Horizontal well spacing method based on sand body structure

A technology of sand body structure and horizontal well, which is applied in the directions of wellbore/well components, production fluid, earthwork drilling, etc., can solve the problem of less consideration in geological aspects, and achieves the improvement of single well control reserves, reduction of economic costs, and high efficiency. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

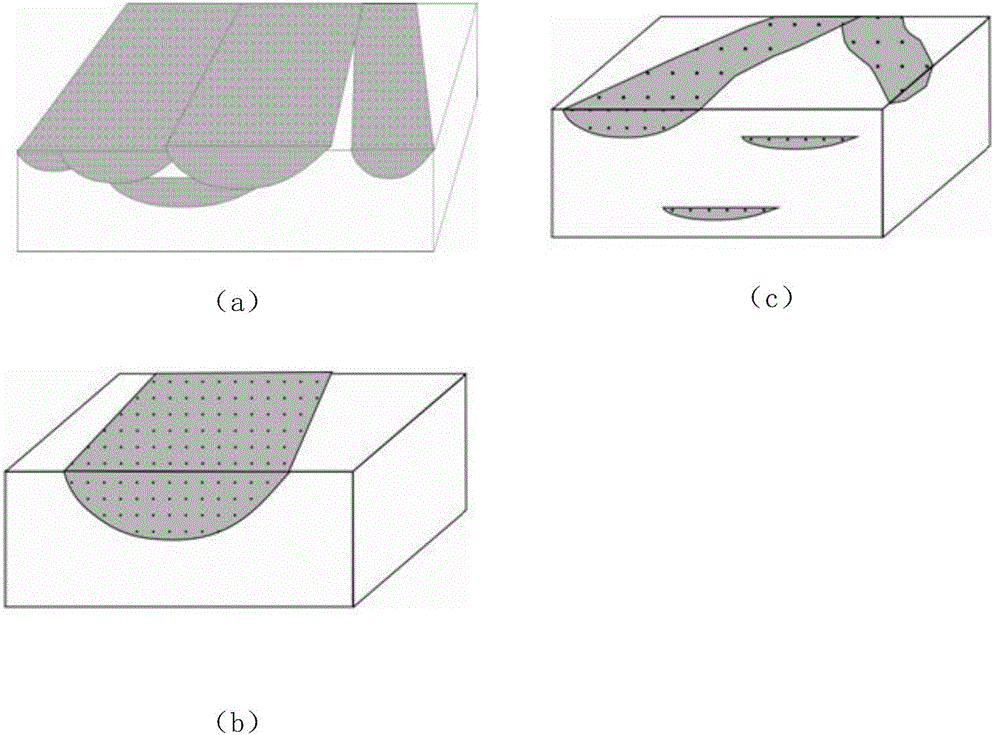

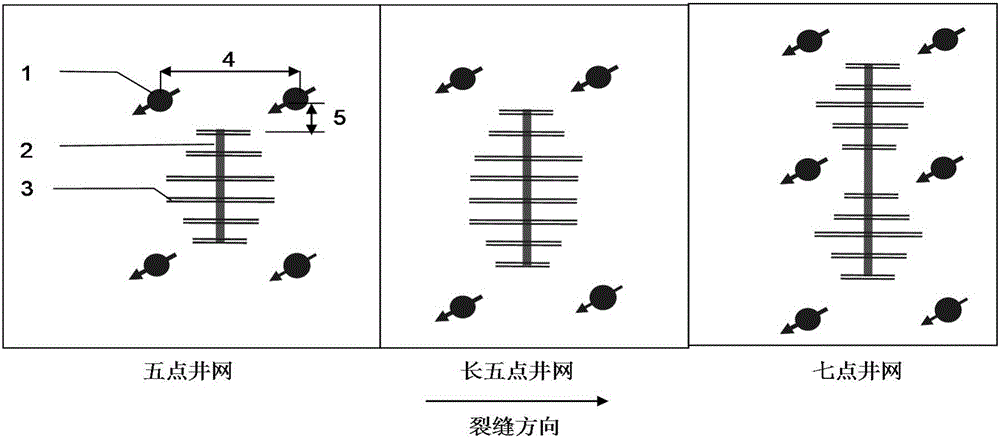

[0028] The invention provides a horizontal well layout method based on the sand body structure. Its objectives and basic principles are as follows: First, the integration of geological and oil reservoirs, the deployment of well pattern fully considers geological characteristics, comprehensively produces oil reservoirs, and improves the drilling experience of horizontal wells. The second is to reduce economic costs, adapt to standardized production, and adopt regular well patterns; the third is to facilitate the better use of artificial fracture seepage capacity, establish an effective displacement system, and meet the requirements of long-term stable water injection and energy supplementation.

[0029] The steps of the present invention include:

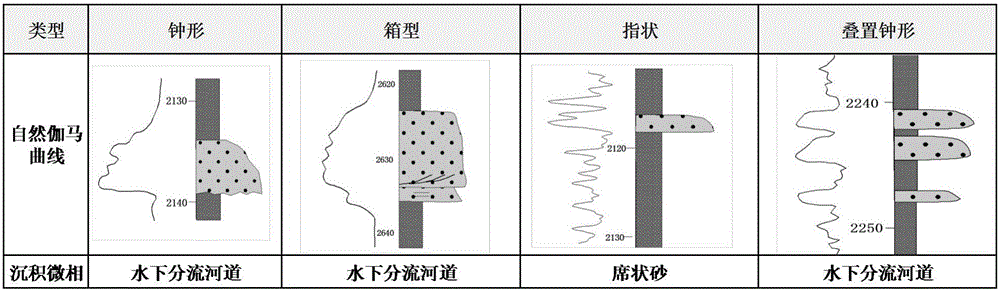

[0030] (1) Select the natural gamma ray curve of the required research interval in the target area. According to the shape of the curve and the thickness of the sand layer, the sand body structure is divided into four types. A bell-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com