Method for preparing levulose by catalyzing glucose

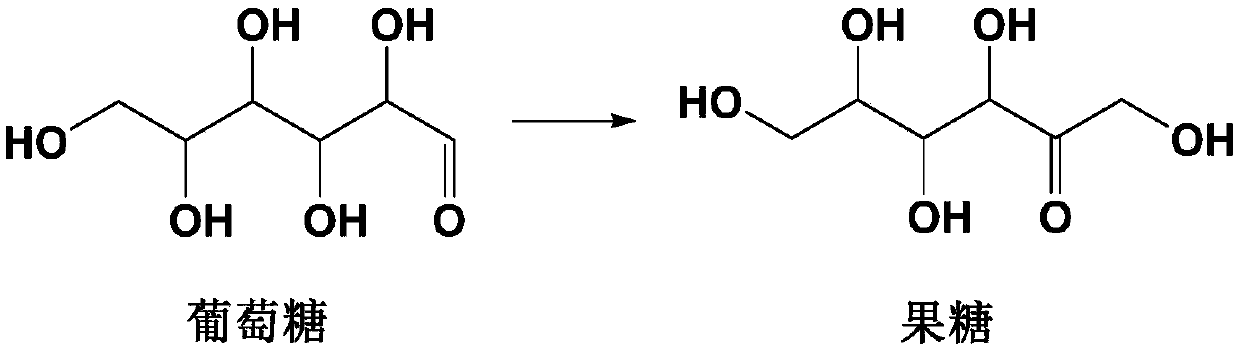

A technology for glucose and fructose, applied in the preparation of sugar derivatives, chemical instruments and methods, monosaccharides, etc., can solve the problems of low percentage of crystalline fructose, long process flow, etc., and achieve high fructose yield and process safety. Efficient, high glucose conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to the first embodiment, preferably the tin-titanium-silicon molecular sieve is at 460 cm in the FT-IR spectrum -1 、975cm -1 、800cm -1 and 1080cm -1 There is absorption nearby. Preferably, the tin-titanium-silicon molecular sieve has absorption at 200-300 nm in the UV-Vis spectrum, preferably at 200-260 nm.

[0051] According to the first embodiment, preferably the molar ratio of the tin element to the silicon element in the tin-titanium-silicon molecular sieve is 0.05-10:100, more preferably 0.1-5:100, particularly preferably 0.2-2:100. Preferably, the molar ratio of titanium element to silicon element in the tin-titanium-silicon molecular sieve is 0.05-10:100, more preferably 0.1-5:100, particularly preferably 0.5-4:100. Such proportions of tin, titanium and silicon can further optimize the catalytic activity of the tin-titanium-silicon molecular sieve of the present invention.

[0052] According to the first embodiment, it is preferred that the tin-tit...

preparation Embodiment 1

[0097] In this preparation example, a Sn-Ti-MFI-1 molecular sieve is prepared according to the method of Example 1 of the Chinese patent CN 105217645A specification, and the specific preparation method is as follows:

[0098] (1) At 25°C, stirring and contacting tetrapropylammonium hydroxide aqueous solution (concentration: 15% by weight) with tetrabutyl titanate and tin tetrachloride pentahydrate for 30 minutes to obtain a mixture;

[0099] (2) At 60°C, add silicon molecular sieve S-1 to the above mixture and stir for 0.5h to obtain the mixture (during this contact process, add water or not add water as required, if the feeding in step (1) can meet the requirement of water Feeding requirements, there is no need to add water, if it is not met, you can add water when the mixture containing tetrapropylammonium hydroxide, tetrabutyl titanate and tin chloride is stirred and contacted with silicon molecular sieve, or distill off water, and the rest The preparation examples are simi...

preparation Embodiment 2

[0103] This preparation example prepares the Sn-Ti-MFI-2 molecular sieve according to the method of the Chinese patent CN105217645A specification example 2, and the specific preparation method is as follows:

[0104] (1) At 25°C, stirring and contacting tetrapropylammonium hydroxide aqueous solution (concentration: 20% by weight) with tetrabutyl titanate and tin tetrachloride pentahydrate for 30 minutes to obtain a mixture;

[0105] (2) At 25°C, add silicon molecular sieve S-1 to the above mixture and stir for 0.5h to obtain the mixture; wherein, ensure that the molar ratio of each substance is: silicon source (silicon molecular sieve): alkali source template (four Propyl ammonium hydroxide): titanium source (tetrabutyl titanate): tin source (tin tetrachloride): water=100:15:2:0.1:200, wherein the silicon source is SiO 2 In terms of titanium source as TiO 2 Tin source is calculated as tin element;

[0106] (3) Transfer the above mixture into a sealed stainless steel reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com