Bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure and construction method thereof

A prefabricated shear force and plug-in technology, which is applied in the direction of building structure, floor slabs, building components, etc., can solve the problems of large construction impact, affecting construction progress, poor seismic performance, etc., to achieve improved bearing capacity and seismic ductility, and fast connection Convenience and the effect of improving shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

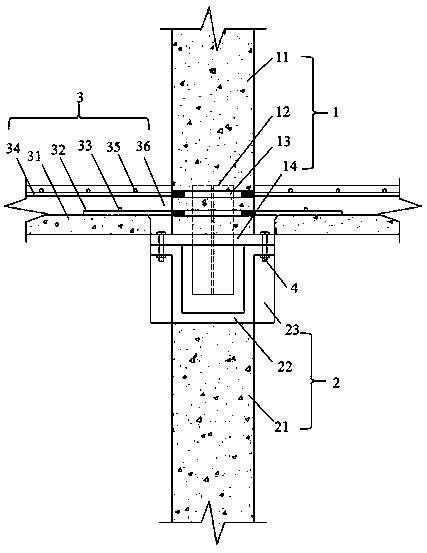

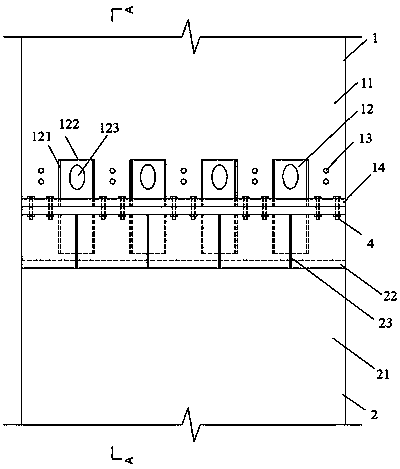

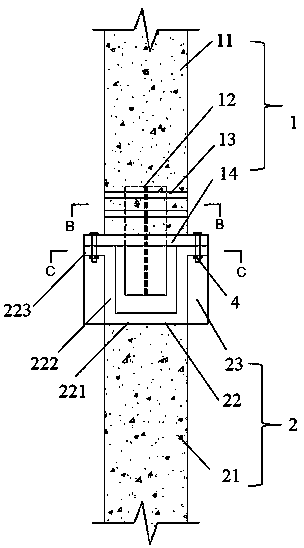

[0041] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0042] The connection structure between the upper and lower prefabricated shear walls and laminated slabs of the present invention is composed of an upper prefabricated shear wall 1, a lower prefabricated shear wall 2 and a floor 3, and the upper prefabricated shear wall 1 is composed of an upper prefabricated reinforced concrete wall 11. It consists of pre-embedded H-shaped steel 12, pre-embedded steel bar casing 13 and end plate 14. The pre-embedded H-shaped steel 12 is composed of two flanges 121 and a web 122, and the web 122 has H-shaped steel holes at the design position 123, the web 122 is located in the middle of the two flanges 121, forming an H shape, which can be welded or rolled, the surface of the web 122 is parallel to the surface of the upper pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com