Method for synthesizing MOF derivative semiconductor heterojunction material by solvothermal method

A solvothermal method and MOF technology are applied in the preparation of MOF derivative semiconductor heterojunction materials and the preparation of new catalytic materials. Harsh and other problems, to achieve broad scientific research and practical value, suitable for large-scale mass production, the effect of simple instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

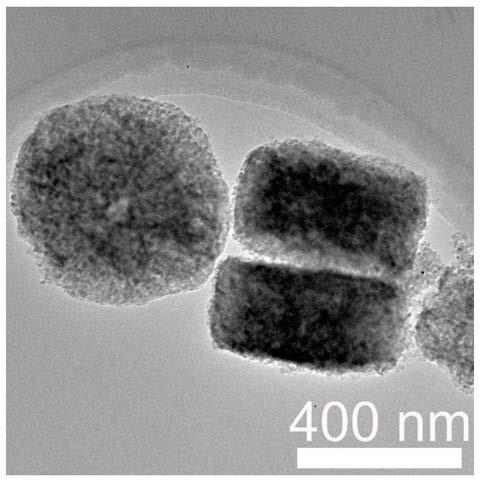

Image

Examples

Embodiment 1

[0034] At 25°C, weigh 2.49g of terephthalic acid (PTA) (15mmol) and 2.56mL of tetra-n-butyl titanate (7.5mmol) in 45mL of N,N-dimethylformaldehyde containing 0.87mL of acetic acid (15mmol). Amide (DMF) and 5mL of anhydrous methanol, placed in an ultrasonic machine, mixed and stirred until completely dissolved, transferred to a crystallization kettle, crystallized at 180°C for 16h, after the crystallization was completed, centrifuged and dried for 24h to obtain MIL-125 material; then calcined in a muffle furnace: first, the heating rate is 0.5-1°C / min, raised to 250-300°C, and kept for 0.5-1.5h; then, the heating rate is 0.5-2°C / min, raised to 450 -480°C, keep warm for 0.5-1.5h, and soak the product (1mmol) in a solution containing Sr(OH) 2 8H2O (1mmol) in 10mL deionized water, 10mL ethylene glycol, 2mL 1,2-propanediol and 2g tetrabutylammonium hydroxide solution (TBAH, 25wt), transferred to a crystallization kettle, crystallized at 160°C for 4h, crystallized After the chemica...

Embodiment 2

[0036] At 25°C, weigh 2.49g of terephthalic acid (PTA) (15mmol) and 2.56mL of tetra-n-butyl titanate (7.5mmol) in 45mL of N,N-dimethylformaldehyde containing 0.87mL of acetic acid (15mmol). Amide (DMF) and 5mL of anhydrous methanol, placed in an ultrasonic machine, mixed and stirred until completely dissolved, transferred to a crystallization kettle, crystallized at 180°C for 16h, after the crystallization was completed, centrifuged and dried for 24h to obtain MIL-125 material; then calcined in a muffle furnace: first, the heating rate is 0.5-1°C / min, raised to 250-300°C, and kept for 0.5-1.5h; then, the heating rate is 0.5-2°C / min, raised to 450 -480°C, keep warm for 0.5-1.5h, soak the product (1mmol) in a solution containing Fe(OH) 2 (1mmol) in 10mL deionized water, 10mL ethylene glycol, 2mL 1,2-propanediol and 2g tetrabutylammonium hydroxide solution (TBAH, 25wt), transferred to a crystallization kettle, crystallized at 160°C for 4h, and the crystallization was completed F...

Embodiment 3

[0038] At 25°C, weigh 2.49g of terephthalic acid (PTA) (15mmol) and 2.56mL of tetra-n-butyl titanate (7.5mmol) in 45mL of N,N-dimethylformaldehyde containing 0.87mL of acetic acid (15mmol). Amide (DMF) and 5mL of anhydrous methanol, placed in an ultrasonic machine, mixed and stirred until completely dissolved, transferred to a crystallization kettle, crystallized at 180°C for 16h, after the crystallization was completed, centrifuged and dried for 24h to obtain MIL-125 material; then calcined in a muffle furnace: first, the heating rate is 0.5-1°C / min, raised to 250-300°C, and kept for 0.5-1.5h; then, the heating rate is 0.5-2°C / min, raised to 450 -480°C, keep warm for 0.5-1.5h, and soak the product (1mmol) in a solution containing Ba(OH) 2 (1mmol) in 10mL deionized water, 10mL ethylene glycol, 2mL 1,2-propanediol and 2g tetrabutylammonium hydroxide solution (TBAH, 25wt), transferred to a crystallization kettle, crystallized at 160°C for 4h, and the crystallization was complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com