Umami enhancer as well as preparation method and application thereof

An enhancer, umami technology, applied in application, food ingredients as taste modifier, food drying and other directions, can solve problems such as affecting human health, difficult to control Maillard reaction, reducing food quality, etc., to achieve good application prospects, High industrial application value and the effect of enhancing umami intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A umami enhancer, prepared by the following steps:

[0058] Dissolve 10g of glutamic acid and 100g of glucose in 1000g of water, adjust the pH value of the solution to 9.0, and then place it in a -20°C environment for pre-freezing (2-5h). , the obtained dry product was quickly placed in a constant temperature oven, heated at 90°C for 40 minutes, and then cooled in an ice bath to terminate the reaction, and the umami enhancer was obtained.

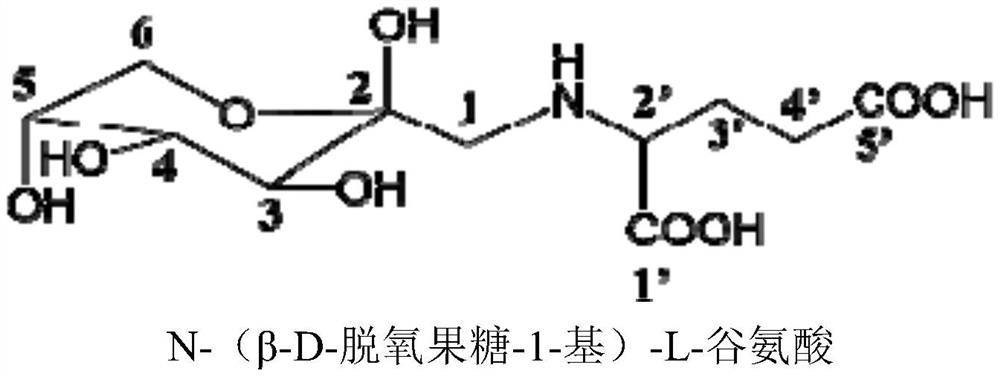

[0059] Gained solid product is dissolved in water, analyzes the primary and secondary mass spectrograms (such as figure 1 , figure 2 shown). The sample is simply separated and processed (such as macroporous resin or ion chromatography, HILIC chromatographic separation, etc.) to remove excess sugar and then analyzed by nuclear magnetic resonance to obtain a nuclear magnetic pattern ( image 3 , Figure 4 ), the molecular structure of the deduced product is as follows:

[0060]

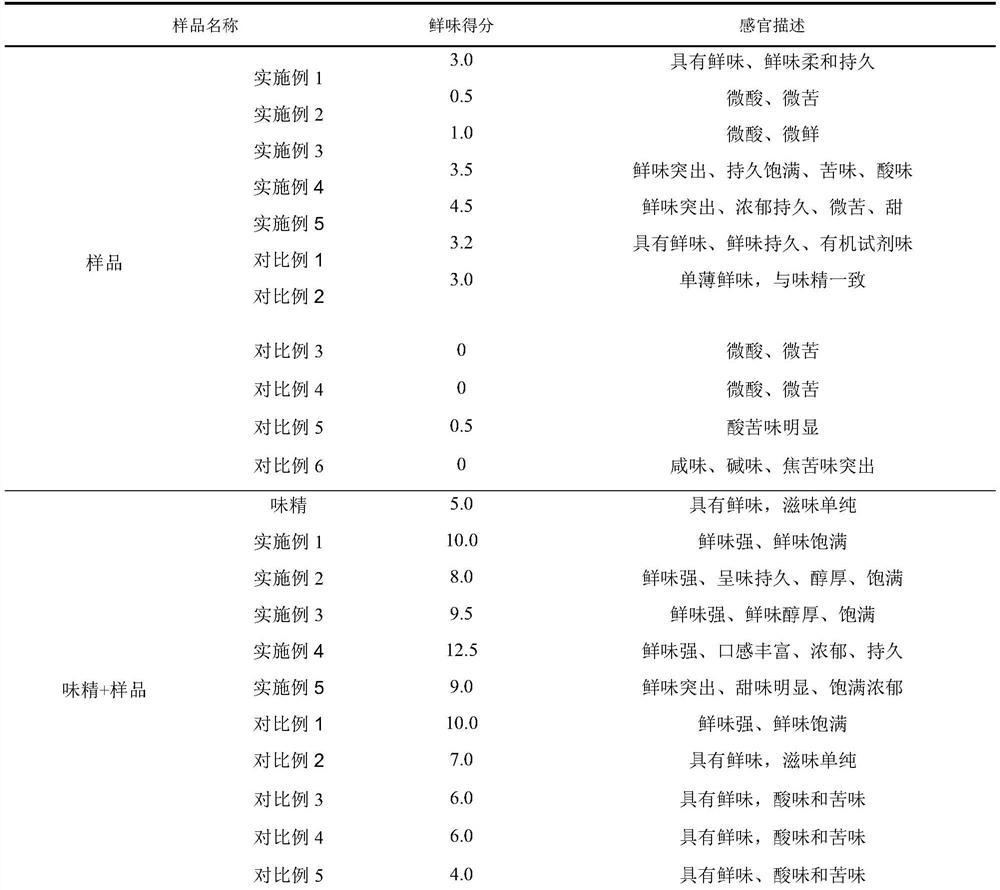

[0061] In order to explore the influence of eac...

Embodiment 2

[0074] A umami enhancer, prepared by the following steps:

[0075] Dissolve 10g of carnosine and 100g of glucose in 1000g of water without adjusting the pH value (after the carnosine is dissolved, the pH of the solution system is generally between 8-9), and pre-freeze at -20°C for 2-4 hours. After the pre-freezing is completed, the sample After vacuum freeze-drying at -45°C for 12 hours, the obtained dried product was quickly placed in a constant temperature oven and heated at 80°C for 90 minutes, and then cooled in an ice bath to terminate the reaction to obtain the umami enhancer.

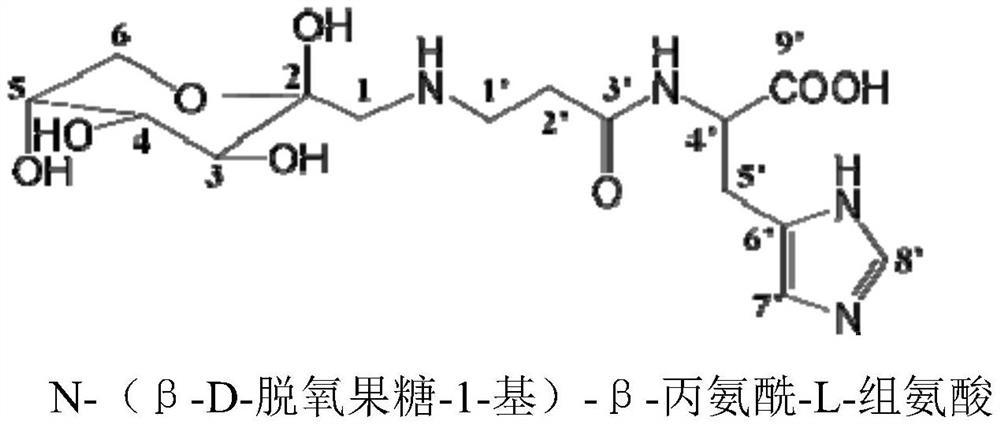

[0076] Gained solid product is dissolved in water, analyzes the primary and secondary mass spectrograms (such as Figure 11 , Figure 12 shown). The sample is simply separated and processed (such as macroporous resin or ion chromatography, HILIC chromatographic separation, etc.) to remove excess sugar, and then perform nuclear magnetic resonance analysis to obtain a nuclear magnetic pattern ( ...

Embodiment 3

[0079] A umami enhancer, prepared by the following steps:

[0080] (1) The umami octapeptide: Ser-Ser-Arg-Asp-Glu-Gln-Ser-Arg polypeptide was synthesized by solid phase synthesis. Swell and wash 1 g of dichloro resin, remove the Fmoc protecting group, add amino acid for condensation reaction, repeat the deprotection-condensation process until all amino acids are connected. Cleavage the resin to obtain the crude polypeptide Ser-Ser-Arg-Asp-Glu-Gln-Ser-Arg, and purify it by reverse-phase high performance liquid chromatography to obtain the pure polypeptide.

[0081](2) Dissolve 1g of synthetic umami peptide and 5g of glucose in 100g of water, adjust the pH value of the solution to 7.0, and place the sample in an environment of -20°C for 2-4 hours to pre-freeze. After vacuum freeze-drying for 8 hours and then frozen for 2 hours, the dried product was quickly placed in a constant temperature oven and heated at 100°C for 80 minutes. After the reaction was completed, the reaction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com