System for fragmenting metal ore layer by instantaneous electric pulse and use method

A technology of electric pulse and mine seam, which is applied in the direction of electrical components, earthwork drilling and output power conversion devices, etc., to achieve the effects of long life cycle, low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides a system and application method for breaking a metal ore layer by an instantaneous electric pulse.

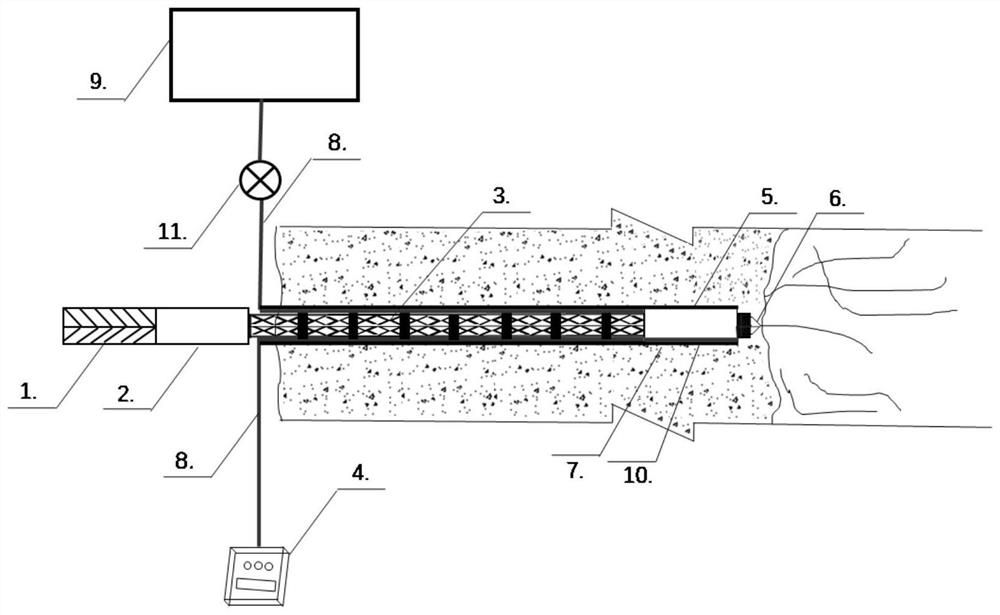

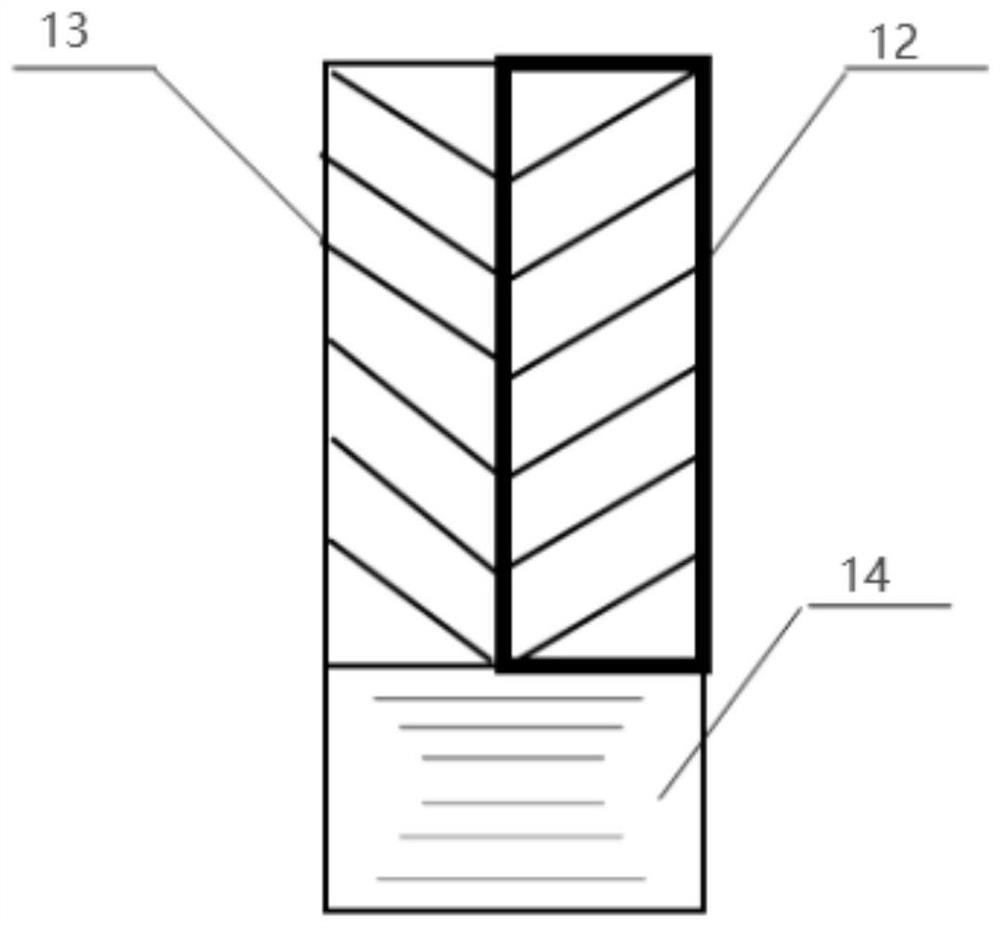

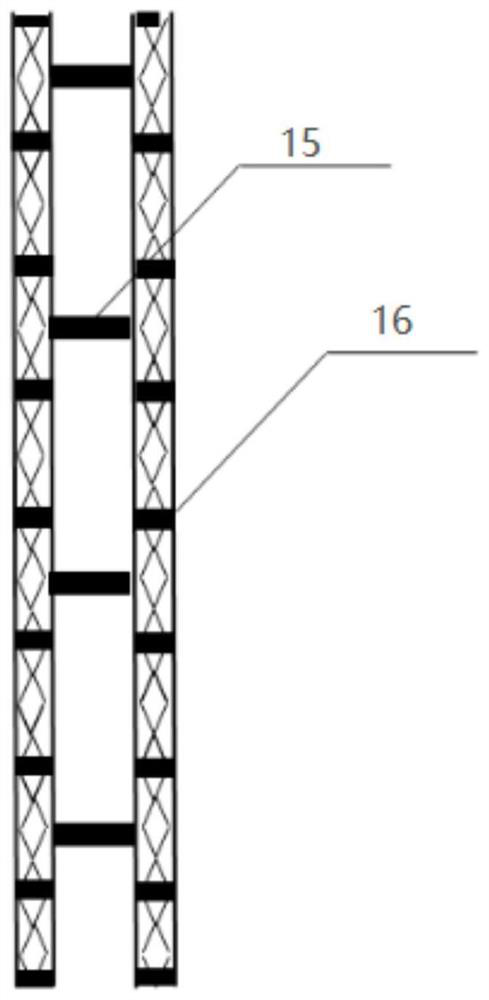

[0031] Such as figure 1 As shown, the system includes a transformer 1, a rectifier 2, an energy storage capacitor 3, an energy controller 4, an energy converter 5, a discharge electrode 6, a bushing protection device 7, a transmission data line 8, a data analysis system 9, and a data acquisition instrument 10 and a pressure gauge 11, wherein the transformer 1 is connected with the rectifier 2 for converting alternating current into direct current, the rectifier 2 is connected with the energy storage capacitor 3 through threads, the energy storage capacitor 3 is connected with the energy controller 4, and the energy controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com