Helical tooth ladder bottom-spraying type diamond bit

A diamond drill bit and helical tooth technology, which is applied in the field of geological core drilling, can solve the problems of diamond micro-burning, low rock breaking efficiency, carbonization, etc., so as to increase drilling specific pressure, improve drilling efficiency, and improve lip powder discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] combine figure 1 with figure 2 , the present invention is further described:

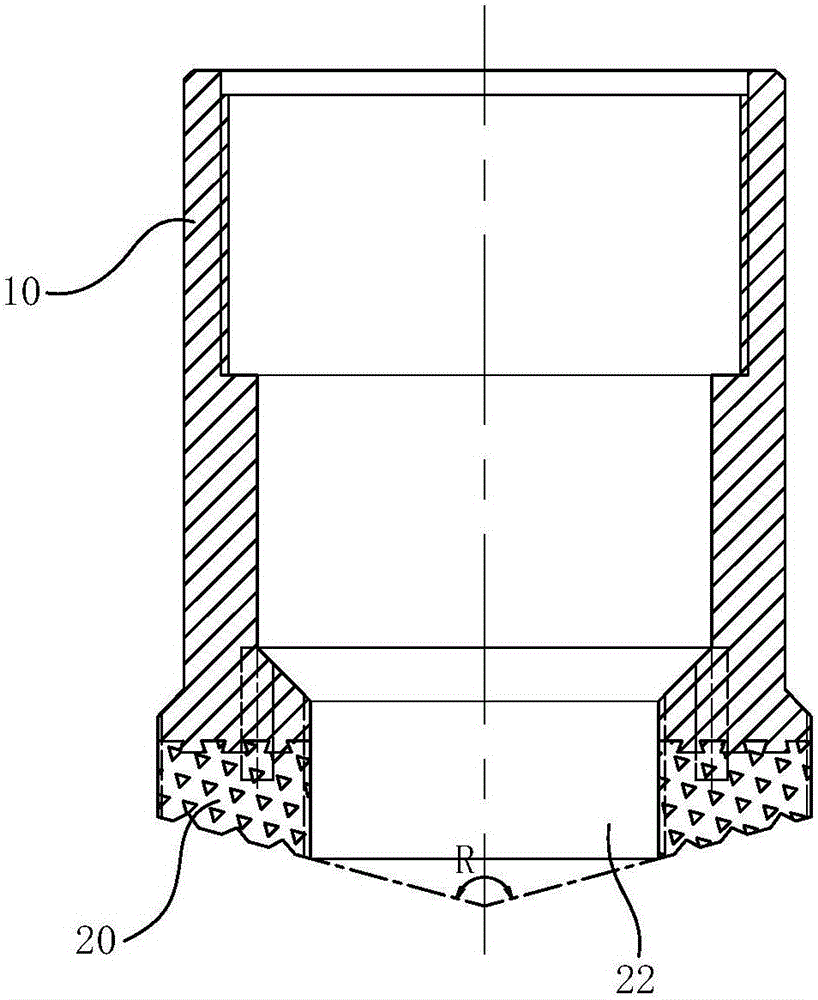

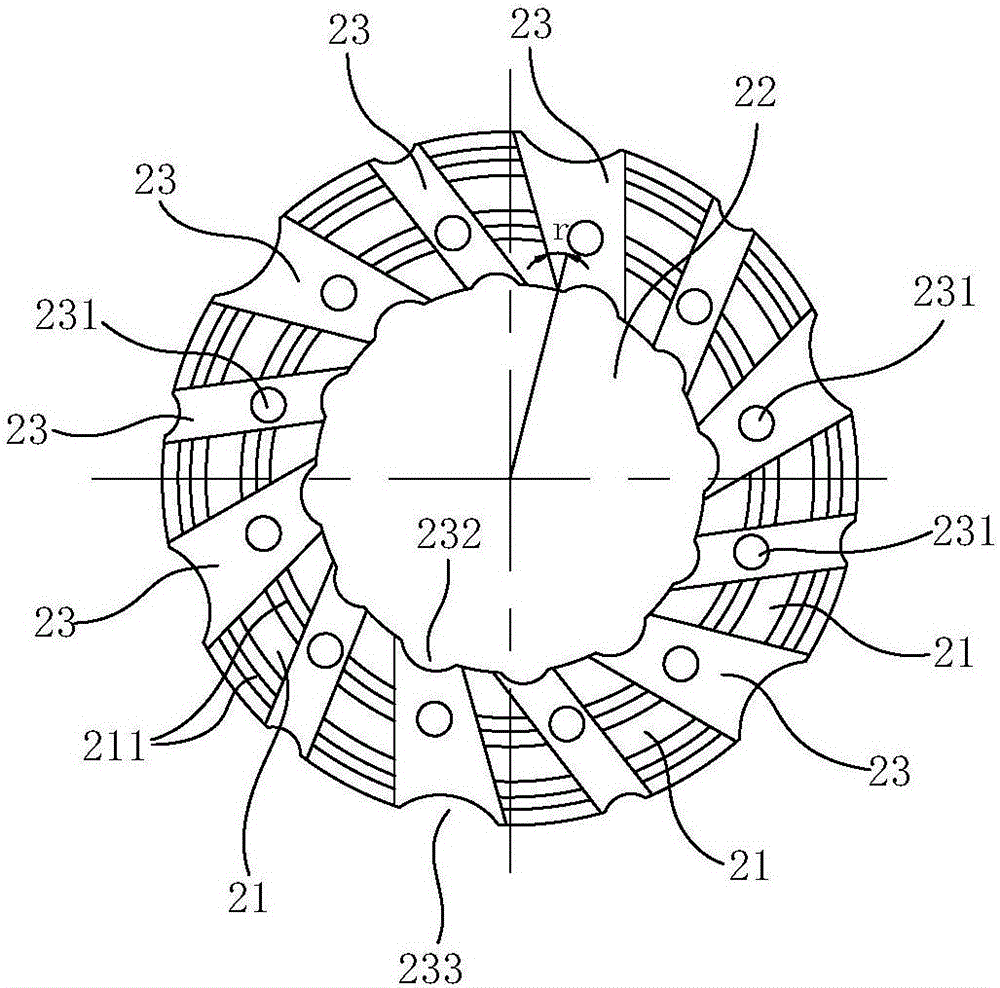

[0016] The helical-tooth stepped bottom-spray diamond drill bit includes a drill steel body 10 and a diamond working layer 20 arranged at the end of the drill steel body 10. The drill steel body 10 has a tubular structure as a whole, and the diamond working layer 20 is arranged on the pipe and the overall conical structure, the conical end of the diamond working layer 20 is provided with a core inlet 22, and a fan-shaped block 21 is arranged on the surface where the busbar of the diamond working layer 20 is located, and the fan-shaped block 21 is arranged along the A plurality of intervals are set in the circumferential direction of the fan-shaped block 21 and a fan-shaped groove 23 is formed between the fan-shaped block 21. The groove bottom of the fan-shaped groove 23 is provided with a water spray hole 231, and the water spray hole 231 is connected with the pipe cavity of the drill steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com