Prefabricated screw spike pile

A screw and pile body technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low foundation pile bearing capacity, low pile body strength, low construction efficiency, etc., and achieve high single pile bearing capacity value. , The effect of reliable pile quality and fast pile formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

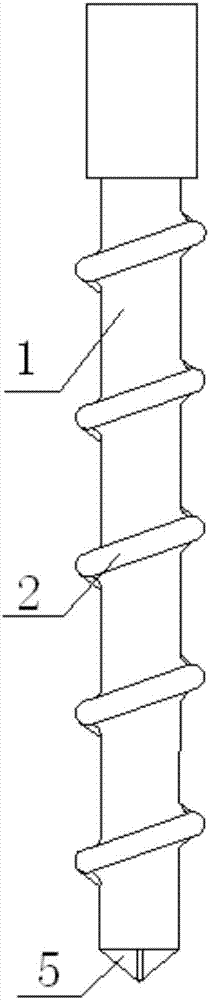

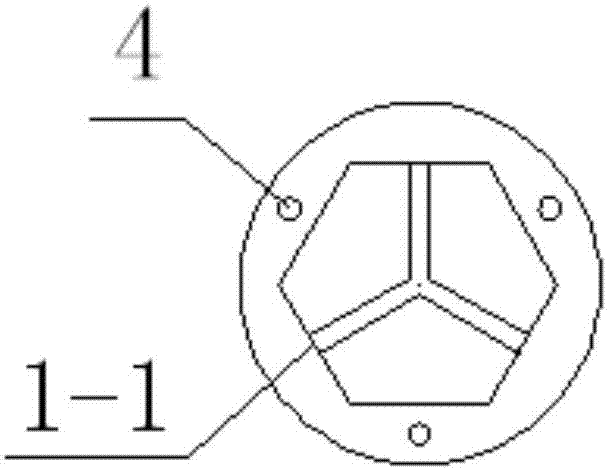

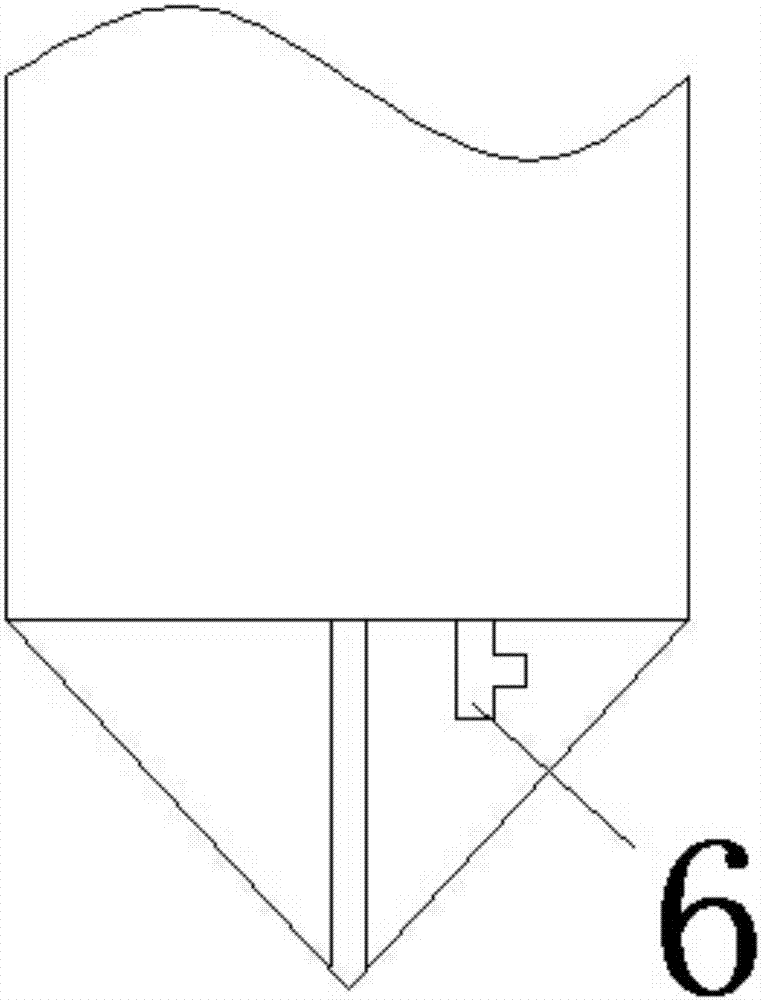

[0028] Specific embodiment 1: The prefabricated screw pile in this embodiment is composed of a single prefabricated screw pile base or connected by multiple prefabricated screw pile bases, and the concrete pile body 1 of the prefabricated screw pile base is a circular tube or a hollow cone body, the inner hole 1-1 of the pile body 1 is circular or polygonal, and the outer surface of the pile body 1 is provided with a continuous thread 2 or a continuous zigzag thread 3, along the axial direction of the pile body 1, there are at least A through hole 4 is provided with a pile tip 5 made of steel plates on the bottom end surface of the prefabricated screw pile.

[0029] The thread height of this embodiment is 10mm-50mm greater than the circular prefabricated concrete pipe (straight pile) at the rear end, and its function is to increase the diameter of the pile body top, so that the pile body can bear greater loads. The structural schematic diagram of the prefabricated screw pile d...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the strength of the concrete pile body 1 is marked as C80-C150.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the pile body 1 of the prefabricated screw pile base has a diameter of 150 mm to 800 mm and a length of 0.5 m to 40 m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com