A Soil Reinforcement Technology for Pipe-Jacking Well Opening on Soft Ground

A technology for soil reinforcement and soft soil foundation, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long construction period, low excavation efficiency, high cost, etc., and achieve short construction period, low cost, and reduced ceiling The effect of entry resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

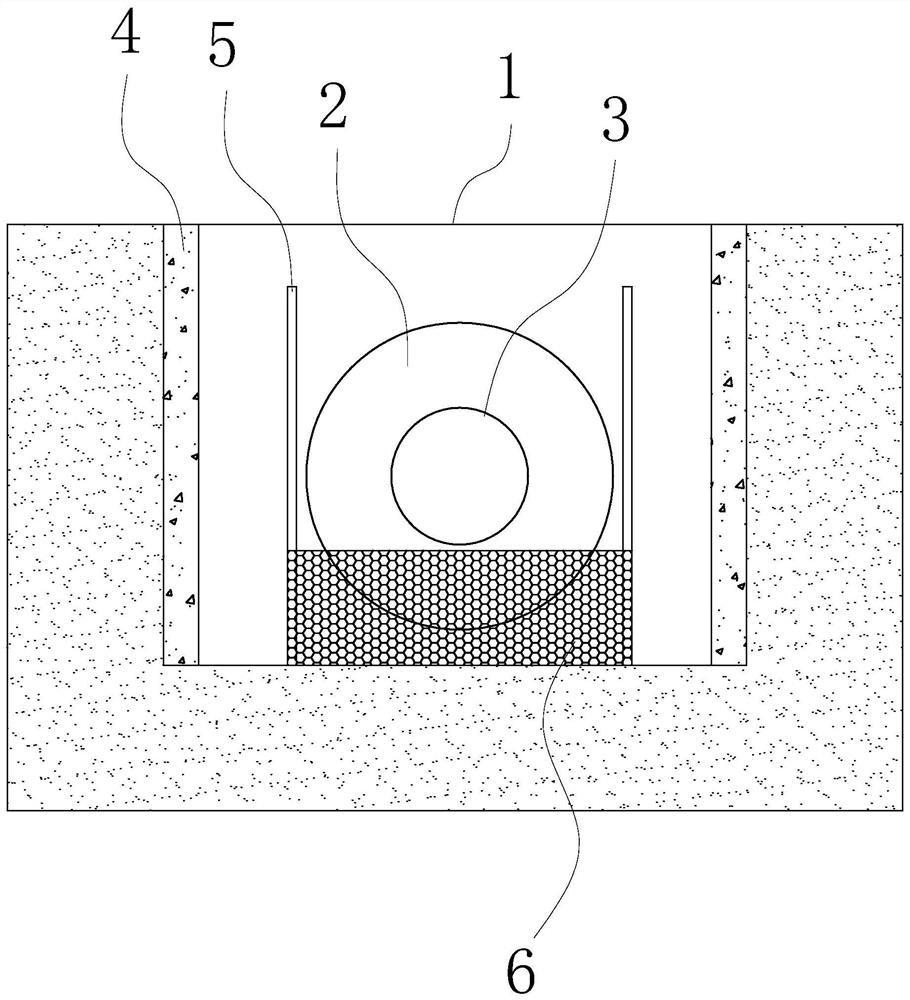

[0033] Attached to the following figure 1 This application will be described in further detail.

[0034] The embodiment of the present application discloses a soil reinforcement process for a pipe jacking well hole for soft soil foundation. refer to figure 1 , a soil reinforcement process for a pipe jacking well opening for a soft soil foundation includes the following steps:

[0035] S1. When pouring concrete for the pipe jacking well 1 to construct the enclosure 4, reserve the designed hole 3 of the pipe jacking well and a gap for reinforcement of the soil body 2 around the hole of the pipe jacking well, and pre-embed steel bars along the side wall of the gap;

[0036] S2. Draw a coil out of the hole 3 of the pipe jacking well, and compact the soil 2 around the hole of the pipe jacking in the forward direction of the pipe jacking. The soil body within 3m, within 2-3m on the upper side and from the lower side to the bottom of the well, the soil body is compacted from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com