Bottom grout injection system and method suitable for deep well grounding electrode feed bar

A grouting system and grounding electrode technology, applied in the direction of connection contact material, infrastructure engineering, construction, etc., can solve the problems of small hole diameter of deep well grounding electrode, many equipment, and inability to use direct landfill, etc., and the grouting time can be achieved. control, grouting amount controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

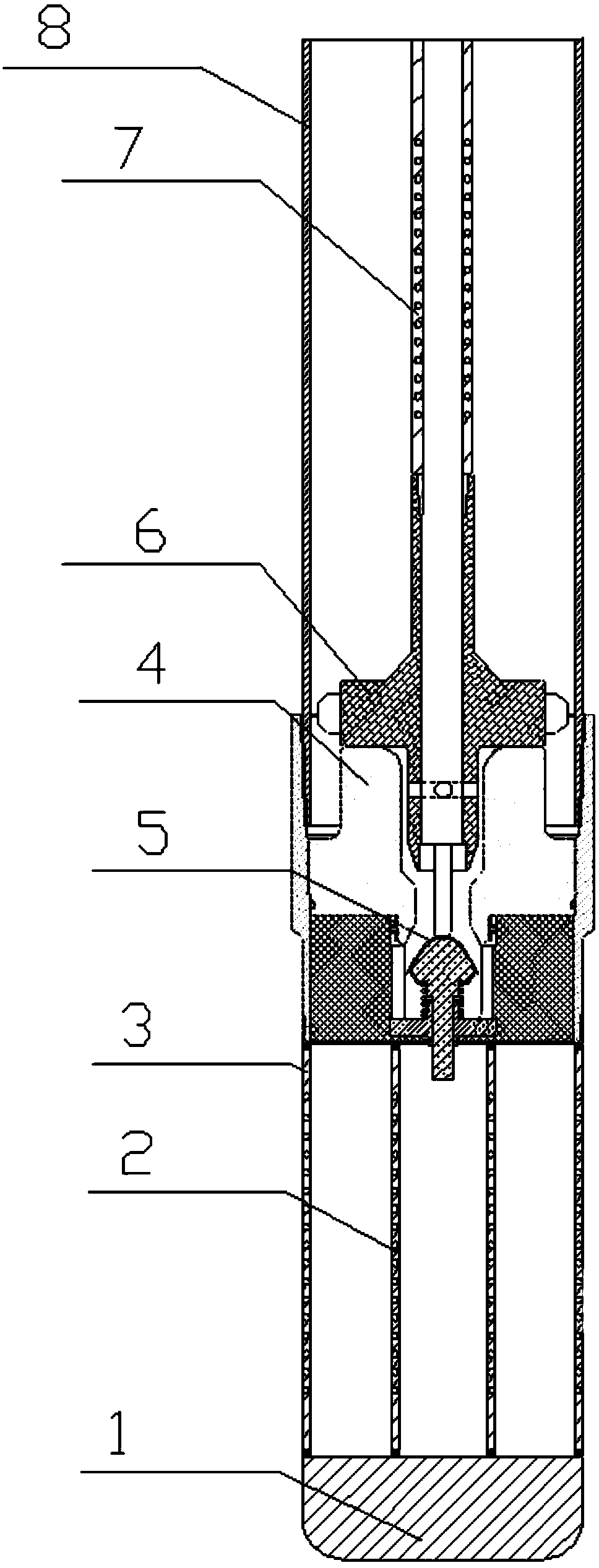

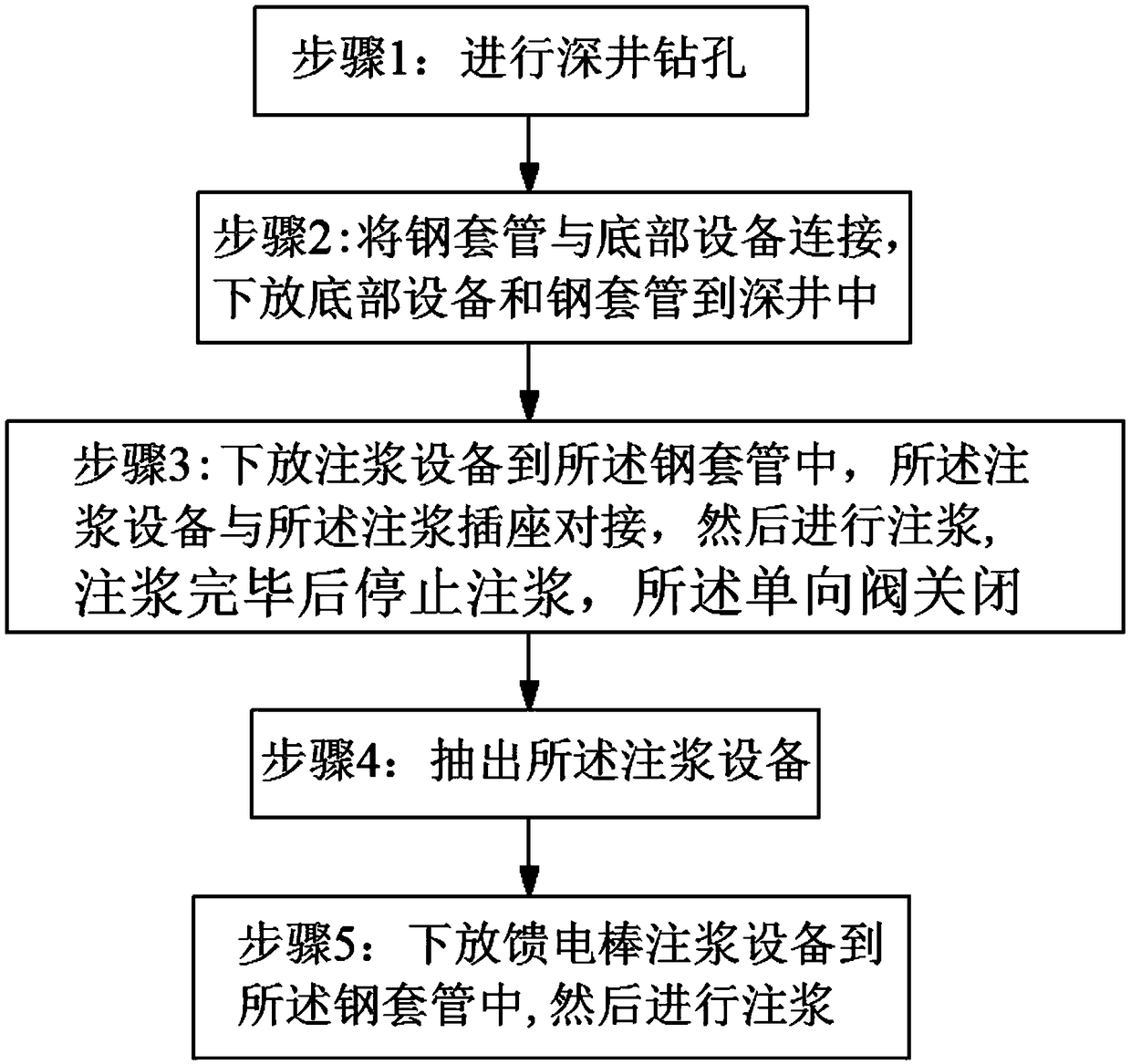

[0037] The invention provides a grouting system suitable for deep well grounding electrode feed rods, which can completely and quickly fill the coke slurry in the diffuse flow section after bottom grouting.

[0038] Please refer to the attached figure 1 , figure 1 It shows an embodiment of the bottom grouting system applicable to deep well ground electrode feeder rods of the present invention. This invention may, however, be embodied in many different forms and should not be construed as limited to the specific embodiments set forth herein.

[0039] Unless otherwise defined, terms (including technical and scientific terms) used herein should be understood to have the same meaning as commonly understood by those skilled in the art to which this invention belongs. Moreover, it is to be understood that the terms used herein should be understood to have a meaning consistent with the meaning in this specification and the relevant art, and should not be interpreted in an ideal or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com