A bracket and method of use thereof

A bracket and frame structure technology, applied in the bracket and its application field, to achieve the effect of not being easily shaken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

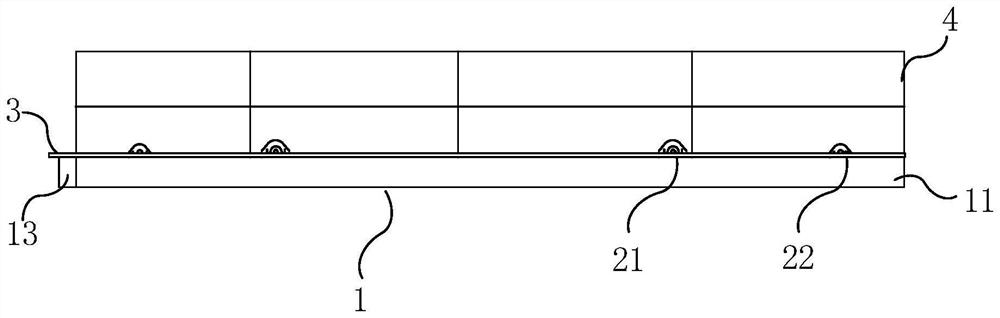

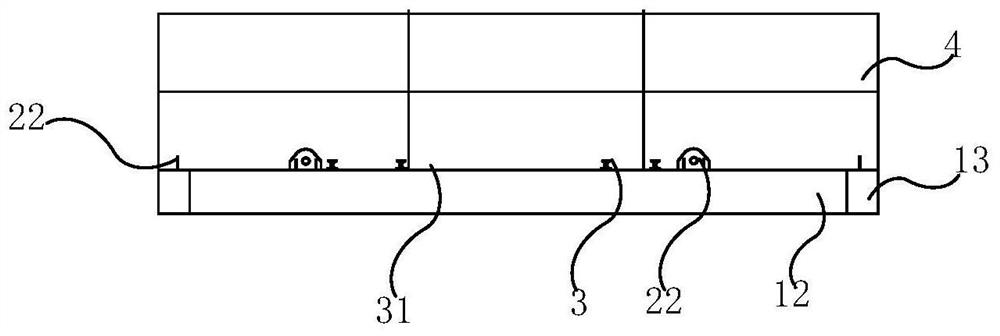

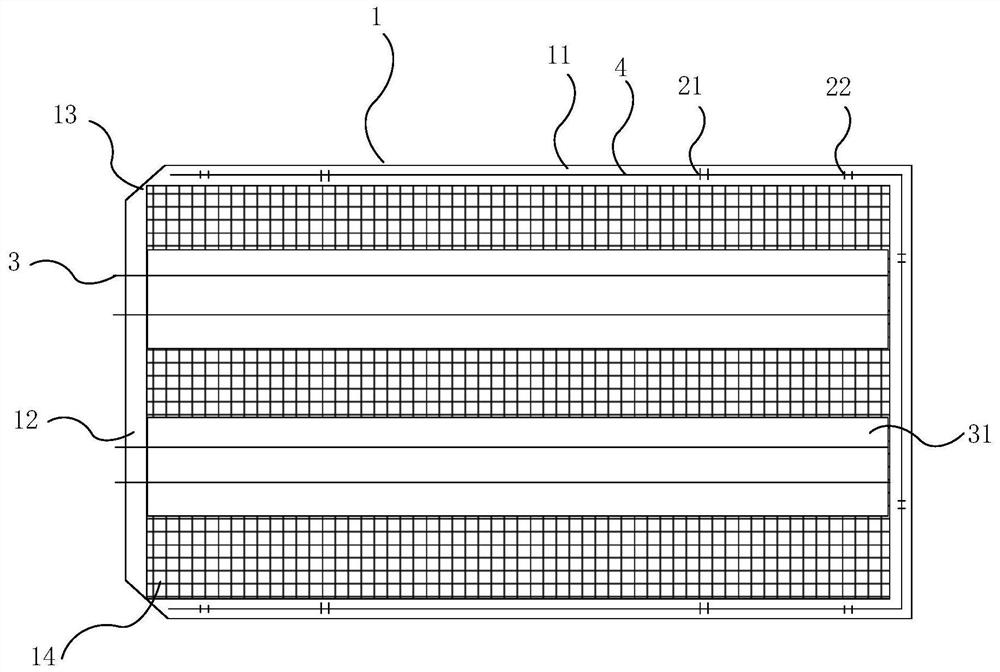

[0038] 1, Figure 1-4 A bracket is shown, which includes a bracket body 1, 10 lifting lugs 21 and 22, 4 slides 3, a grid panel 14, 3 guardrails 4 and a rectangular steel plate 31 for placing the slides; wherein the bracket The main body 1 is welded by I-shaped steel, including a rectangular frame structure composed of 2 long support beams 11 and 2 short support beams 12 and 6 reinforcement plates 15 and 16. The 6 reinforcement plates are divided into two groups and arranged evenly In the middle part of the frame structure; the first set of reinforcing plates 15 has 4 parallel to the short support beam 12, and the top surface of the first set of reinforcing plates 15 is flush with the top surface of the frame structure; the second set of reinforcing plates 16 has 2 Parallel to the long support beam 11, it is arranged below the first group of reinforcement plates 15 and welded at the intersection with the bottom end surface of the first group of reinforcement plates 15, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com