Straight hole drilling method for drilling machine

A drilling rig, straight hole technology, applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of uneven force on the drill bit, and it is difficult for the drill to reach the designated position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

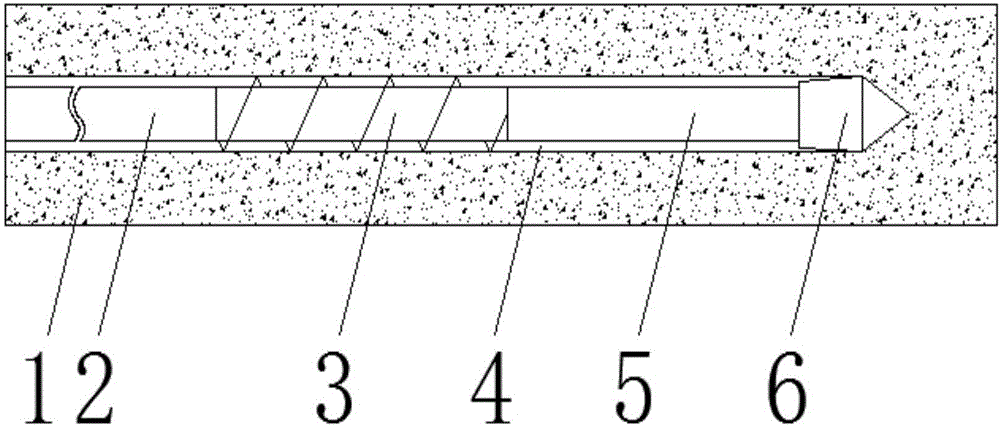

[0015] Such as figure 1 As shown, the drilling rig of the present invention drills a straight hole drilling method, utilizes drill bit 6 and drill rod 2 to drill, and described drill rod 2 comprises circular drill rod 5 and threaded drill rod 3, threaded drill rod 3 and common circular Drill rod 2 is identical with drill rod 5 internal diameters, is provided with the connecting piece that connects thread by internal thread or two ends is connected and fastened, and threaded drill rod 3 external diameters are identical with drill bit 6, and both external diameters are larger than circular drill rod 5.

[0016] The threaded drill rod 3 is composed of a hollow cylinder and an external thread, and is made of high-strength steel with high bending strength, which can effectively prevent the drill bit from bending when the force is uneven. The thread on the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com