Integrated biogas desulfurizing device and method

A biogas desulfurization and biogas technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of flammability and explosion, microbial decay and death, and clogging of the reaction system, and achieves low operating costs and continuous and stable discharge. , the effect of investment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

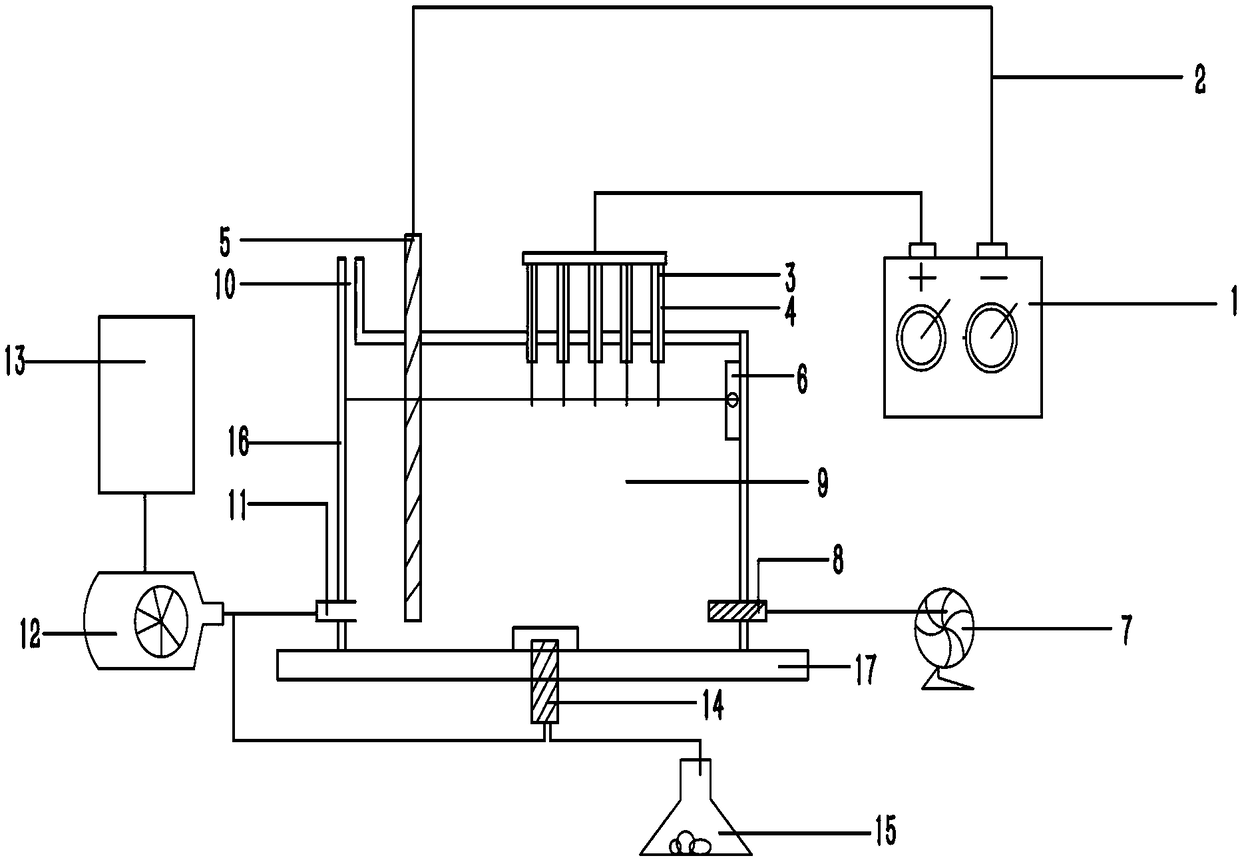

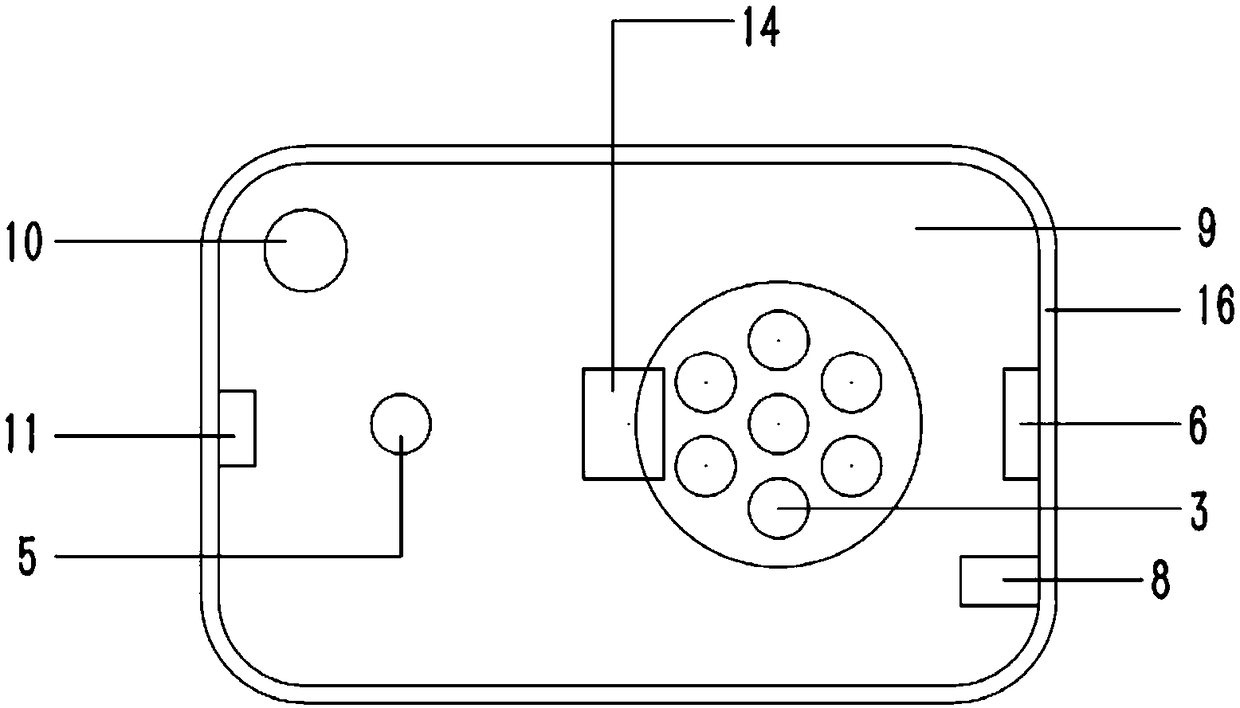

[0034] The biogas enters the reaction pool 9 through the fan 7 from the gas collection outlet 8, and the reaction pool contains Fe 3+ The absorption liquid quickly absorbs the hydrogen sulfide in the biogas; start the high-voltage DC power supply 1, and the high-voltage electrode 3 is immersed in the liquid surface of the absorption liquid for 3mm to directly discharge the liquid phase, and the gas that reaches the standard is discharged from the upper gas outlet 10; The liquid port 11 blows the hydrogen peroxide stored in the liquid storage tank 13 into the reaction tank 9 through the circulation pump 12, and the liquid level detector 6 determines the amount of regeneration liquid that needs to be supplemented.

Embodiment 2

[0036] The biogas enters the reaction pool 9 through the fan 7 from the gas collection outlet 8, and the reaction pool contains Fe 3+ The absorption liquid quickly absorbs the hydrogen sulfide in the biogas; start the high-voltage DC power supply 1, extend the low-voltage end into the liquid surface of the absorption liquid, and immerse the high-voltage electrode 3 into the liquid surface of the absorption liquid for 5mm to directly discharge the liquid phase, and the gas after reaching the standard is discharged from the upper gas outlet 10 discharge; in the working process, the hydrogen peroxide stored in the liquid storage tank 13 is blown into the reaction tank 9 from the liquid inlet 11 through the circulation pump 12, and the liquid level detector 6 judges the amount of regenerating liquid that needs to be supplemented.

Embodiment 3

[0038] The biogas enters the reaction pool 9 through the fan 7 from the gas collection outlet 8, and the reaction pool contains Fe 3+ The absorption liquid quickly absorbs the hydrogen sulfide in the biogas; start the high-voltage DC power supply 1, and the high-voltage electrode 3 is immersed in the liquid surface of the absorption liquid 4mm to directly discharge the liquid phase, and the gas that reaches the standard is discharged from the gas outlet 10 above; during the working process, from the inlet The liquid port 11 blows the hydrogen peroxide stored in the liquid storage tank 13 into the reaction tank 9 through the circulation pump 12, and the liquid level detector 6 judges the amount of regeneration liquid that needs to be supplemented. The bottom flows out and is separated from the solid and liquid by the filtration system 14. The sulfur element enters the solid tank 15, and the remaining absorption liquid returns to the reaction tank 9 for further use.

[0039] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com