Stainless steel casing pipe applied to local repair of pipeline

A technology for local repair and stainless steel pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., and can solve problems such as expensive and expensive repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

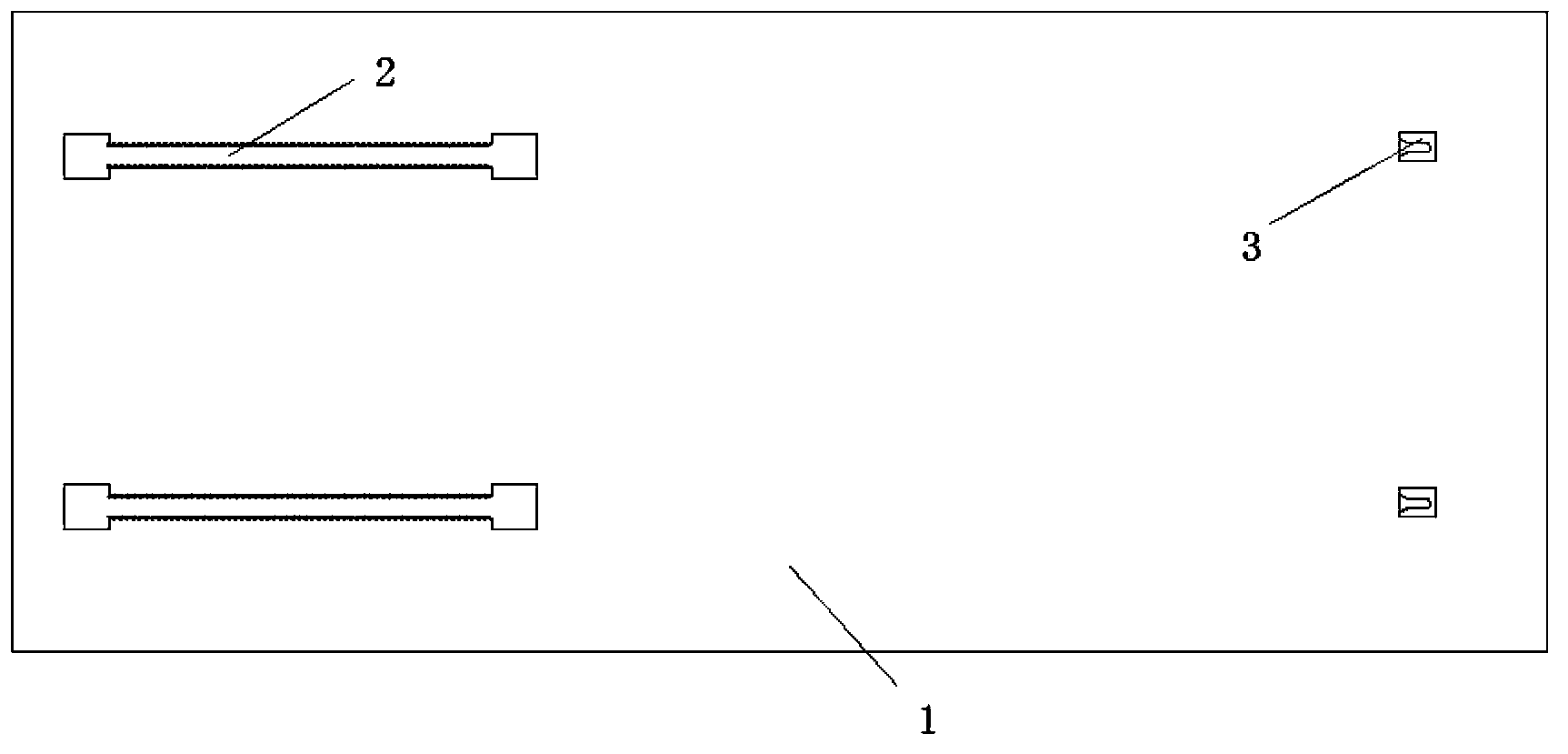

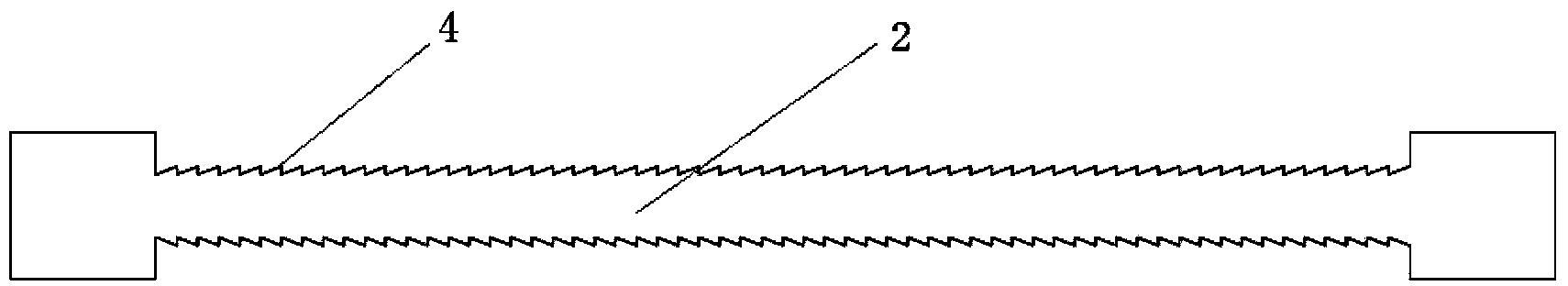

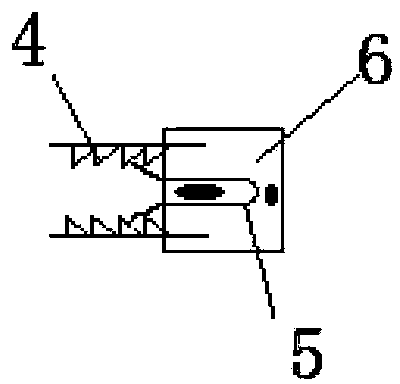

[0017] A kind of stainless steel sleeve used in partial repair of pipelines, including stainless steel tubes and auxiliary silicone rings outside the stainless steel tubes, refer to figure 1 , the stainless steel pipe is rolled by the first rectangular stainless steel plate 1, two slits 2 are opened in the direction parallel to the long side of the first rectangular stainless steel plate 1, and welded at the position corresponding to the slit 2 on the other side of the first rectangular stainless steel plate 1 Buckle 3, refer to figure 2 , the two ends of the gap 2 are (30-40)mm×(30-40)mm rectangles, the rectangle is provided with an inner opening and an outer opening, the inner opening is for snapping the buckle 3 into the gap 2, and the outer opening is for When the pipe exceeds the use range, the buckle 3 pops out from the gap 2, and the inner side of the gap 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com