Ultra-deep drilling bit apparatus for high tailing dam

A tailings dam and drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as sticking, and achieve the effects of low cost, reduced wear, and prevention of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

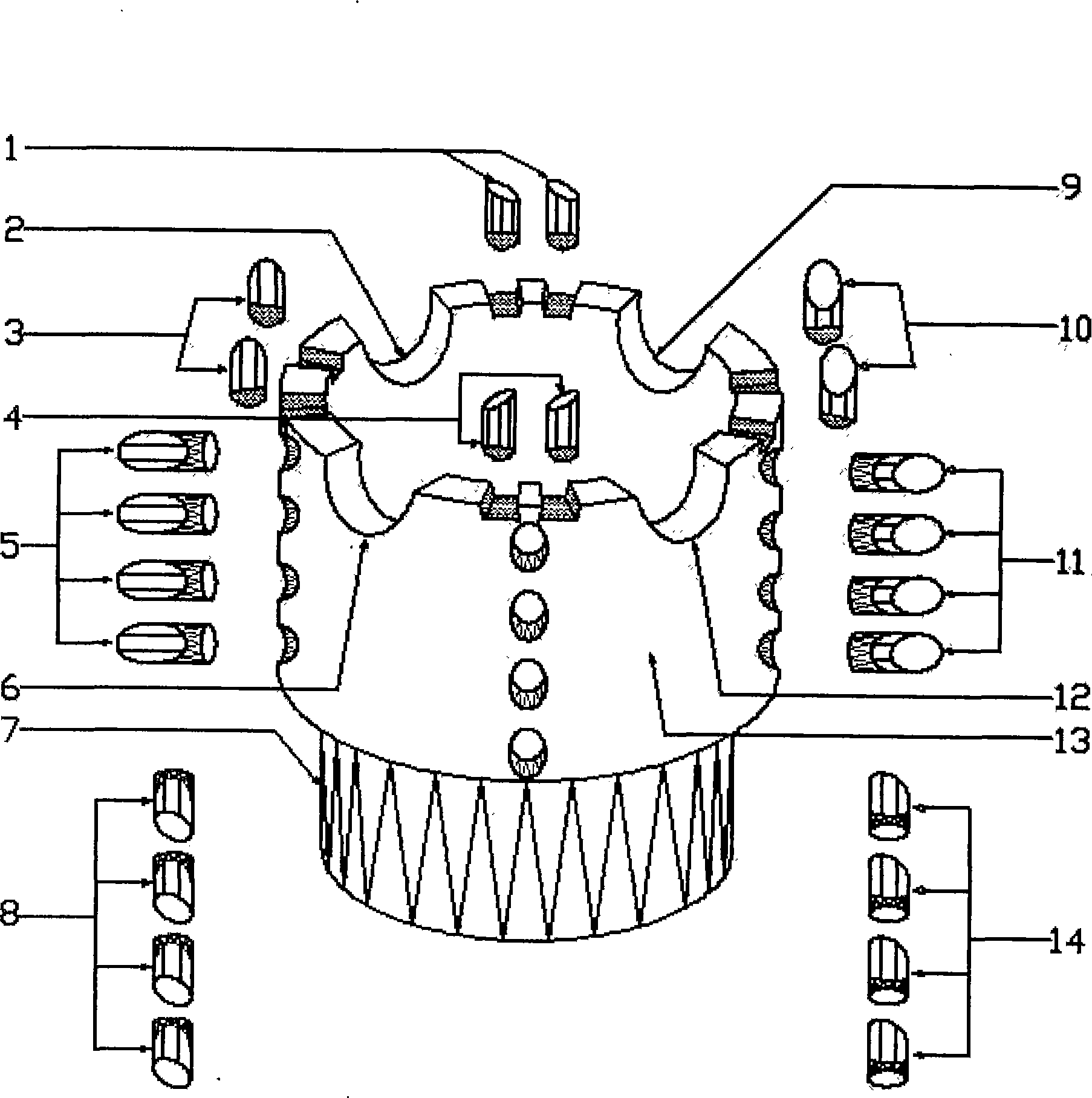

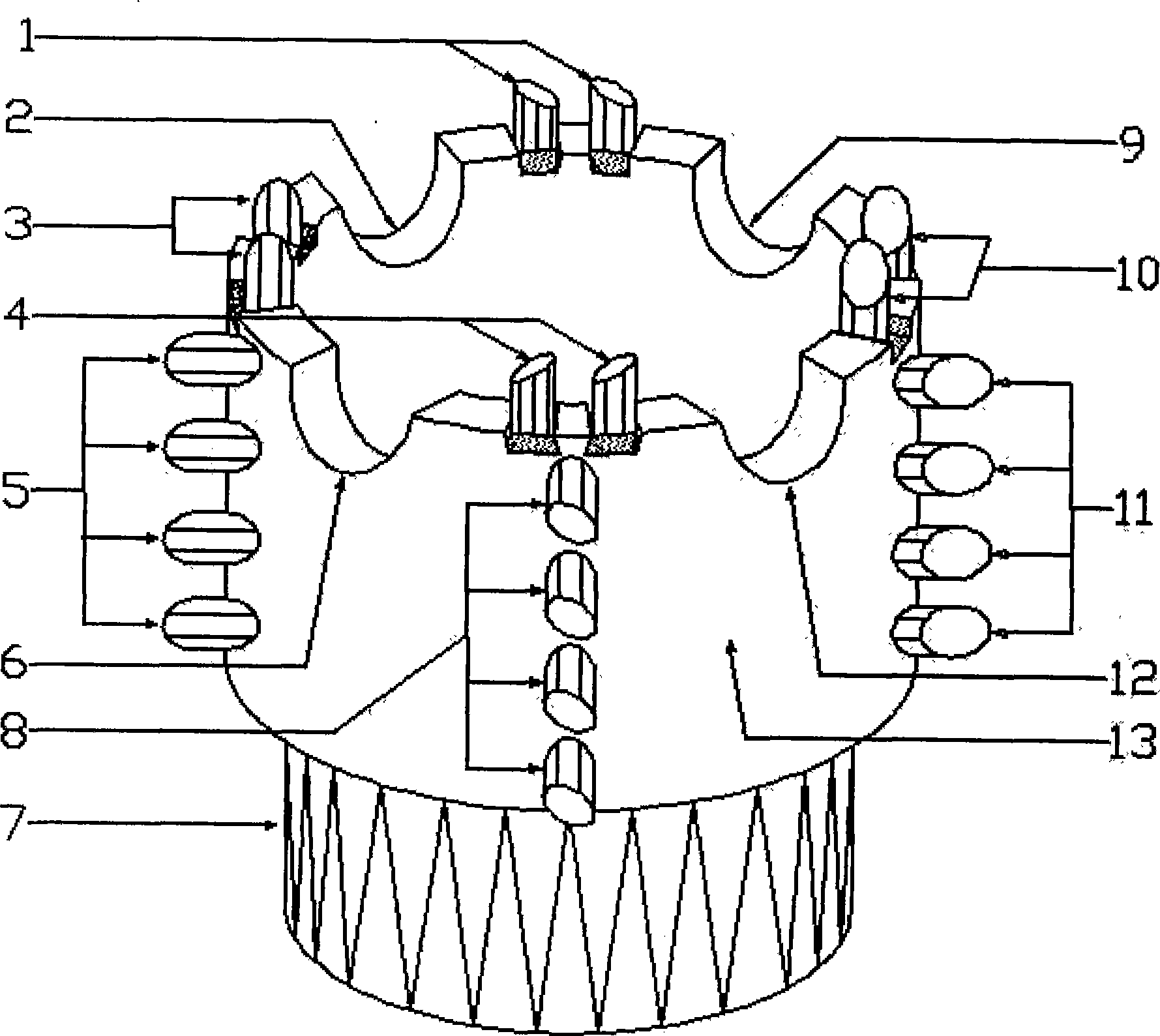

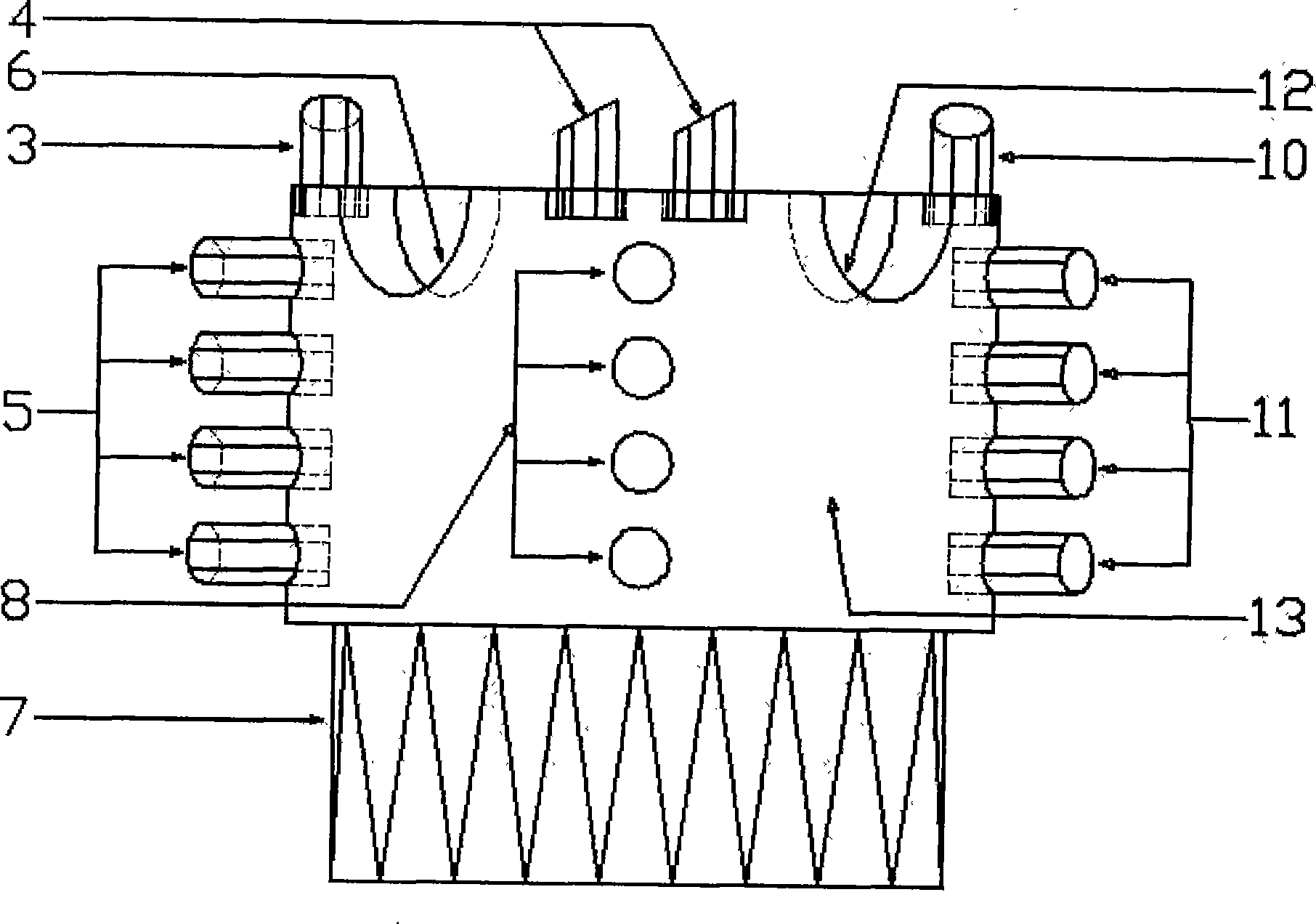

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] according to figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the device includes cemented carbide 1, 3, 4, 10, surface-mounted alloys 5, 8, 11, 14, nozzles 2, 6, 9, 12, carcass 13, and threaded buckle 7. Its connections and functions are:

[0027] A high tailings dam ultra-deep drilling drill bit device, which includes the first, second, third, fourth cemented carbide 1, 3, 4, 10, the first, second, third, and fourth surface-mounted alloy 5 , 8, 11, 14, the first, the second, the third, the fourth nozzle 2, 6, 9, 12, threaded button 7, it is characterized in that: on the bottom lip surface of the carcass 13, the first, The second, third, and fourth groups of V-shaped grooves, the dimensions of the first, second, third, and fourth groups of V-shaped grooves should be the same as those of the first, second, third, and fourth groups of cemente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com