Coal-mine broken-soft-coal-seam flexible internal control rotary directional drilling system and method

A rotary directional and directional system technology, used in directional drilling, mining equipment, earth-moving drilling, etc., can solve the problems of large powder production in broken and soft coal seams, easily induced in-hole accidents, poor deflection effect, etc. Improve the effect of gas drainage, reduce the blind spot of gas drainage, and ensure the effect of smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

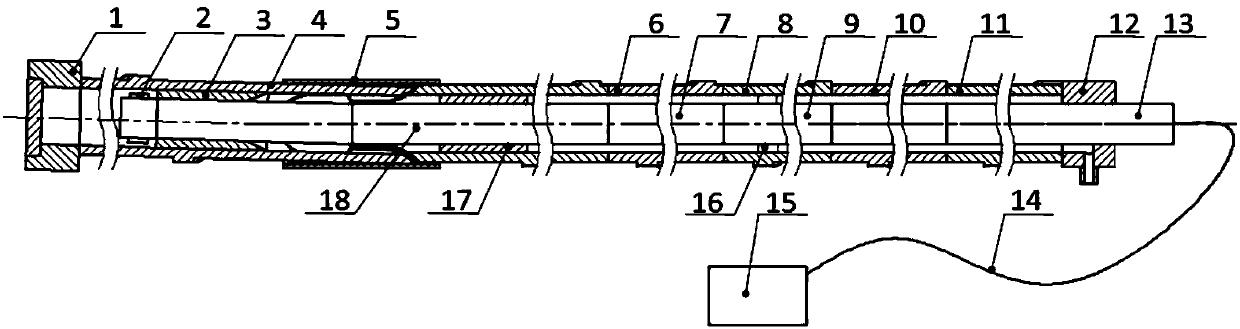

[0040] see Figure 1 to Figure 5 , shows the flexible internal control rotary directional drilling system and the drilling method of the present invention in the broken soft coal seam under the coal mine.

[0041] The flexible internal control rotary directional drilling system for broken and soft coal seams under the coal mine includes a flexible internal control rotary directional drilling tool, an orientation system, an auger rod 11, an openable and closed drill bit 1 and a double power head drilling rig. The directional drilling tool is located between the auger rod 11 and the openable and closable drill bit 1 to realize rotary directional drilling. The directional system runs through the auger rod 11 to measure the drilling trajectory. head and small power head to provide drilling power.

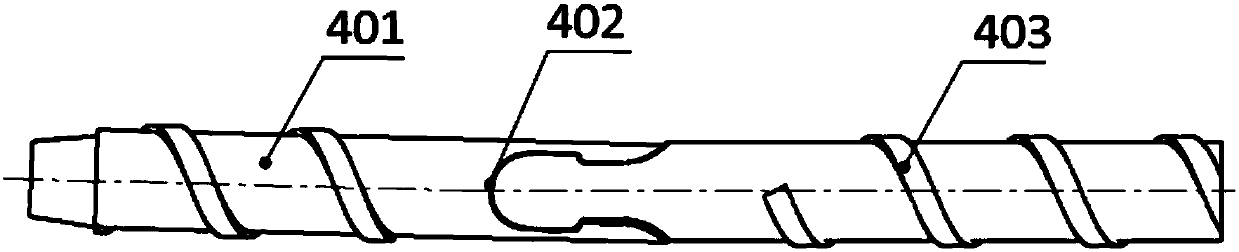

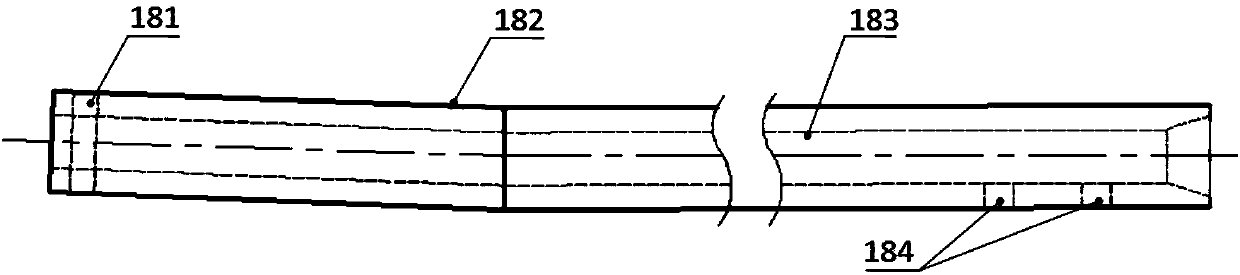

[0042] see figure 1 , the flexible internal control rotary directional drilling tool is composed of a flexible outer tube 4, a curved mandrel 18, a front bearing group 3, a rear beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com