Cage shipping reinforcement method

A cage and tooling technology, which is applied to deck loading, ships, etc., can solve problems such as difficulty in ensuring stability and asymmetrical center of gravity, etc., and achieves the effects of simple production, saving area, and simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

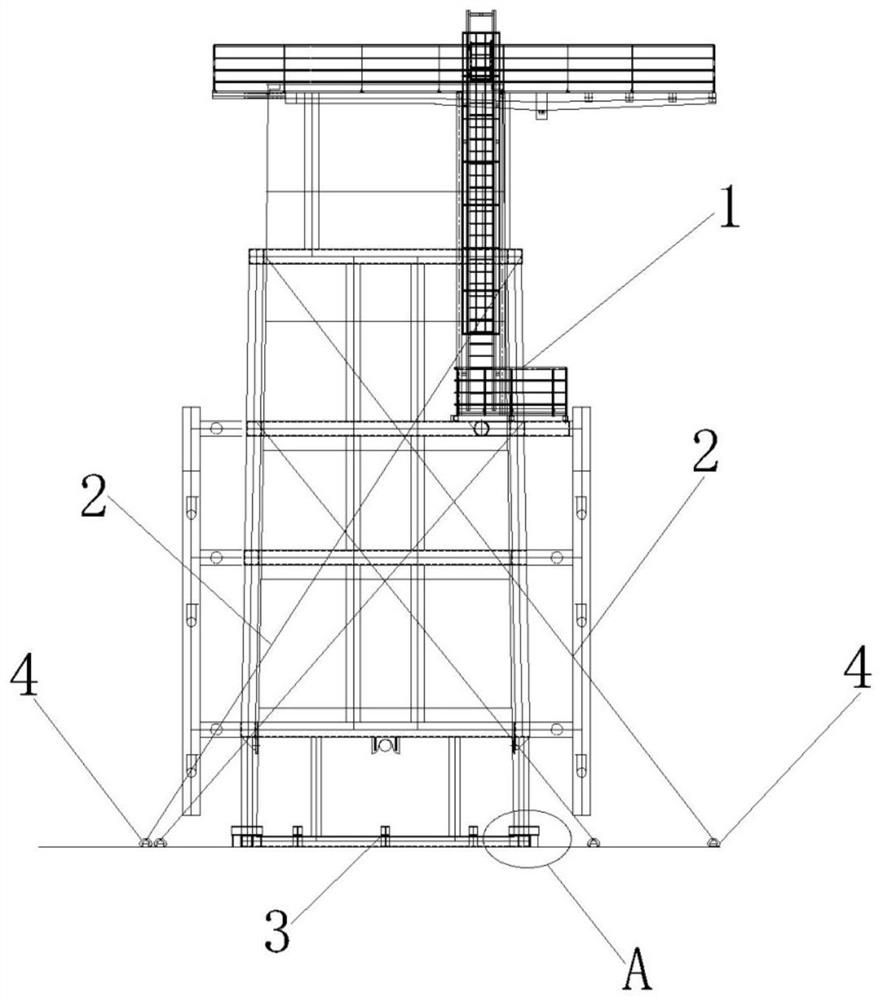

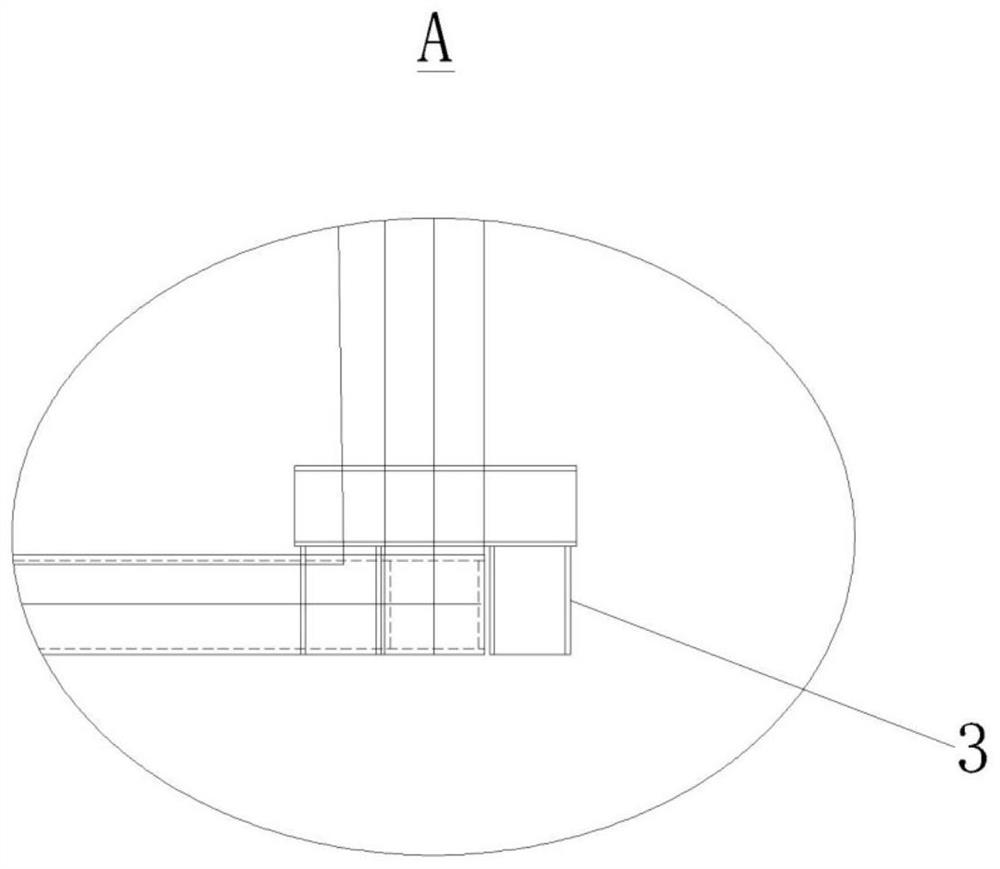

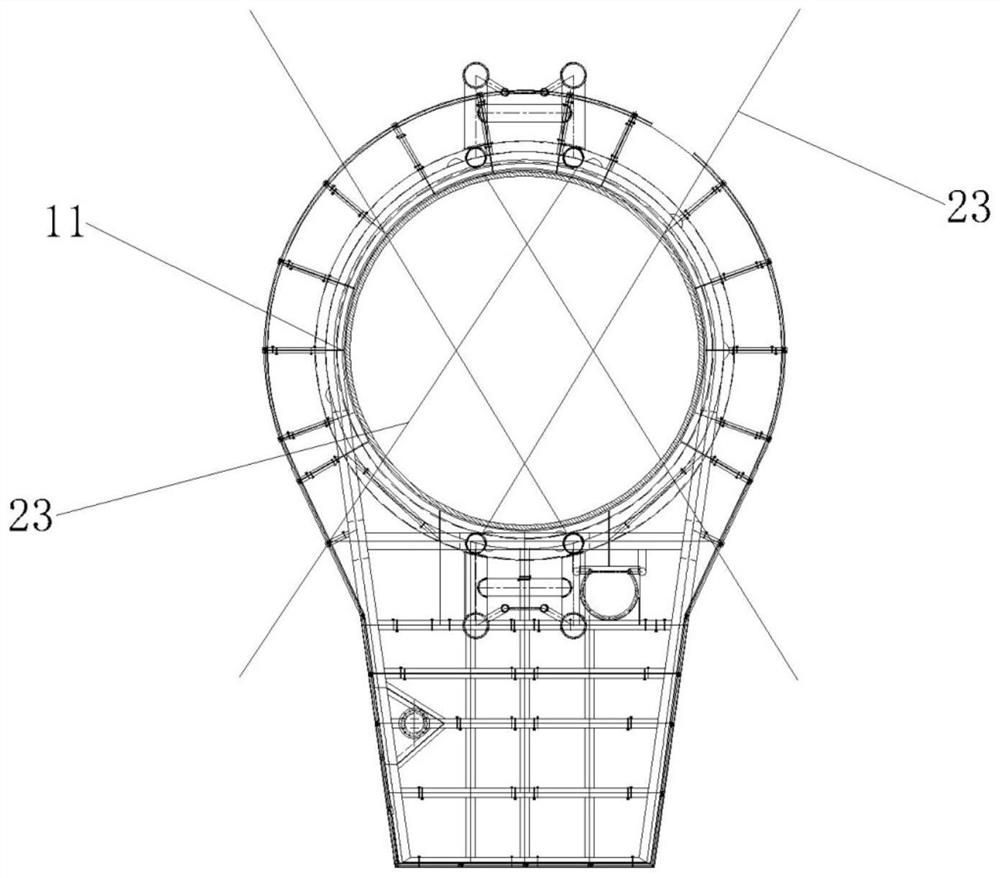

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] It should be understood that the terms "front", "rear" and the like are used in the present invention to describe various information, but the information should not be limited to these terms, and these terms are only used to distinguish the same type of information from each other. For example, "before" information could also be called "after" information, and "after" information could also be called "before" information without departing from the scope of the present invention. In the embodiment of the present invention, due to the structural design of the cage, it has multiple layers of ring beams arranged in sequence along the vertical direction, so in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com