Comprehensive supporting system for downward penetration of important pipeline in underground excavation passage, and construction method for comprehensive supporting system

A channel and underground excavation technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of channel excavation landslides, rough construction techniques, and high safety requirements, and achieve simple construction procedures, obvious reinforcement effects, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in combination with specific embodiments.

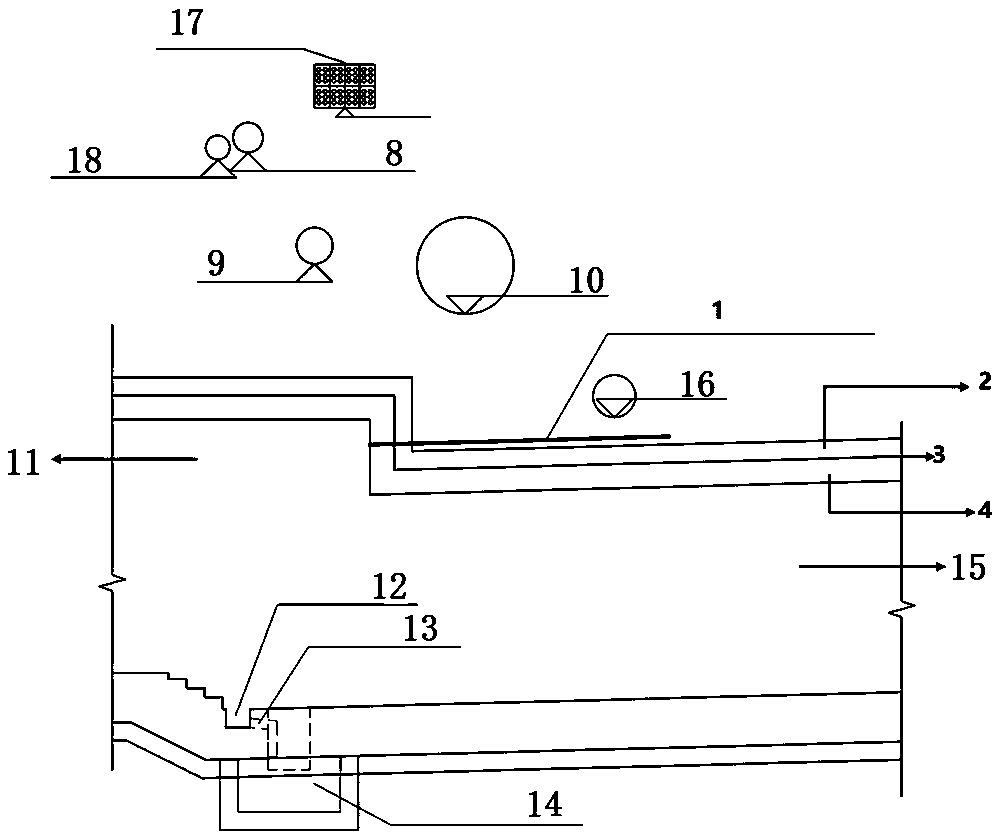

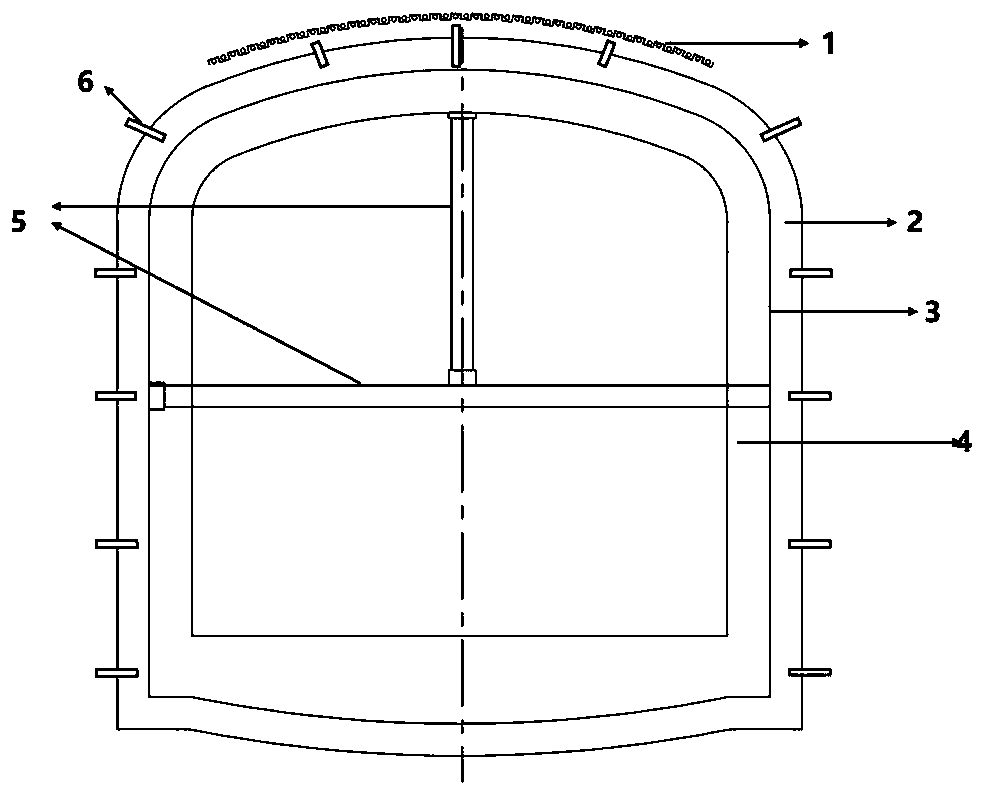

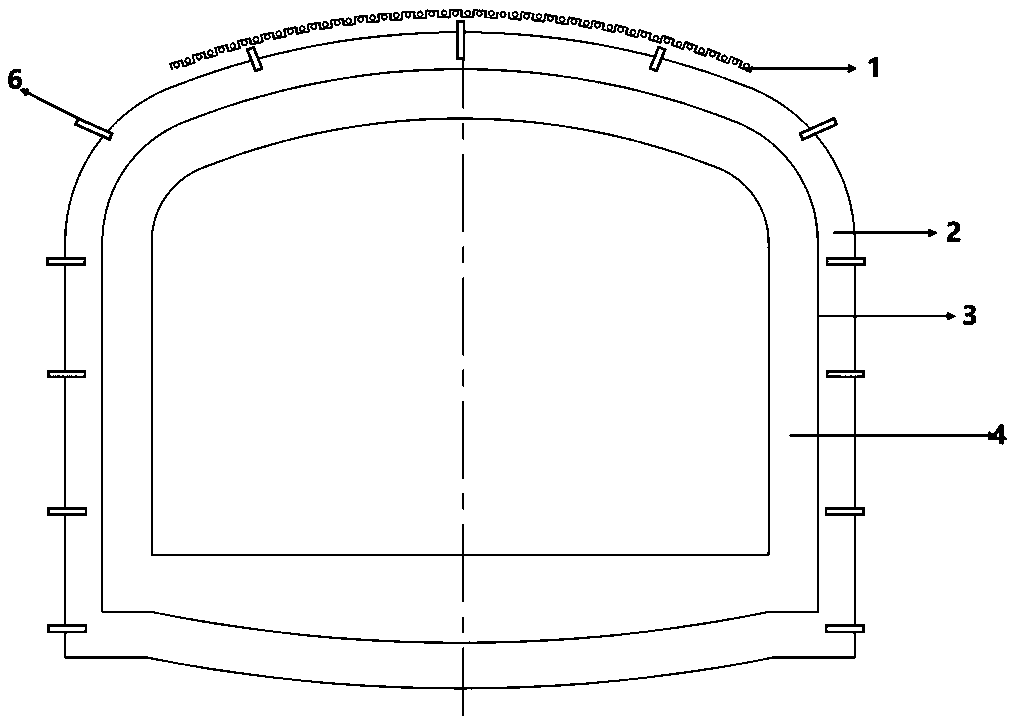

[0042] The invention relates to a comprehensive support system for an important pipeline passing through an underground excavation passage. The underground excavation passage passes through the section immediately adjacent to the important pipeline. The support system includes an elevated section 11 and a standard section 15, and the top of the elevated section 11 is It is higher than the standard section 15, and the section is larger than the standard section 15; both the elevated section 11 and the standard section 15 include primary support 2 and secondary lining 4, with temporary support 5 inside and advanced support 1 on the top.

[0043] Advance support 1 includes small grouting conduit 1-1 (Φ42) and channel steel 1-2 (10#); channel steel 1-2 is a semi-closed hollow cuboid structure with a length of 100mm, a height of 48mm, and a thickness of 5.3mm. One positive and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com