Distributed monitoring system for temperature of underground filling body

A technology of distributed monitoring and body temperature, applied in fillings, mining devices, safety devices, etc., to reduce costs, strengthen theoretical and practical value, and process safety and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides an underground filling body temperature distributed monitoring system for the lack of a continuous temperature monitoring system for the paste in the mine stope, the inaccurate connection between the indoor test and the field practice, and the like.

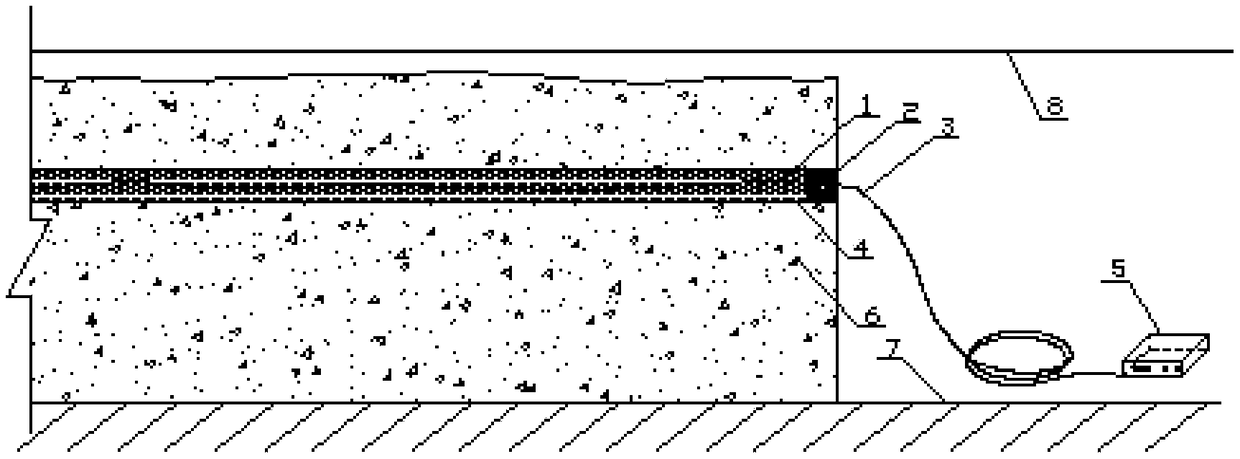

[0026] Such as figure 1 As shown, the system includes an aluminum sleeve 1, a sealant 2, a temperature-sensitive optical fiber 3, a heat-conducting silicone grease 4, and a data collection system 5, wherein the filling body 6 is located between the top plate 8 and the bottom plate 7, and the aluminum sleeve 1 It is located in the drilling hole of the filling body 6; the temperature-sensing optical fiber 3 is placed in the aluminum sleeve 1; the data acquisition system 5 is loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com