Method of reinforcing masonry with fibrous fabric and matched clasping device

A technology of fiber cloth and fiber, which is applied in the field of masonry reinforcement engineering, can solve the problems of fiber cloth and component surface not sticking firmly, loss of reinforcement effect, peeling damage, etc., and achieve high strength, good reinforcement effect and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

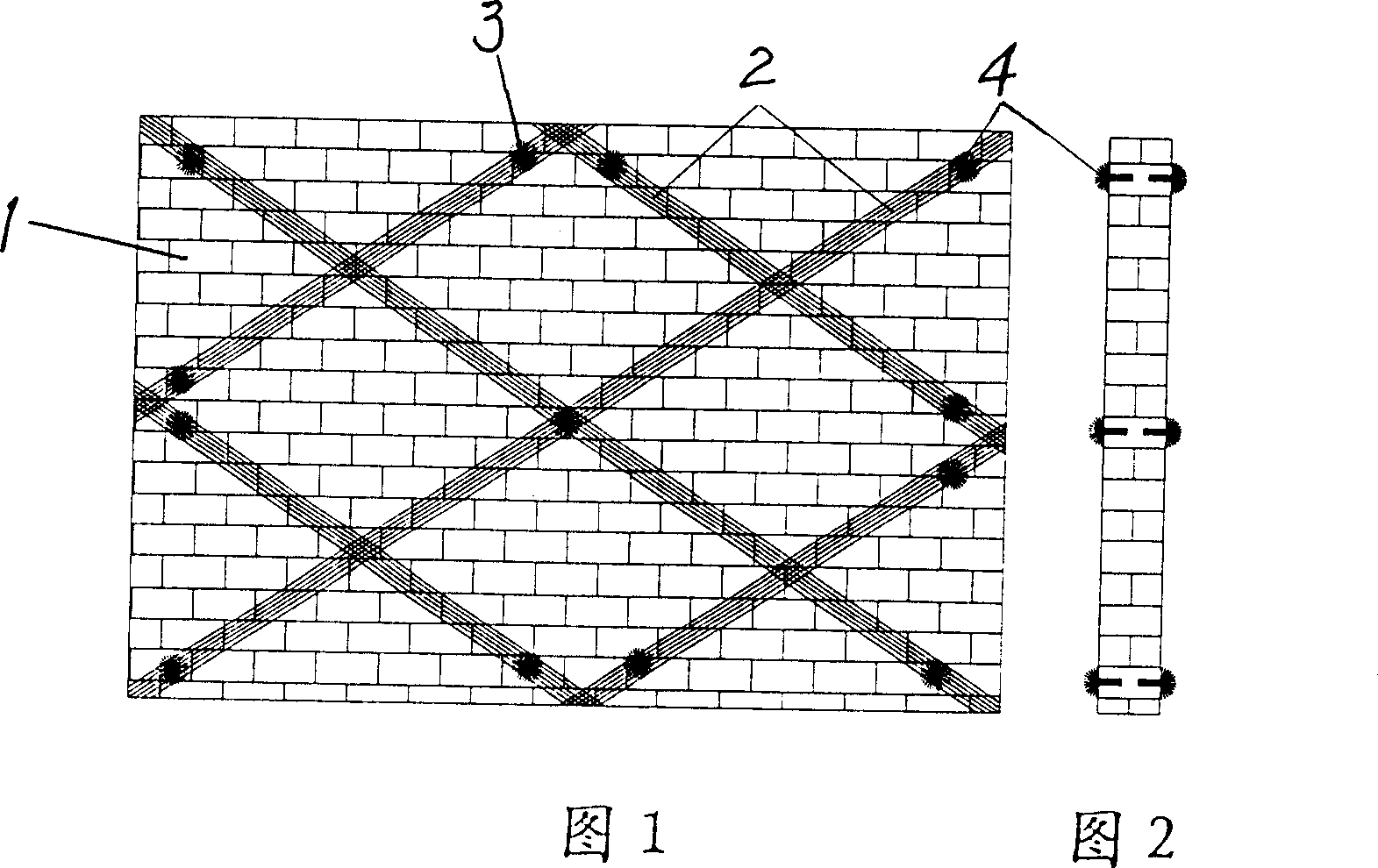

[0012] Referring to Fig. 1 to Fig. 4, the present invention is a kind of method utilizing fiber cloth to strengthen masonry. First, paste fiber cloth 2 on the surface of masonry 1, drill holes on the masonry pasted with fiber cloth, and implant fiber rivets 4 into through holes 3 of the masonry. Available common electric drill when drilling, the diameter of masonry through hole 3 is about 12mm, and the drilling depth is 50~60mm.

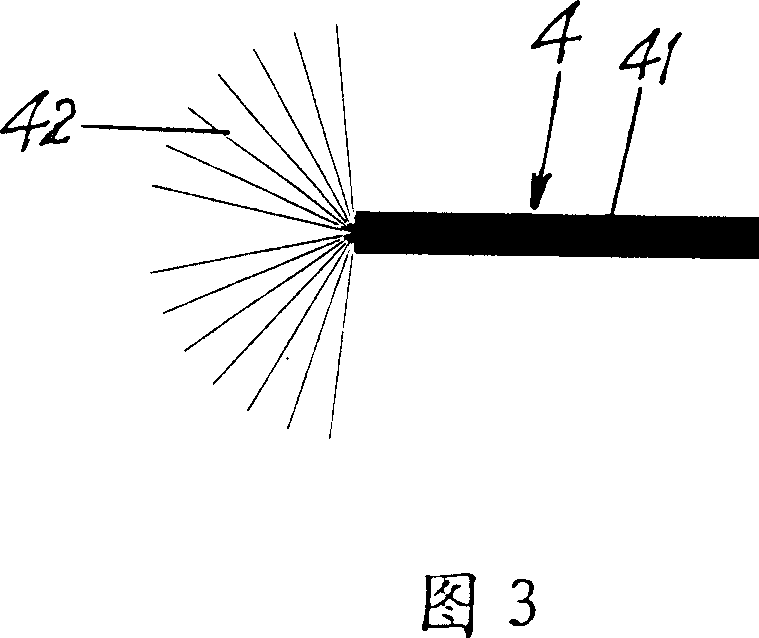

[0013] As shown in Figure 3, the fiber rivet 4 is a one-way fiber rivet made of carbon fiber cloth in a small roll shape. One end of the rivet is soaked and solidified with an adhesive to form a hard rod 41, and the other end of the rivet is disassembled into a tow shape 42 and unfolded into a fan. shape. The fiber rivet 4 can be made into a finished product, or can be made on the spot at the construction site.

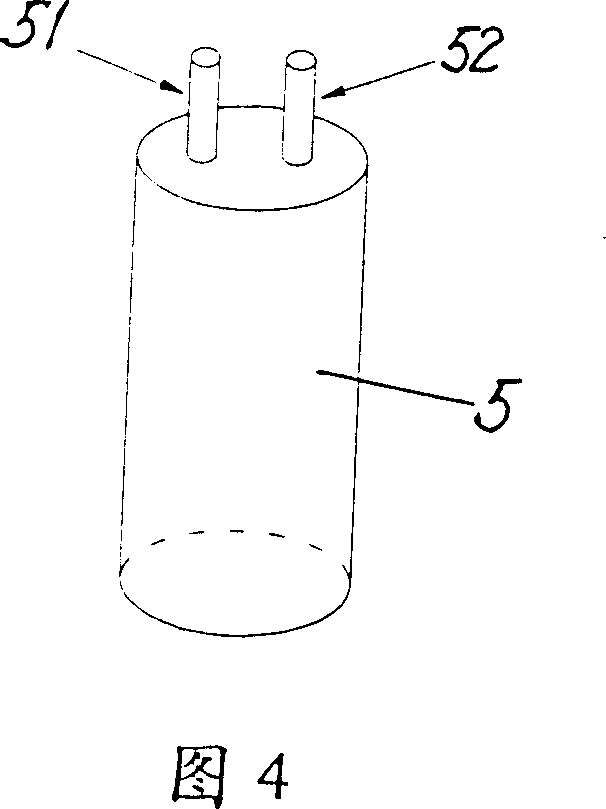

[0014] Then insert the hard rod part 41 of the fiber rivet 4 into the through hole 3 of the masonry, and inject structural adhesive into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com