Adjustable intelligent impacting and rolling combined reinforcing method

An intelligent crushing and adjustable technology, which is applied in construction, infrastructure engineering, soil protection, etc., can solve problems that cannot be fully treated, have no treatment methods, time-consuming and labor-intensive, etc., and achieve good reinforcement effects and satisfactory post-construction settlement. , Improve the effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

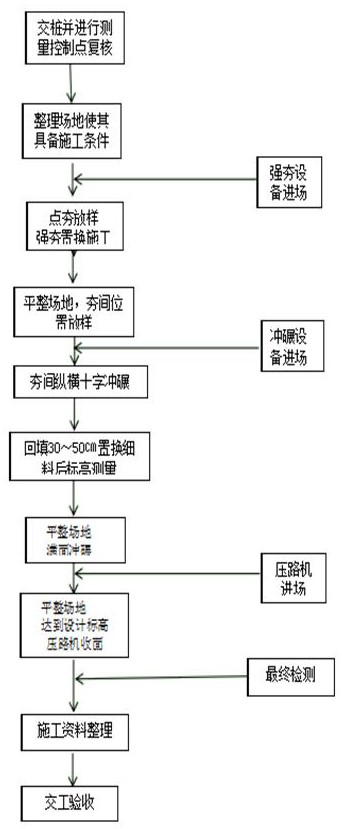

[0024] An adjustable intelligent punching and rolling combined reinforcement method comprises the following steps,

[0025] S100~Leveling the site, leveling and cleaning the original construction site, if the site is too weak for dynamic compaction equipment to walk, first lay a 30-50cm thick cushion until it is suitable for dynamic compaction construction, and then level and stake out.

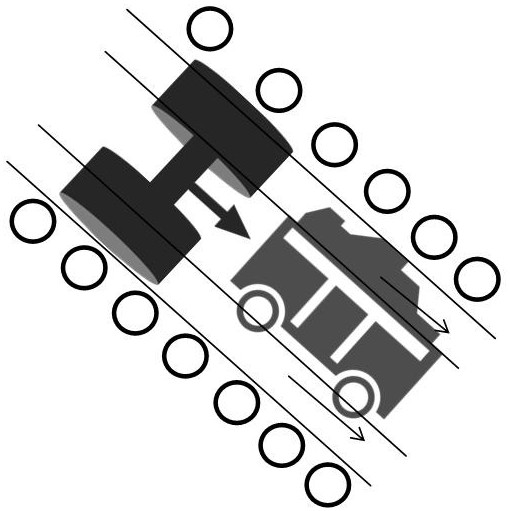

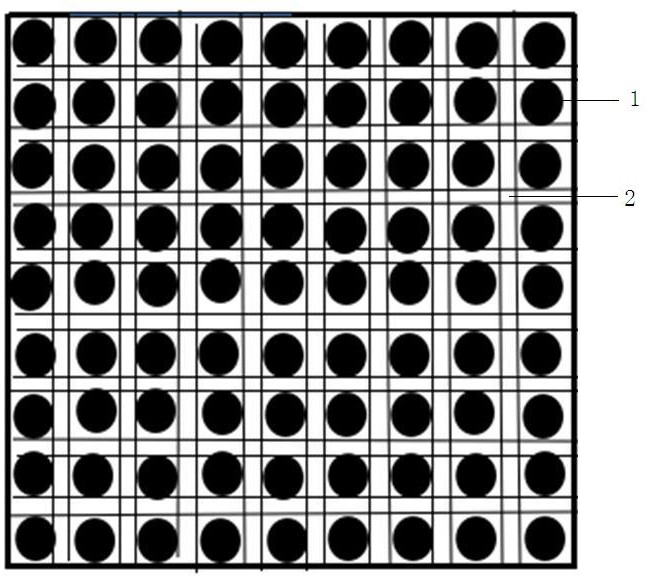

[0026] S200~Dynamic tamping replacement treatment: The first step is point tamping construction. During the tamping process of the replacement hammer, the replacement materials are sequentially backfilled into the rammed pit to form a replacement pier, and the construction is carried out point by point to form a regularly arranged replacement pier. After the construction is completed, level the site, and adjust the steel wheel spacing and steel wheel width of the impact rolling equipment according to the distance between the replaced pier bodies; during the dynamic ram replacement construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com