Creep test loading device for non-metal anti-floating anchor

An anti-floating bolt and creep test technology, applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of time effect behavior of bolts, loss of anchoring force, etc. The effect of good performance and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

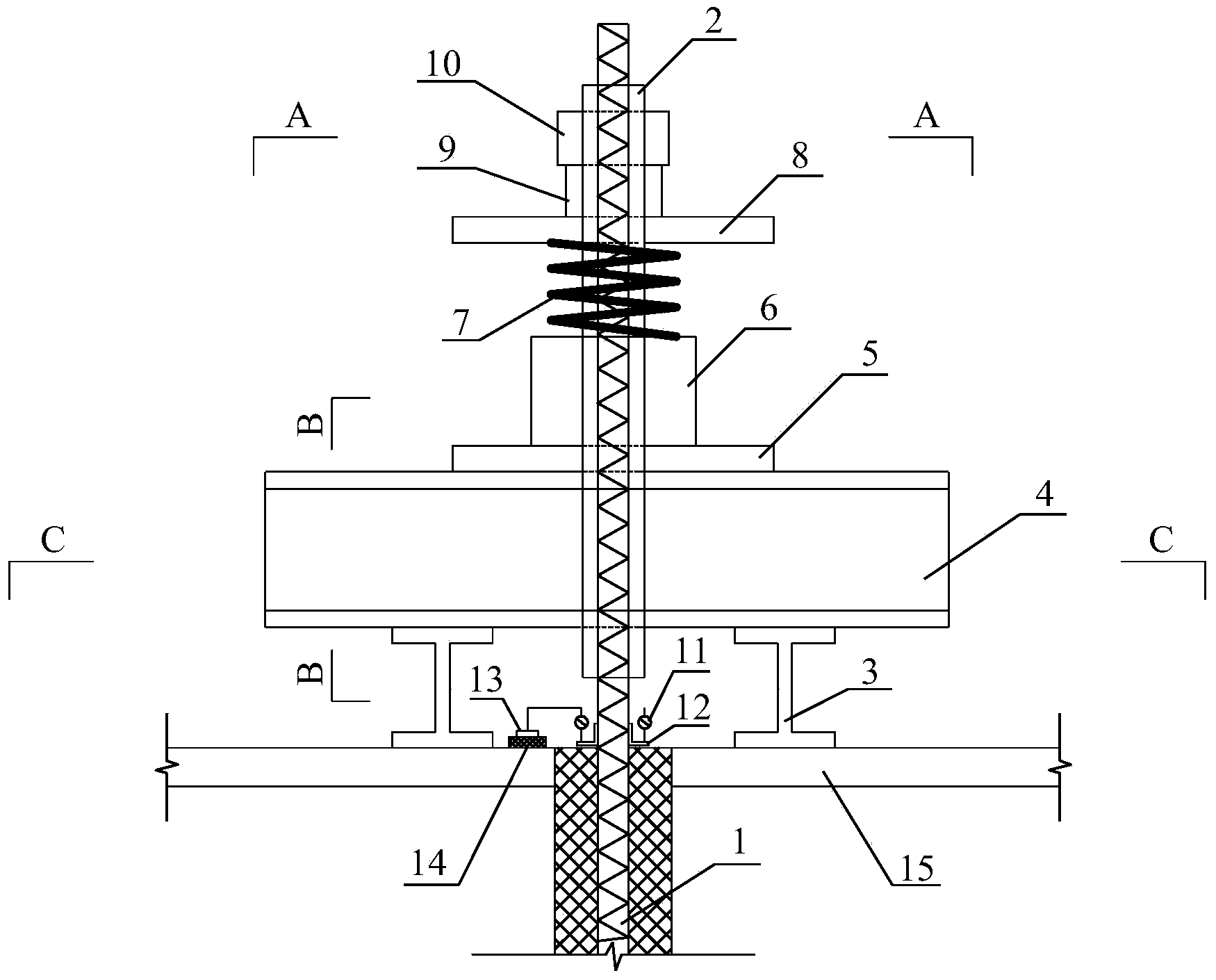

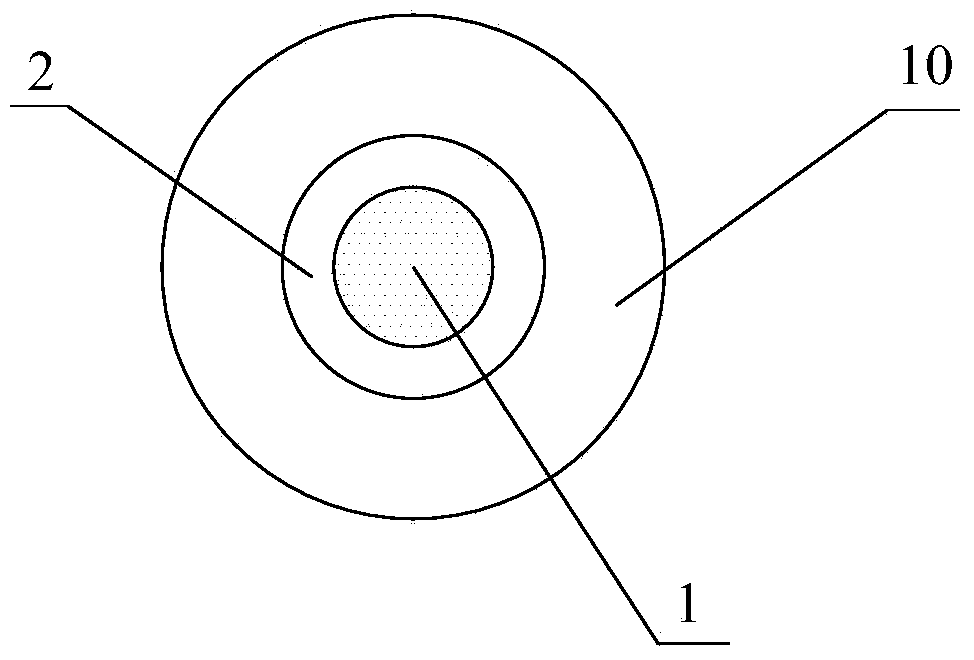

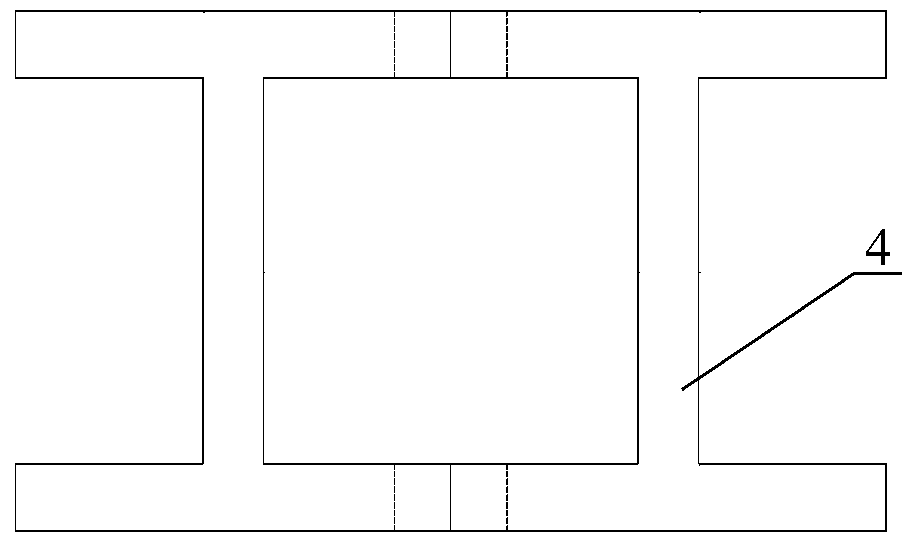

[0015] The main structure of this embodiment includes an anchor rod body 1, a steel sleeve 2, an I-beam 3, a reaction beam 4, a steel backing plate 5, a through-core jack 6, a spring 7, a steel plate 8, an anchor cable axial force gauge 9, Anchorage 10, dial indicator 11, L-shaped plexiglass 12, reference beam 13, concrete buttress 14 and concrete cushion 15; bolt body 1 is a glass fiber reinforced polymer (GFRP) full-threaded solid rod structure, which can Enhance the gripping force between the bolt body and the anchor body to provide sufficient anchoring friction; the inner diameter of the steel casing 2 is larger than the diameter of the GFRP bolt body 1, and the bolt body 1 and the steel casing 2 are filled with structural adhesive. They are closely bonded together to provide sufficient bonding force to prevent the damage of the material of the bolt body during the loading process. The length of the steel sleeve 2 is controlled by the design anchoring force; the webs of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com