Autonomous seabed deep stratum drilling robot

A robot and formation technology, applied in the field of robotics, can solve the problems of increasing the volume and weight of the robot, large formation damage, and lack of autonomous drilling capabilities, etc., to avoid motor sealing problems, reduce drilling resistance, and wide speed range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

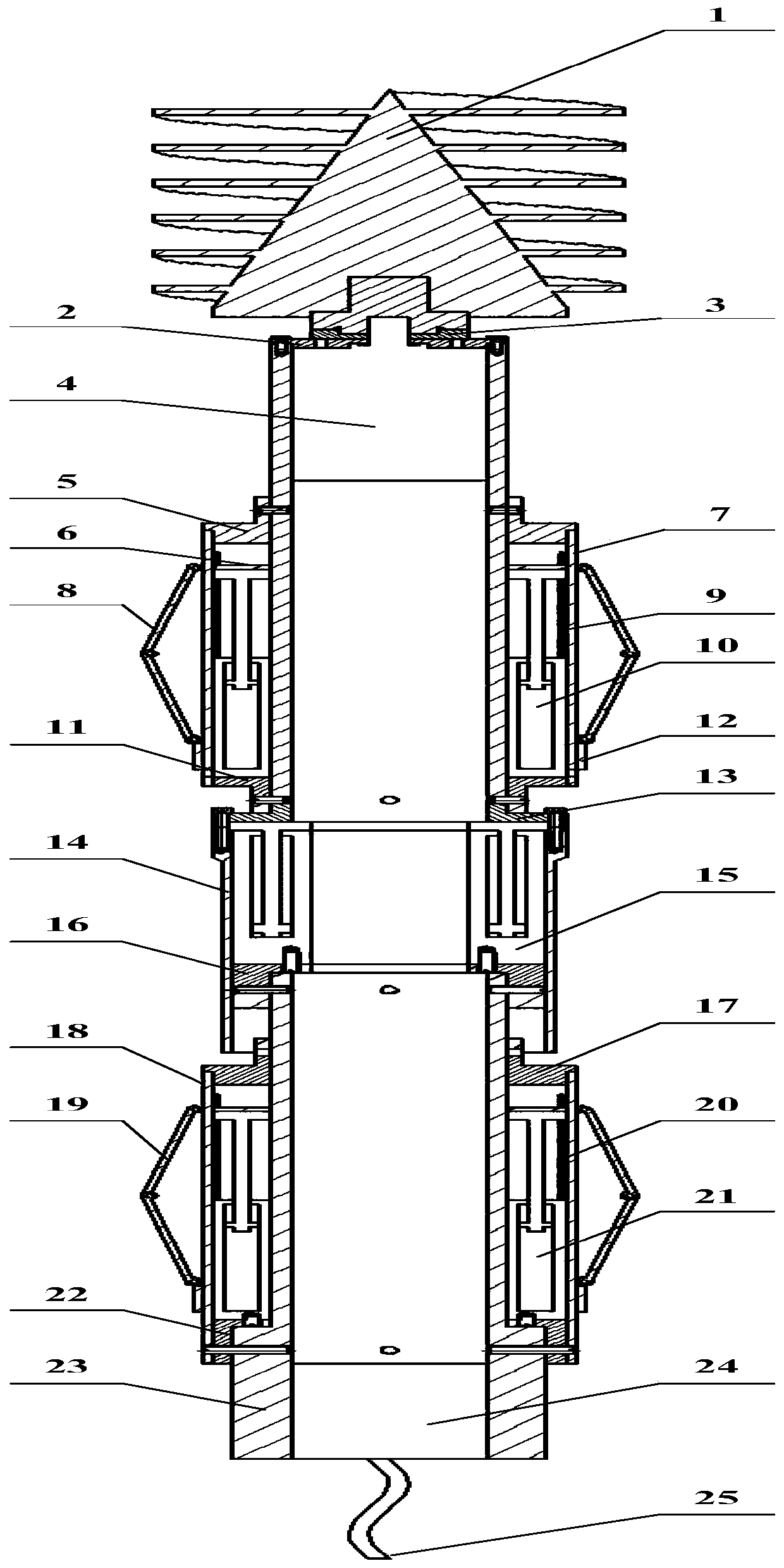

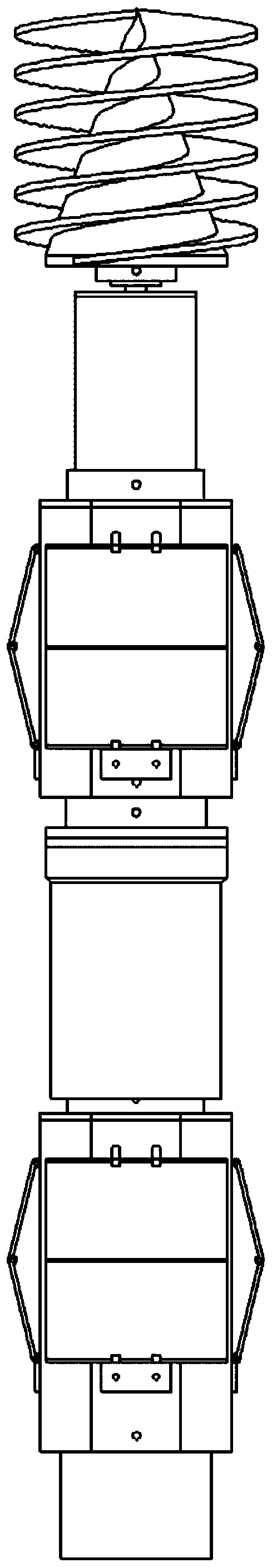

[0031] Such as figure 1 , the present invention is a multi-section structure as a whole, which successively includes a head drilling mechanism, a front support body section, a propulsion body section, a rear support body section and a tail control cabin from top to bottom.

[0032] The head drilling mechanism includes a helical drill bit 1, the tail end of the drill bit 1 is connected to a hydraulic motor through an output shaft, the hydraulic motor is installed in the power cabin 4, the main body of the drill bit 1 is a conical structure, and an equal-pitch helical chip guide is provided outside. A sealing ring 3 is arranged between the drill bit 1 and the power cabin 4, and a power cabin flange 2 is arranged at the front end of the power cabin 4.

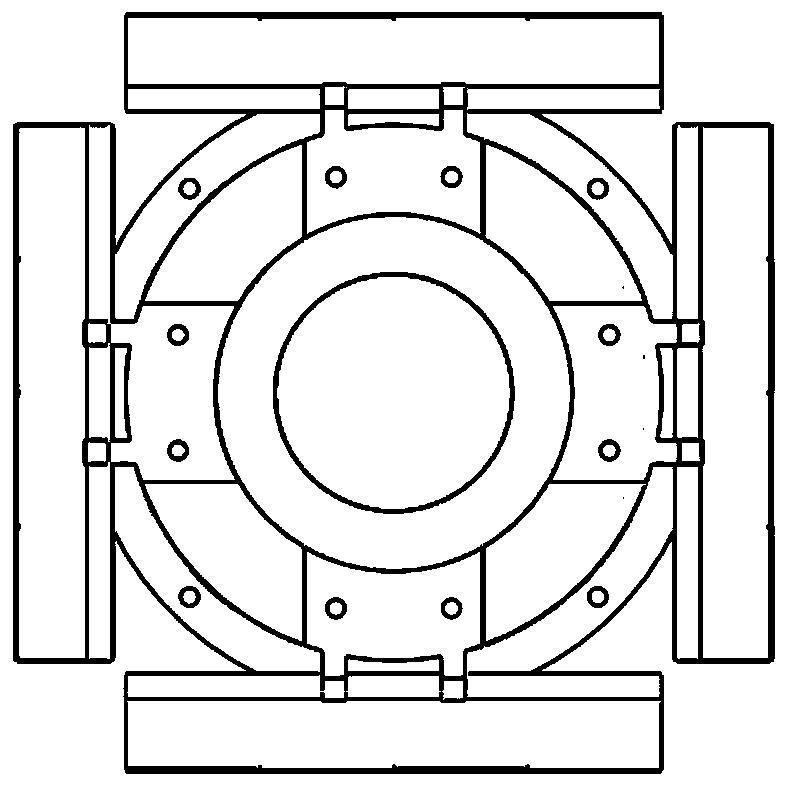

[0033] Both the front support body section an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com