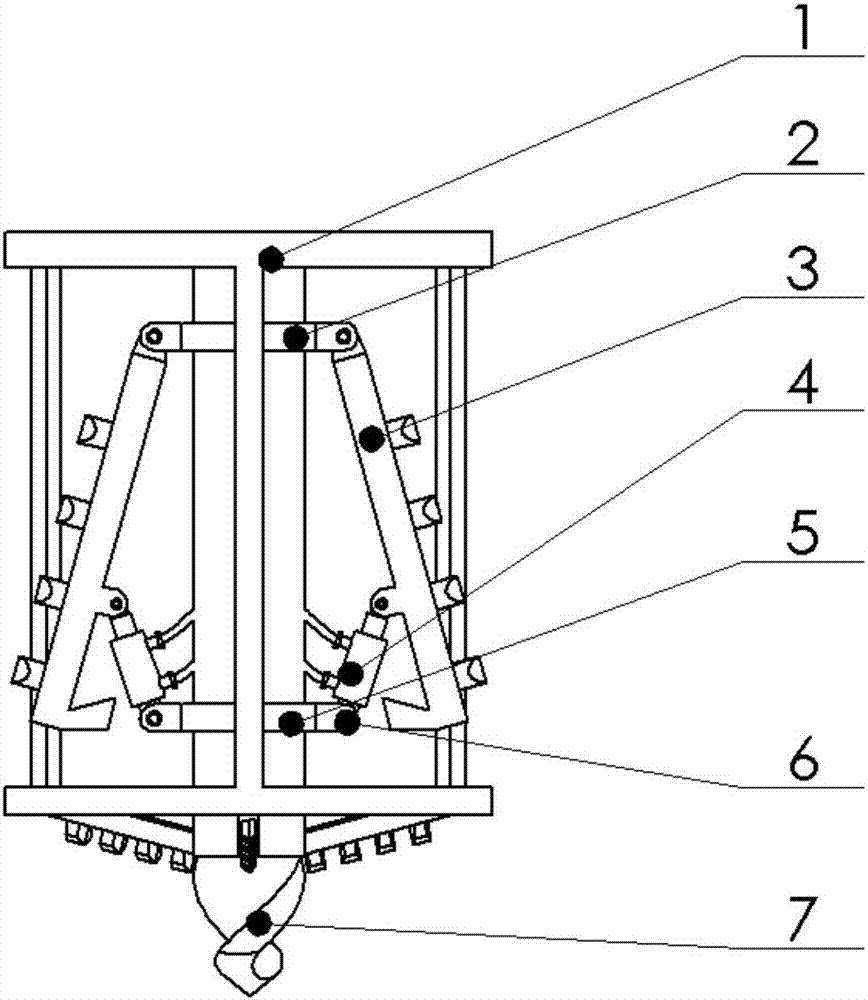

Drill bit device for variable diameter drilling and construction method

A construction method and drill bit technology, applied in the direction of drill bits, fluid pressure actuators, drilling equipment, etc., can solve the problems of high drilling resistance, drill sticking, and low drilling efficiency, so as to reduce drilling resistance and save construction time , The effect of reducing the risk of stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

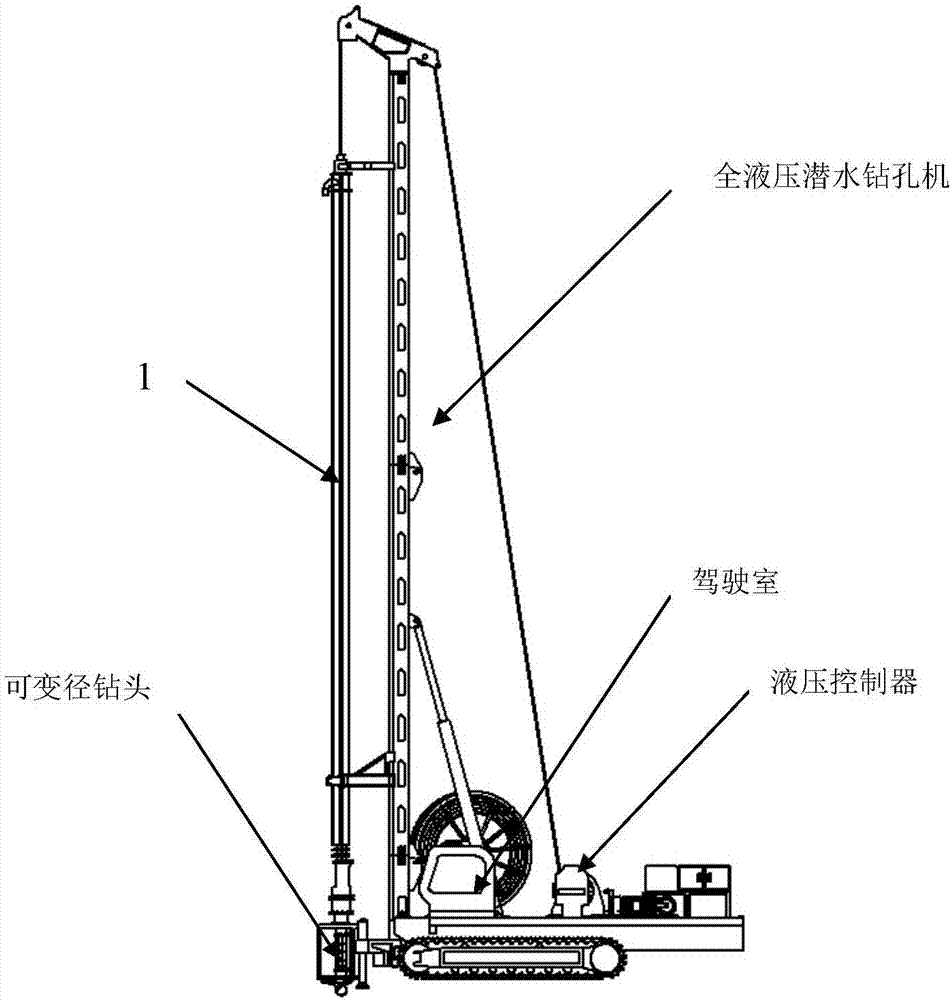

[0028] Such as figure 2 Shown, described variable-diameter drill bit device is fixed on the drilling rod ( diagram 2-1 ), the oil cylinder oil pipe of the variable diameter drill bit device is connected to the hydraulic controller of the fully hydraulic submersible pile drilling machine through the central connection of the drill pipe, and the hydraulic controller is connected with the main engine in the cab, thus forming a controllable loop. When the operator manipulates the handle with a scale to the designated position, the controller receives instructions and controls the hydraulic system to output (or reduce) pressure to the cylinder to make the cylinder piston extend (or shorten) to control the opening angle of the movable knife row, and then through the cylinder The feedback signal from the upstroke sensing device adjusts the cylinder to output a steady pressure to achieve the predetermined diameter.

[0029] Using the construction method of the above-mentioned varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com