Laser-assisted drilling method and device

A laser-assisted, drilling method technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of reduced processing quality, tool wear, increased drill breakage, etc., to improve processing accuracy and processing efficiency, The effect of reducing tool wear and improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

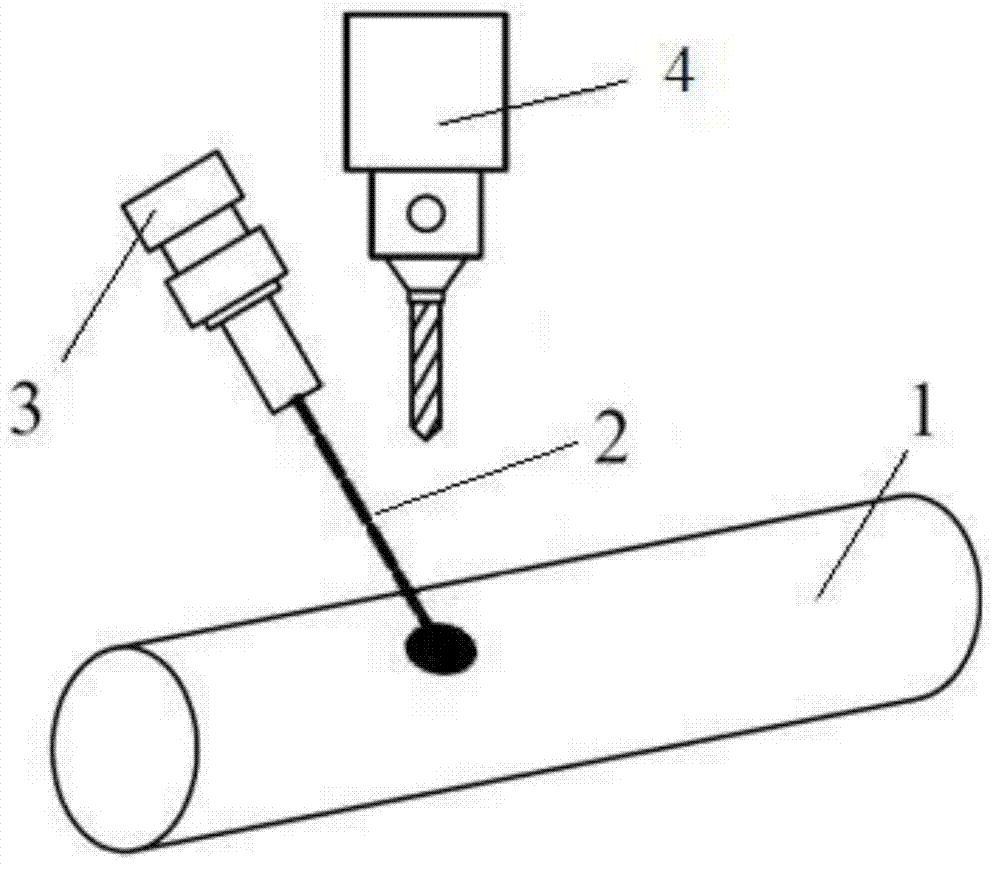

[0023] Such as figure 1 As shown, a laser-assisted drilling method provided by the present invention specifically includes the following steps:

[0024] S1. Drilling positioning: Fix the workpiece 1 by a fixture, align the laser beam 2 of a laser 3 with the hole to be drilled on the workpiece 1, and hang the drill bit 4 above the workpiece 1, and align it with the hole to be drilled.

[0025] Among them, in order to facilitate the alignment of the workpiece 1 to be drilled, the laser 3 in the present invention is required to be able to move conveniently, so the fiber laser 3 is preferred. When positioning, try to make the center of the laser beam 2 of the laser 3 coincide with the center of the hole to be drilled on the workpiece 1 .

[0026] S2. Laser heating: use the laser beam 2 of the laser 3 to heat the hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com