Double-layer cross-shaped self-drilling anchor bolt drill bit

A bolter bit, self-drilling technology, applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., can solve the problems of increasing the resistance between the drill bit and the rock and soil on the hole wall, easy drilling deviation and swing, small slag discharge groove of the cross bit, etc. , to achieve the effect of reducing swing, reducing heat and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

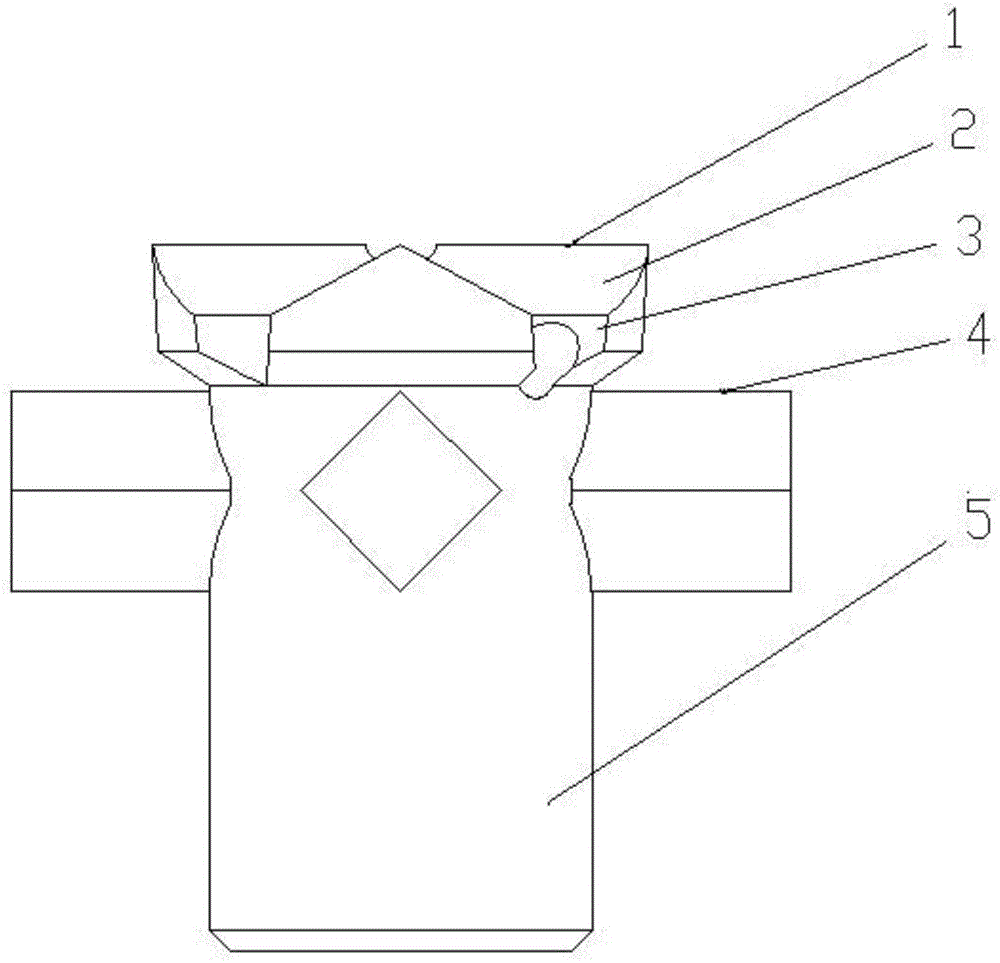

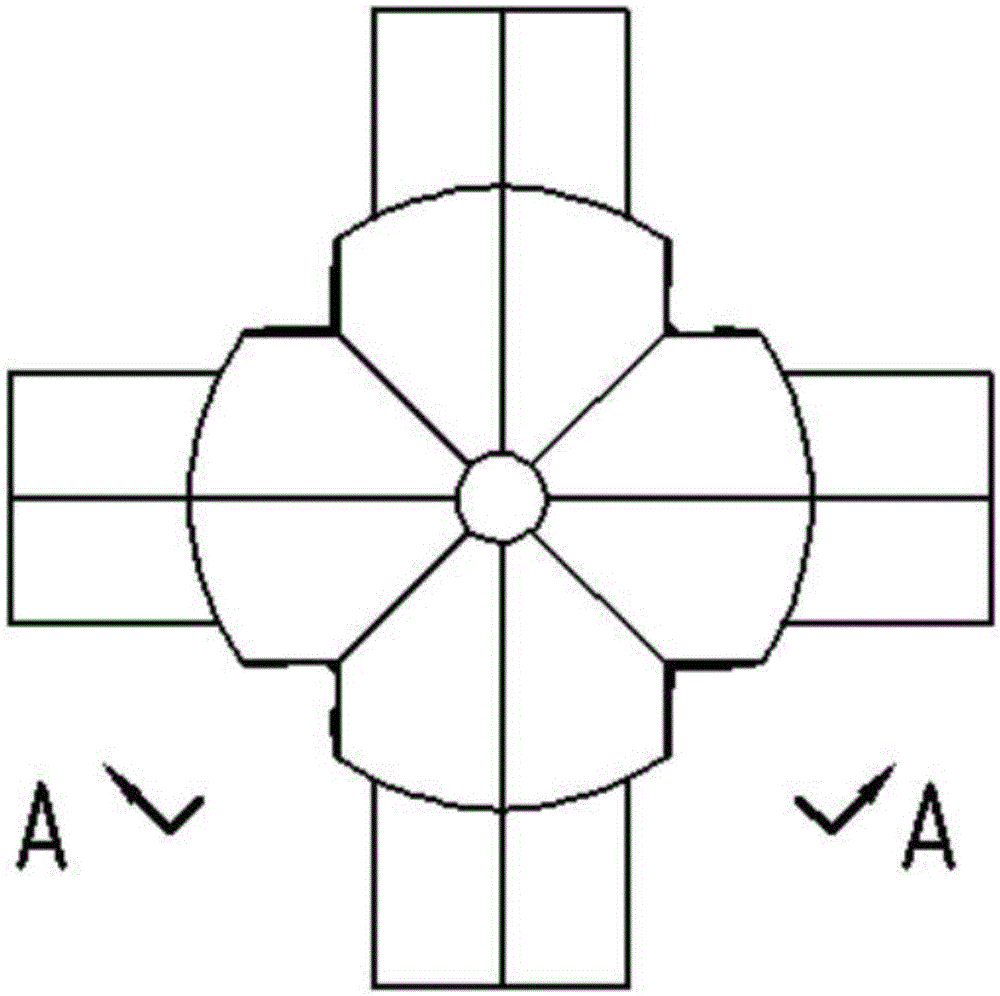

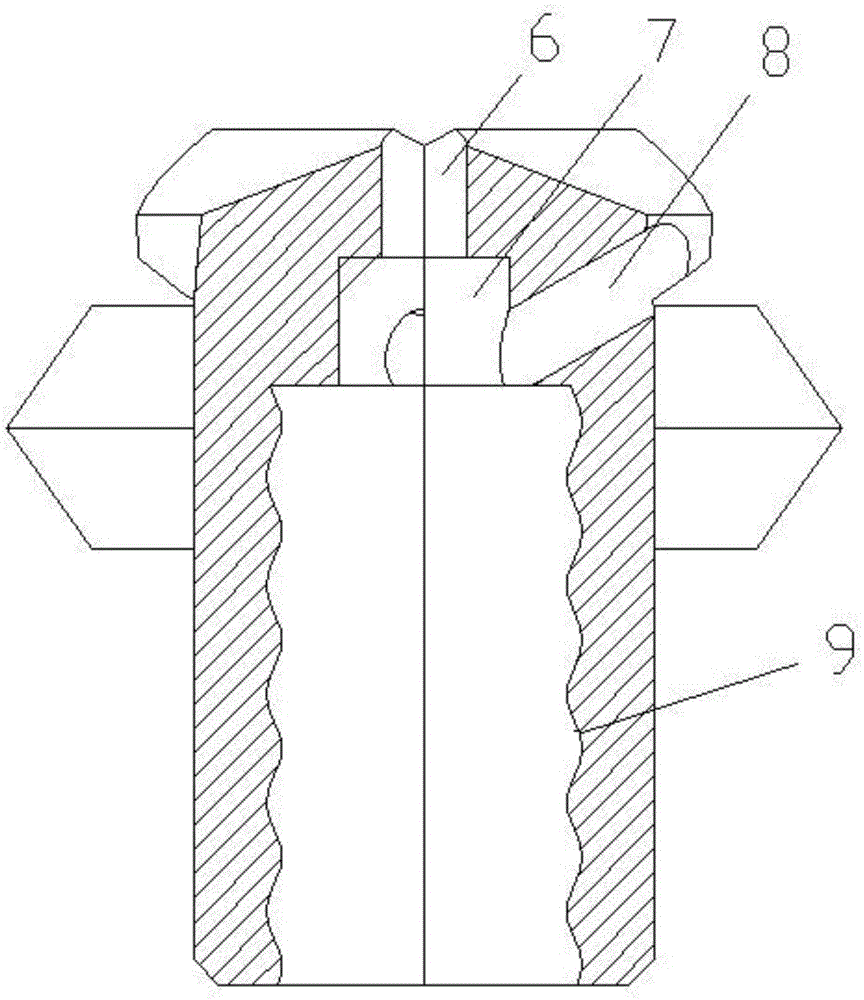

[0027] Such as figure 1 , figure 2 As shown, a double-headed cross self-drilling anchor drill bit of this patent includes a main cutting edge 1, 4 symmetrical upper slag discharge grooves 2, 4 symmetrical lower slag discharge grooves 3, 4 secondary cutting edges 4, 1 6 upper water holes, 2 side water holes 8, drill trouser body 5, internal thread 9, transition hole 7; the main cutting edge 1 is a cross edge connected to the blade, located at the top of the drill bit, and the main cutting edge 1 edge The blades are on the same plane, the diameter of the circumference of the blade is about 1.2 times the diameter of the pants body 5, and the circumference of the blade has a downward clearance angle of 1° to 2°, and the downward chamfer of 120-130° with the axis Connected with the drill body 5; the 4 secondary cutting edges 4 have the same shape, and are evenly distributed on the upper edge of the drill body 5 towards the top, and the 4 secondary cutting edges 4 are on the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com