Multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling and drilling method

An open, soft coal seam technology, applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as affecting the gas extraction range and extraction efficiency, low drilling efficiency, and easy blockage of drilling holes. Achieve the effect of preventing heat accumulation, improving drilling efficiency and increasing drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

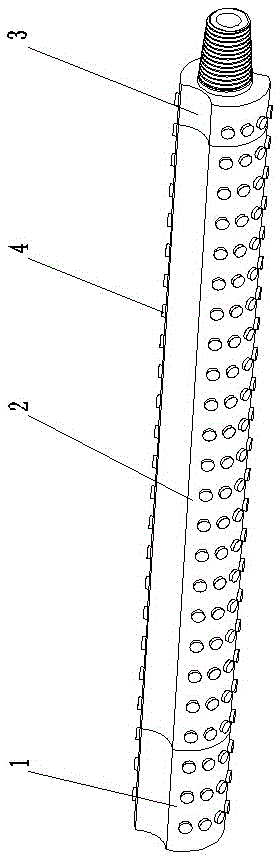

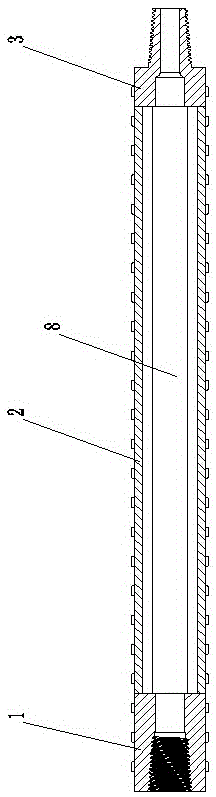

[0036] Embodiment one: if Figure 1 ~ Figure 3As shown, the soft coal seam of the present invention is drilled into a multi-wing concave open type bionic resistance reducing drill pipe, including a multi-wing concave open type concave connector 1, a multi-wing concave open hollow rod body 2 and a multi-wing concave The open convex connector 3, the multi-wing concave open concave connector 1, the multi-wing concave open hollow rod body 2 and the multi-wing concave open convex connector 3 are coaxially arranged, and the multi-wing concave open concave The connector 1 and the multi-wing concave open convex connector 3 are respectively connected to the two ends of the multi-wing concave open hollow rod body 2, the multi-wing concave open concave connector 1, the multi-wing concave open hollow rod body 2 A fluid channel 8 communicating with the multi-wing inner concave open convex connector 3 is axially provided; the multi-wing inner concave open concave connector 1, the multi-wing...

Embodiment 2

[0054] Embodiment two: if Figure 4 ~ Figure 6 As shown, the difference from the first embodiment is that there are three arc-shaped wings 5 designed for the cross-section of the drill rod, and the usage method of the second embodiment is the same as that of the first embodiment.

Embodiment 3

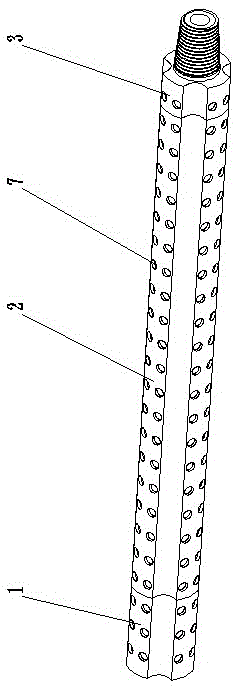

[0055] Embodiment three: as Figure 7 ~ Figure 9 As shown, the difference from Embodiment 1 and Embodiment 2 is that the cross-section of the drill rod is designed with four arc wings 5, and the usage method of Embodiment 3 is the same as that of Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com