In-situ leaching instantaneous high-pressure gas pulse fracture forming system and using method thereof

A high-pressure gas and leaching technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., to achieve the effect of safe and efficient process, strong theoretical and practical value, and long life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides an in-situ leaching instantaneous high-pressure gas pulse seam-making system and a use method thereof.

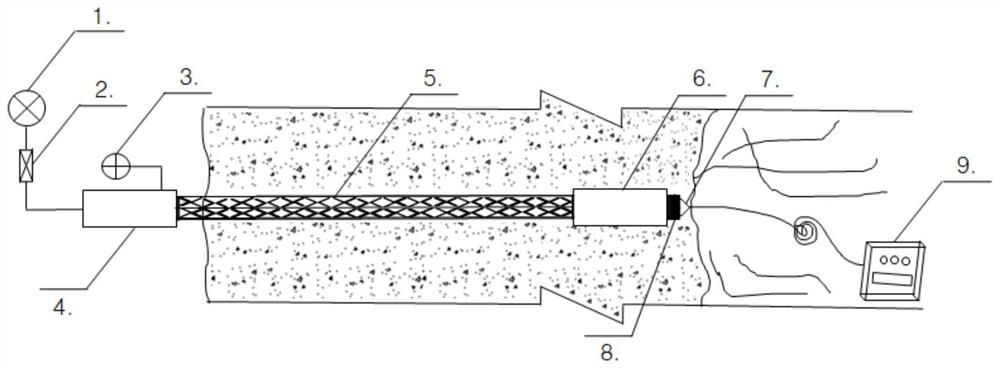

[0026] Such as figure 1 As shown, the system includes a gas storage tank 1, a check valve 2, a pressure gauge 3, an air compressor 4, a steel pipe 5, a pulse controller 6, a pressure-sensitive optical fiber instrument 7, a sealant 8, and a data acquisition system 9. The tank 1 is connected with the air compressor 4, the one-way valve 2 is located at the connection between the air storage tank 1 and the air compressor 4, the pressure gauge 3 is located outside the device and connected with the air compressor 4, and the pulse controller 6 is connected with the air compressor 4 , the pressure-sensitive optical fiber instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com