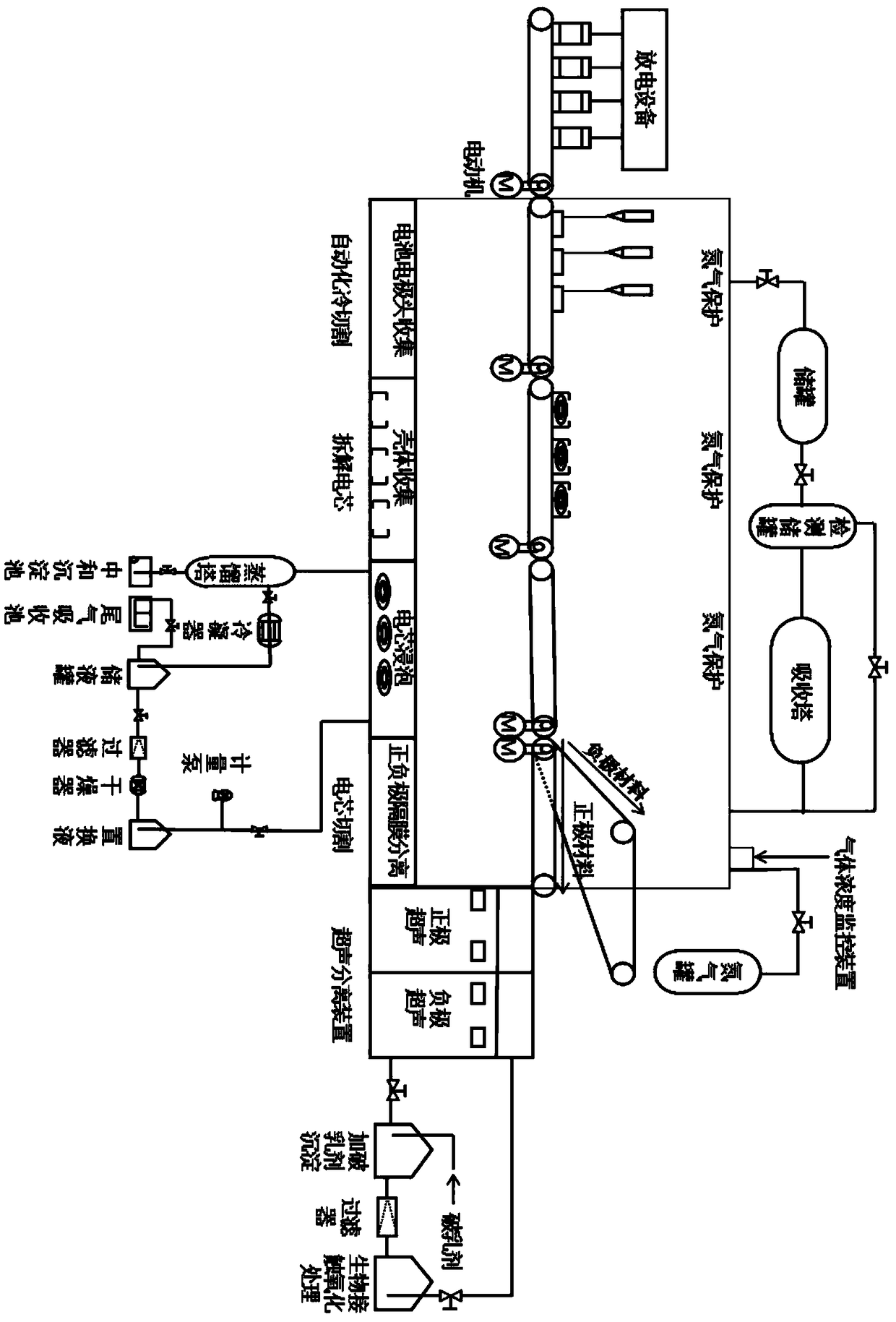

[0031] like figure 1 As shown, the process route of the environmentally friendly recovery and reuse method for waste power batteries in this embodiment includes the following steps:

[0032] a) Fully discharge the battery through safety pretreatment. The discharge device is a high-current charge-discharge instrument. First discharge to 2.5V at a discharge rate of 1C, and then discharge to 0.2V at a rate of 0.2C;

[0033] b) The discharged battery is placed in a nitrogen atmosphere in a sealed box, and the battery is cut along the 3mm below the top groove by the method of local liquid nitrogen spot spraying and cold cutting. Open the battery, take out the battery cell, and the battery terminal Collect directly with shell;

[0034] c) The battery cell taken out in step b) is placed in the DMC replacement solution and soaked for 0.5h under the protective atmosphere condition in the sealed box, so that the electrolyte in the battery cell is fully absorbed;

[0035] d) The cells ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com