Method and device for preparing highly-pure capsicum pigment capsaicin through supercritical fluid column chromatography

A technology for supercritical fluid and capsaicin, which is applied in the field of supercritical fluid column chromatography to separate and prepare high-purity natural products, and in the field of supercritical fluid preparative chromatography, which can solve unseen problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

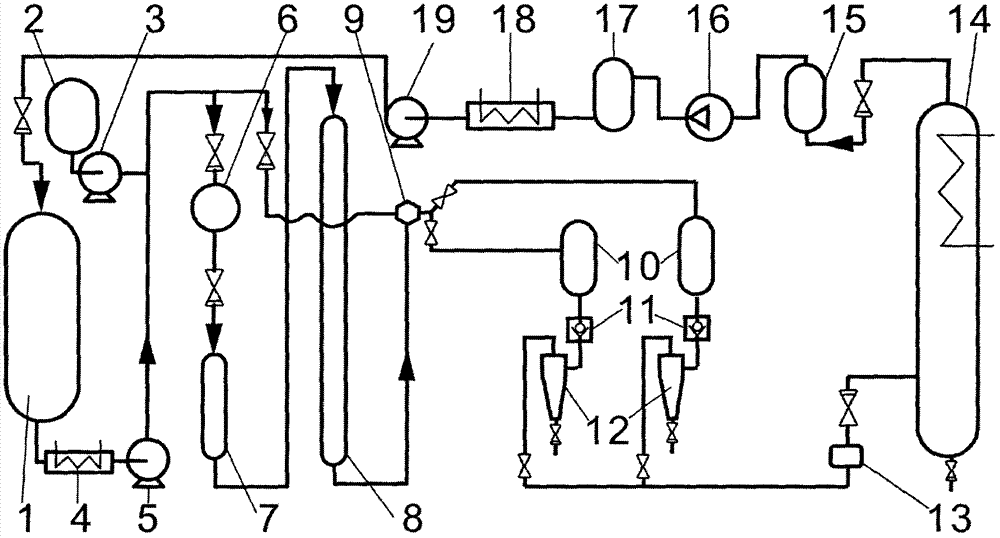

[0062] The pigment pepper extract produced by parallel organic solvent countercurrent extraction is used as raw material, and various pigment compounds are extracted and separated from it. The total capsaicin content in the raw material is 0.08%, and the color value is 235. The filter column is filled with 20 μm silica gel with a diameter of 100 mm and a column length of 200 mm. The separation column is filled with 50 μm silica gel with a diameter of 200 mm and a column length of 1800 mm. The adsorption column packing is activated carbon. The composition of fractions was monitored by an online ultraviolet detector, and the detection wavelength was set at 460 nm. The feeding tank is equipped with a preheating system, and the chromatographic column is equipped with a temperature control and balance system.

[0063] A single-channel batch supercritical chromatographic preparation process is used.

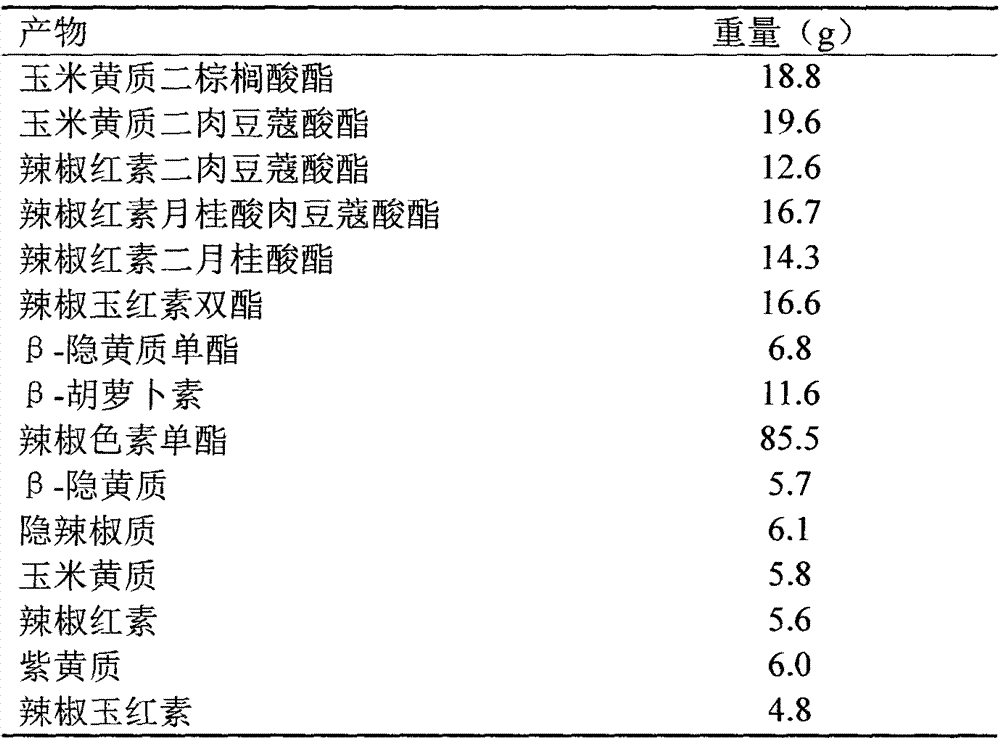

[0064] This example mainly prepares solvent-free high-purity pigment compounds....

Embodiment 2

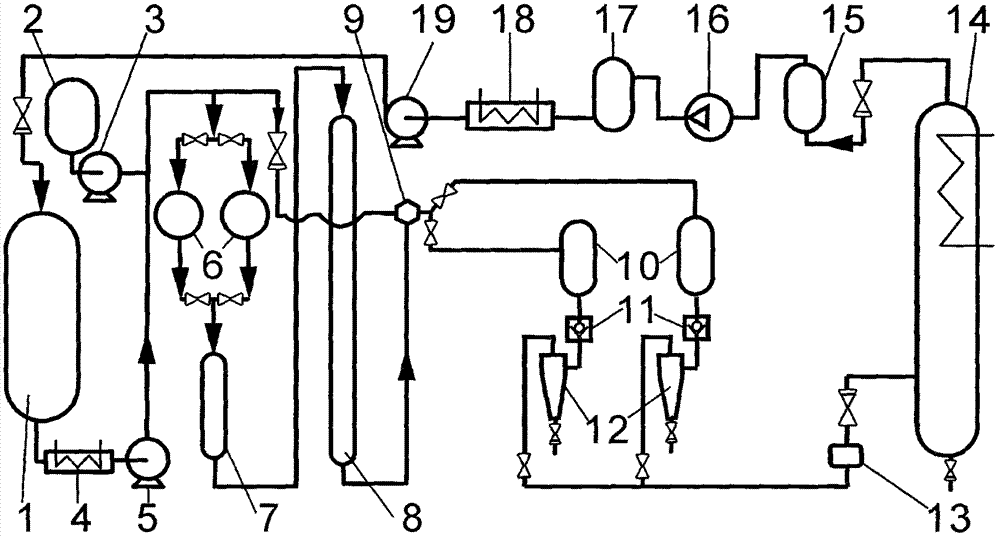

[0074] The capsicum crude extract (capsaicin content 10%, color value 62) that 20Kg horizontal rotation extractor countercurrent extraction obtains is mixed with 20Kg50% ethanol / water, it is heated and saponified with 4Kg10% sodium hydroxide, and saponification temperature is controlled at 40-60°C, after saponification for 1-2h, cool and stand still, and separate and obtain 2.6Kg of saponified product in the upper layer. With this saponification product as raw material, a dual-channel supercritical fluid column chromatography preparation system ( figure 2 ) Continuously prepare high-purity capsaicin and capsaicin.

[0075] Put 1Kg of the saponification product above into a group of batch feeding tanks, the chromatographic column filler is 50 μm silica gel particles, and the adsorption column filler is activated carbon. Adjust the temperature of the feeding tank to 32°C, and increase the pressure to 28MPa. The raw material is dissolved and carried into the chromatographic col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com