Ground pre-grouting reinforcing process for subway tunnel surrounding rock

A pre-grouting and subway technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as weakening of surrounding rock support, large settlement, roof fall, etc., and achieve obvious reinforcement effect and expansion of reinforcement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0031] A pre-grouting reinforcement process for surrounding rock ground of a subway tunnel, comprising the following steps:

[0032] (1) Determine the surrounding rock range of the subway tunnel that needs to be reinforced, which is the target rock mass area;

[0033] The length of the surrounding rock is less than or equal to 200m; the surrounding rock mass of the subway belongs to the scope of grade IV or above, that is, the basic quality index BQ of the rock mass is greater than or equal to 251, and is suitable for subway tunnels constructed by shield tunneling method and mining method.

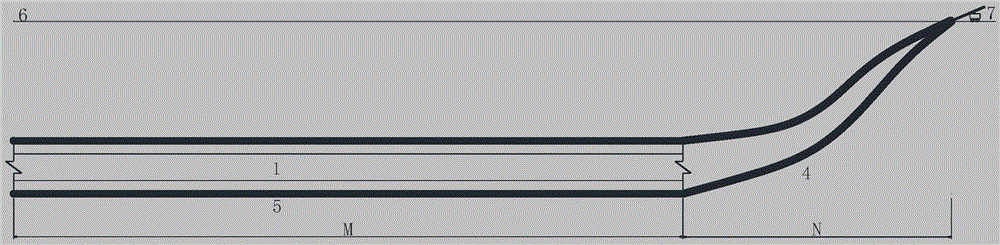

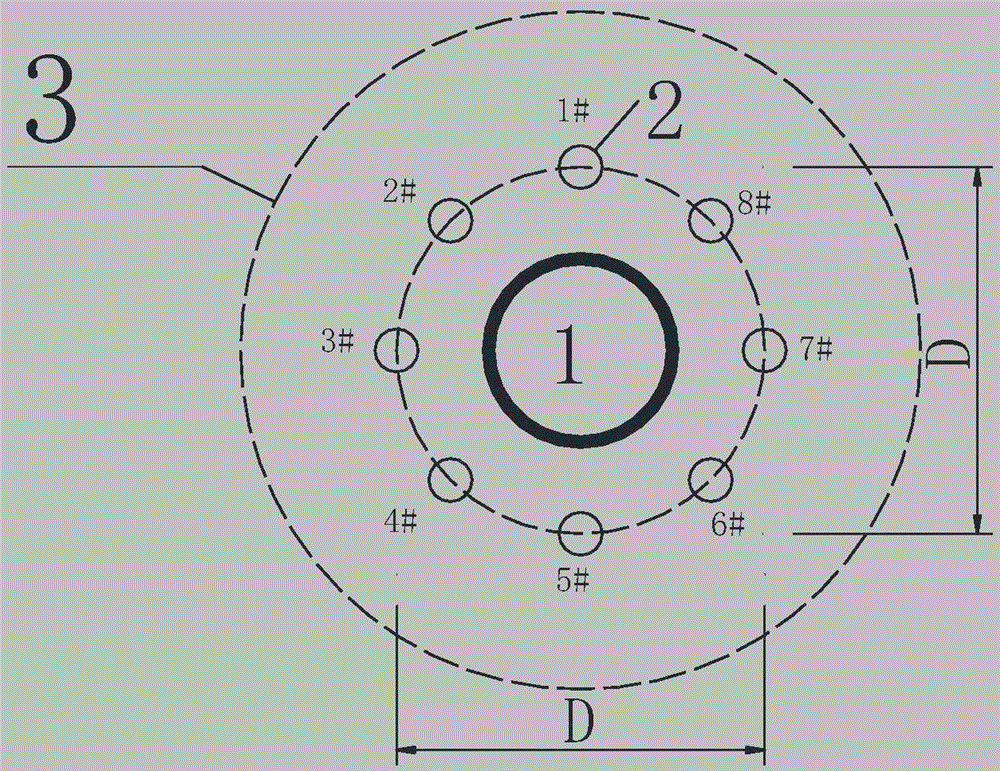

[0034] (2) Construction of inclined hole-making section: construction of inclined drilling, so that the inclined drilling is close to the target rock mass area from far to near, and gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com