Rapid pre-stressed anchor cable capable of being recycled and construction method thereof

A prestressed anchor cable, fast technology, applied in the direction of excavation, infrastructure engineering, construction, etc., can solve the problems of economic and safety discounts, affecting the construction period, high investment, etc., to achieve a simple and fast construction method, reduce working time, Safe and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

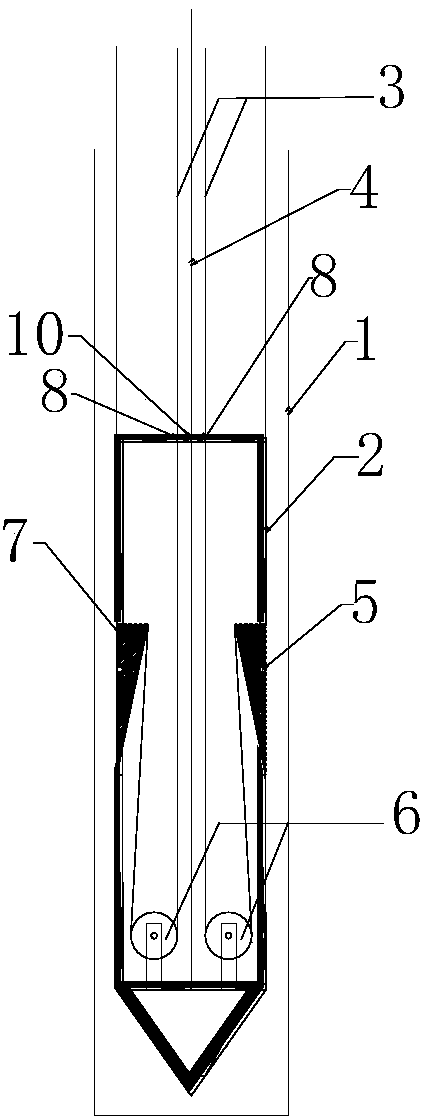

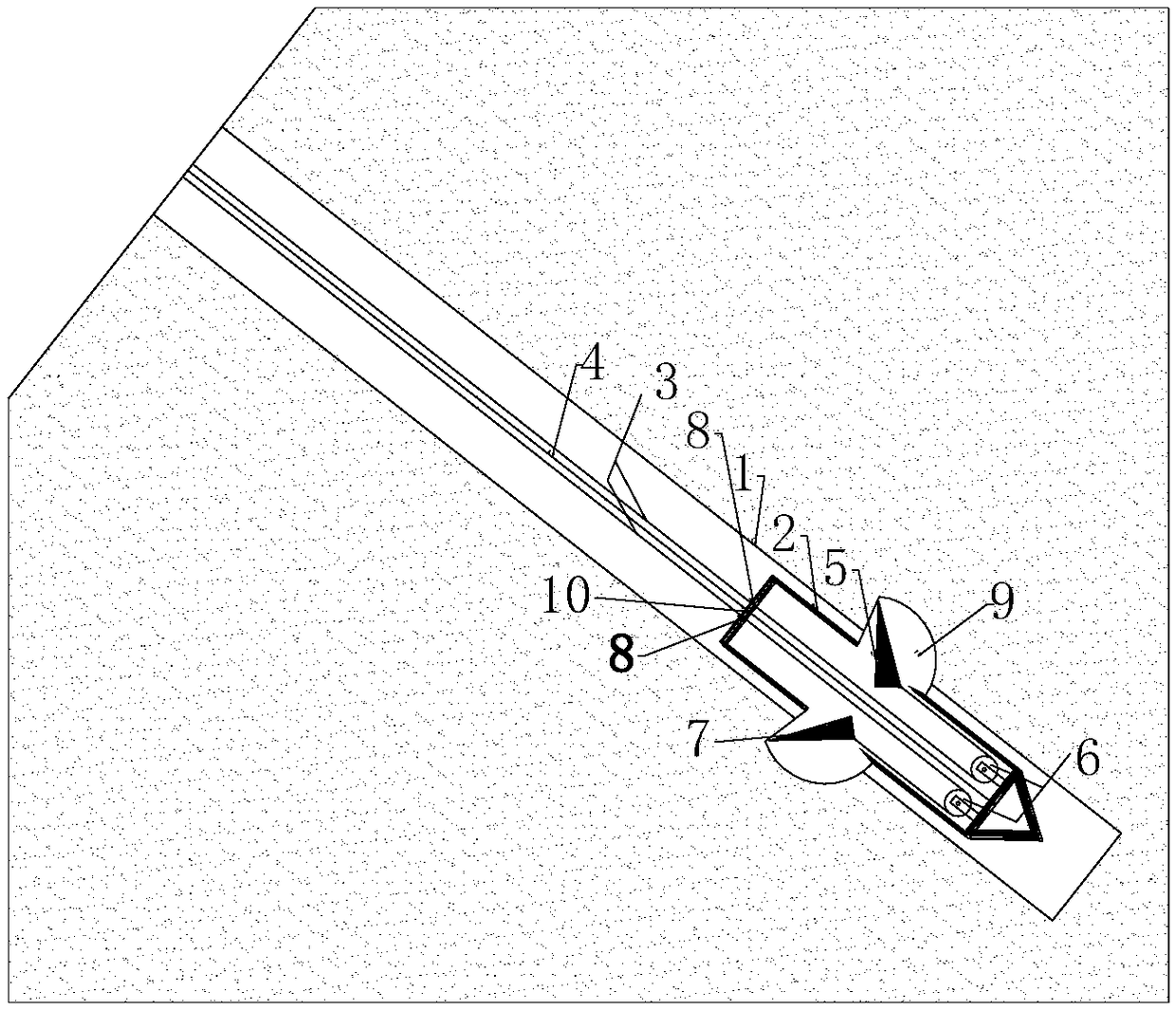

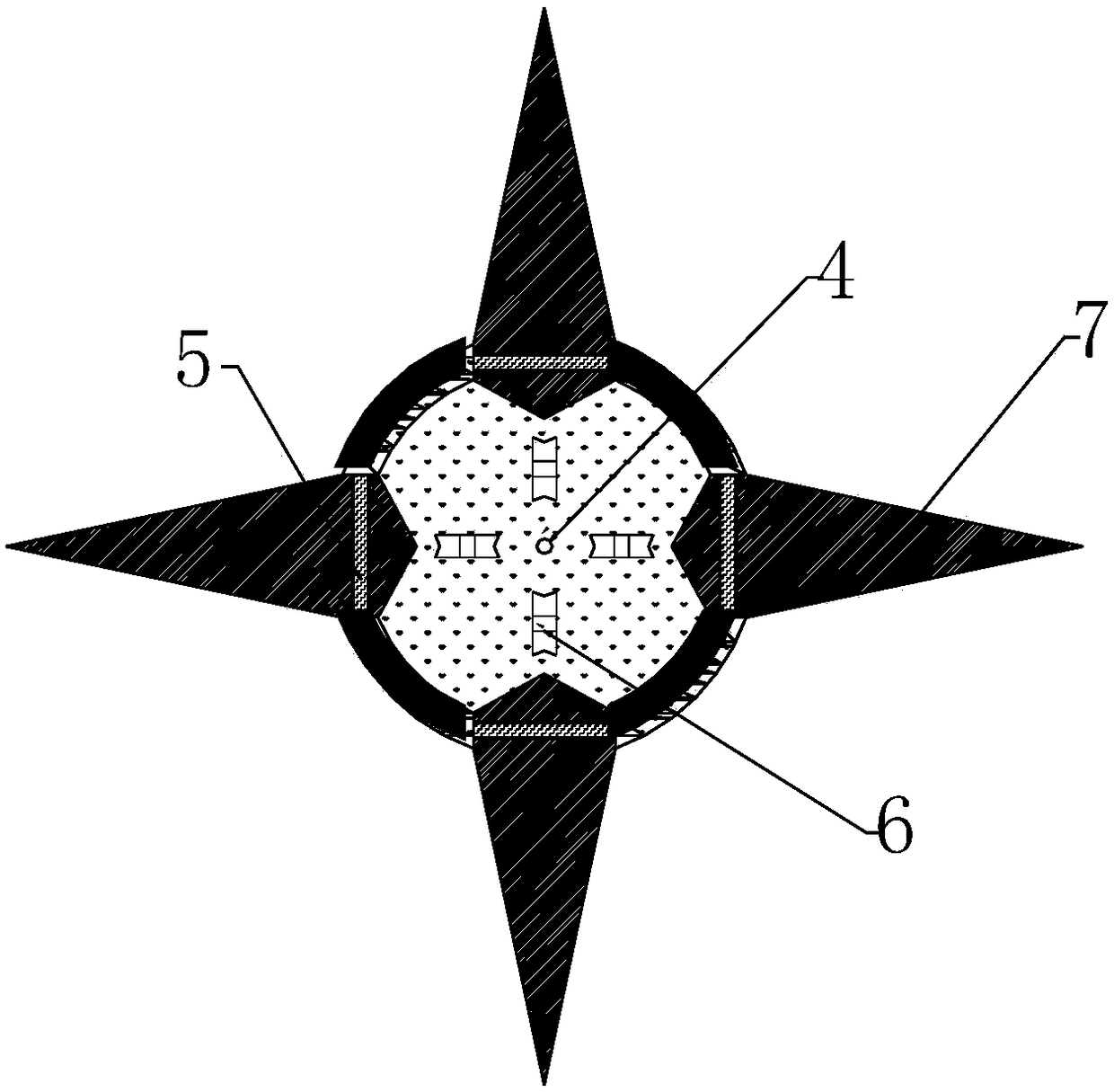

[0034] Such as Figure 1-7 As shown, a recoverable fast prestressed anchor cable includes a steel casing 2, a non-stressed steel strand 4 and several symmetrically distributed enlarged structures. The bottom of the steel casing 2 is provided with a conical head, and the side wall is provided with A number of symmetrically distributed openings (one-to-one correspondence between the enlarged structure and the opening), the upper end is provided with a cover, and the cover is provided with a reserved hole 8 for stressed steel strands and a reserved hole 10 for non-stressed steel strands. The enlarged structure includes a fixed pin 5, a fixed pulley 6, an enlarged head 7 and a stressed steel strand 3, the fixed pin 5 and the enlarged head 7 are arranged in the opening of the side wall of the steel casing 2, and the two ends of the fixed pin 5 are connected to the steel casing 2 fixedly connected, the expansion head 7 is rotationally connected with the steel sleeve 2 through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com