Long-life ridge type polycrystalline diamond compact

A technology of polycrystalline diamond and composite sheet, which is applied to drilling equipment, earthwork drilling, drill bits, etc. It can solve the problem of low service life of ridge-shaped diamond composite sheet, improve rock breaking efficiency, increase ROP, and increase The effect of impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

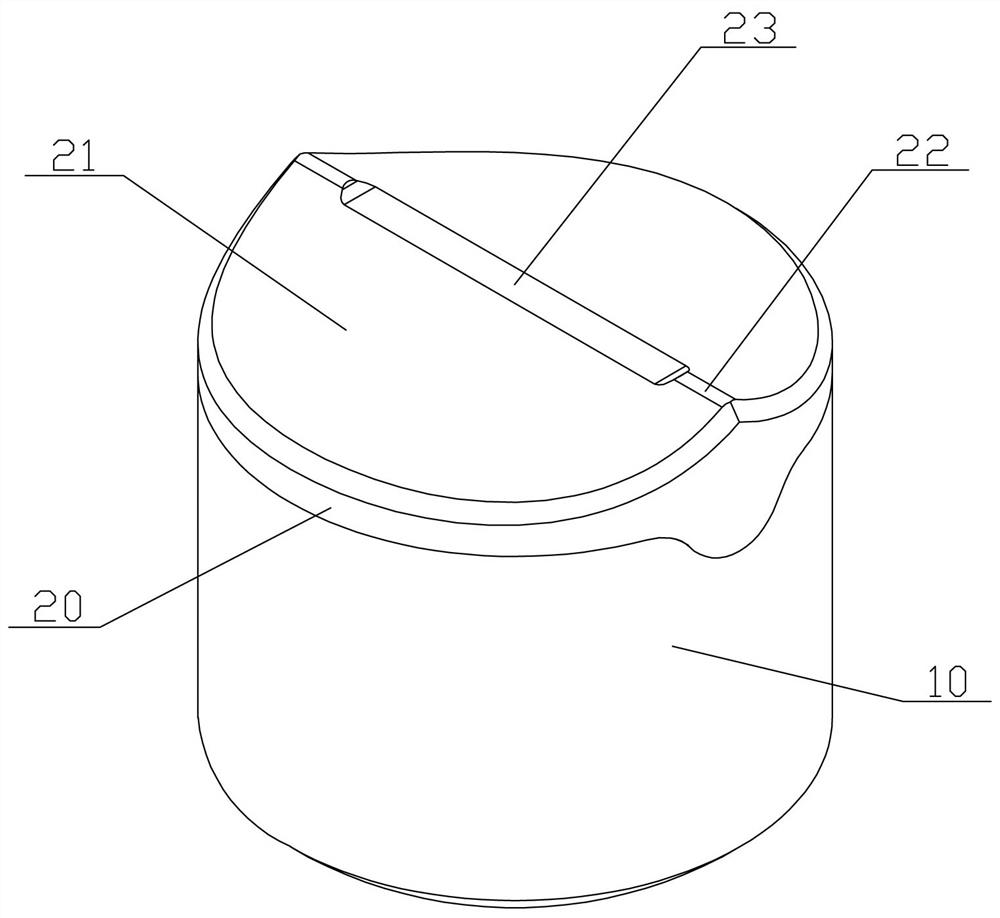

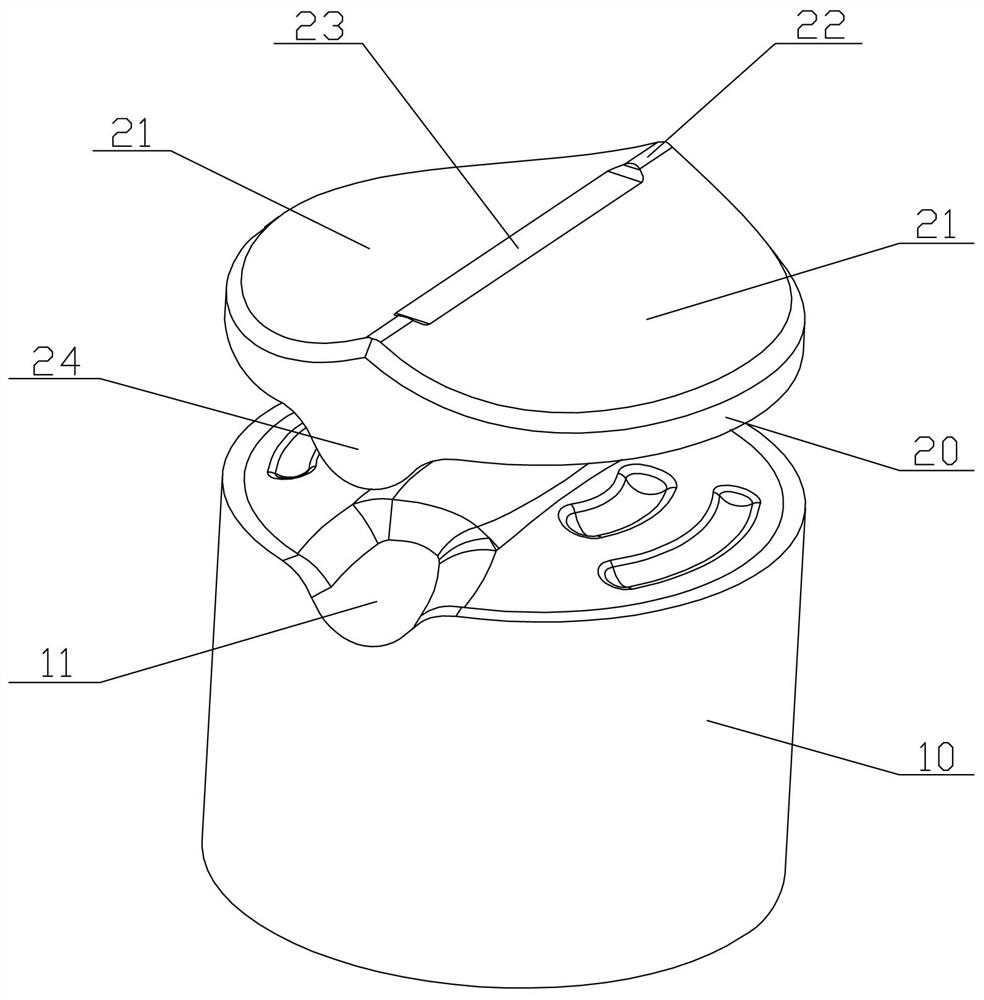

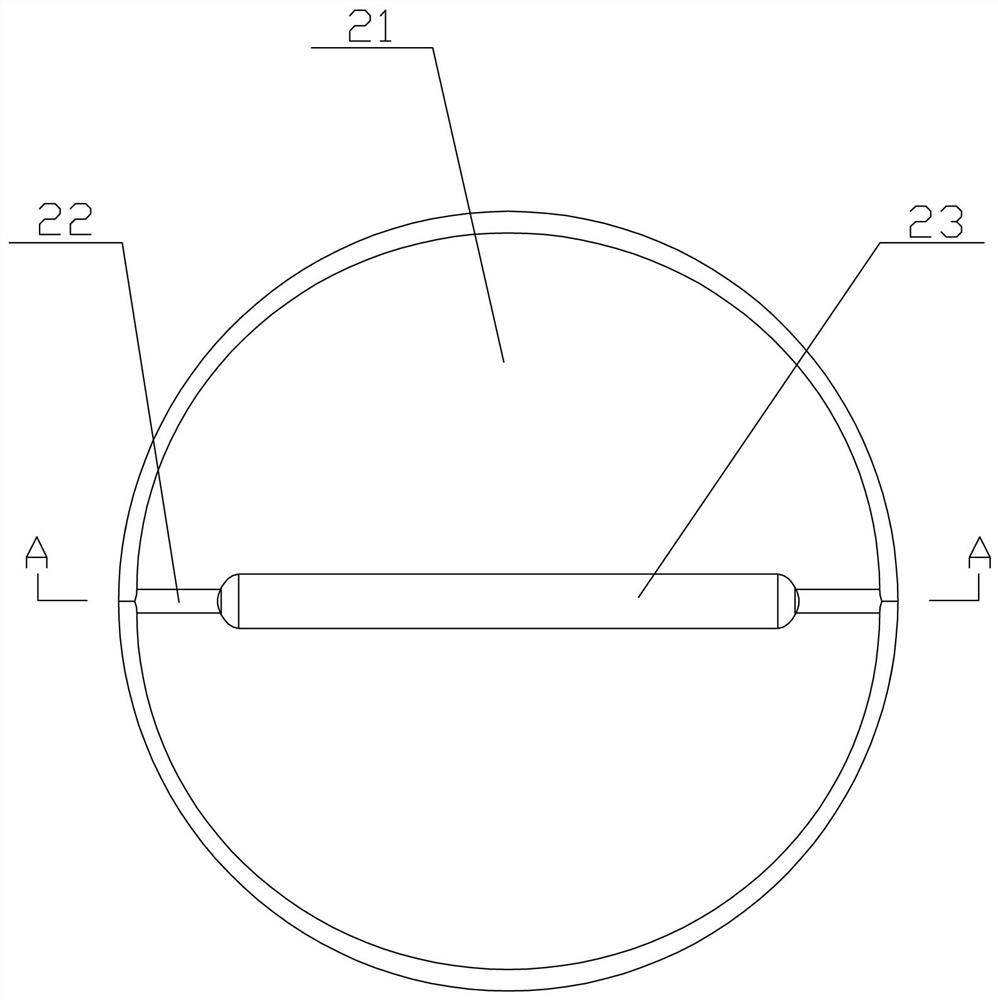

[0039] refer to Figure 5 and Image 6 The polycrystalline diamond compact of this embodiment also includes a cemented carbide substrate 10 and a polycrystalline diamond layer 20 fixed on the cemented carbide substrate. The polycrystalline diamond compact has a diameter of 15.88mm and a total height of 13.20mm. The end face of the polycrystalline diamond layer 20 of the present embodiment is made up of three tangent planes 21 and a triangular plane 22, wherein, three tangent planes 21 are bevel structure, and the angle of three bevels and end face is 10 °, and triangular plane 22 is a side An equilateral triangle with a length of 8mm.

[0040] refer to Figure 5, every two adjacent cut surfaces 21 are transitionally connected by a raised ridge 211, and the top of the raised ridge 211 is a rounded corner of 2.00 mm; each cut surface 21 is also connected with a triangular plane 22 by a raised ridge 211, the raised The top of the ridge 211 is also rounded at 2.00 mm. Of cours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com