Patents

Literature

31 results about "Yield pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yield pressure was calculated as the difference between the opening pressure of the cardia and the resting gastric pressure. Results indicated a significant decrease in yield pressure in 65 patients with esophagitis compared with 65 patients with no evidence of reflux or esophagitis.

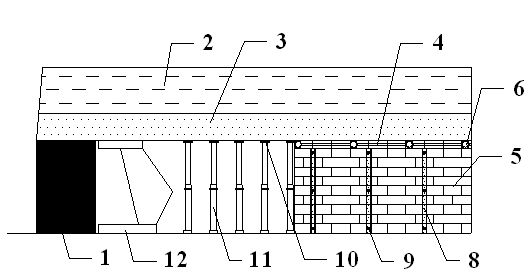

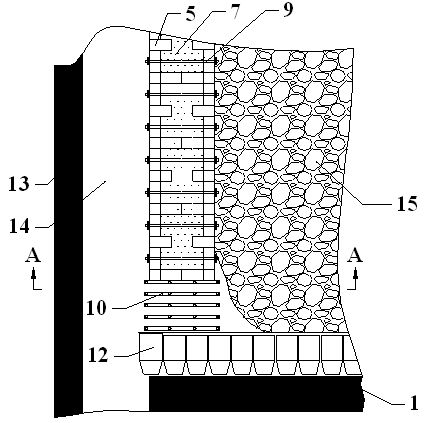

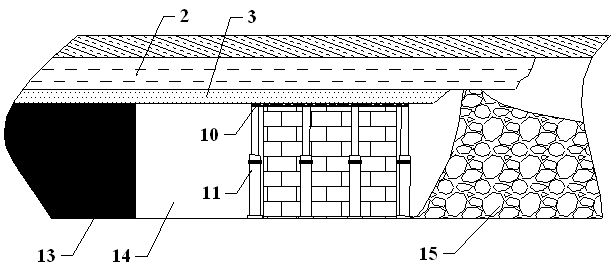

Construction method of walling and filling combined gob-side entry retaining wall body

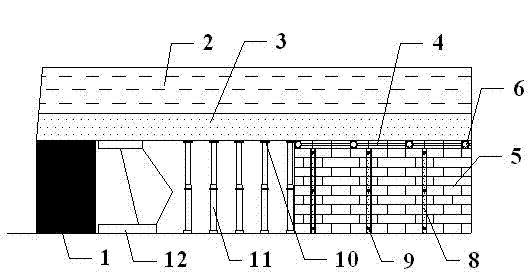

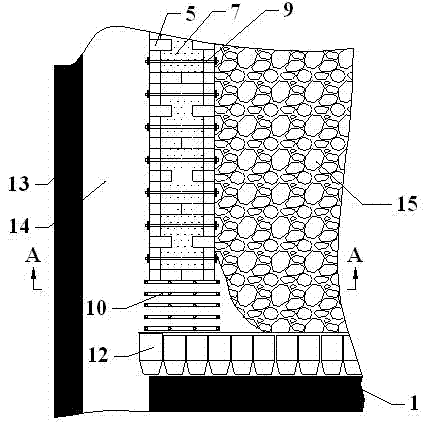

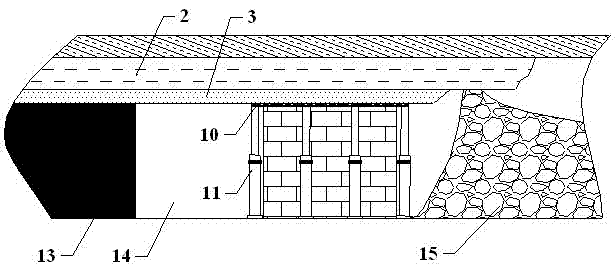

The invention relates to a construction method of a walling and filling combined gob-side entry retaining wall body. The construction method comprises the following steps of: closely following forward propulsion of a stope face, erecting dense single supports at a gob retaining side at the rear part of a fully mechanized mining bracket, so that a space of a tunnel at the rear part of the stope face is retained; walling a square template wall with concrete pier blocks under the mask of the dense single props; meanwhile, installing counter-pulled anchor rods which penetrate through the template wall bodies, and carrying out lateral reinforcing on the template wall bodies; carrying out grouting filling on a hollow part defined by the template walls through injected holes reserved on the template walls till the internal spaces of the template walls are filled with grout; carrying out uniform whitewashing treatment on the wall at one side of a gob retaining tunnel to form a concrete spray layer; and sequentially circulating the steps along with propulsion of the stope face till construction of the whole gob-side entry retaining wall body is finished. According to the construction method disclosed by the invention, a brickwork wall and a filling support are combined together, so that the construction method is simple and convenient and simple to operate and ensures that the wall body has high strength and can yield pressure suitably; and length of each walling of the wall body is consistent with the everyday propulsion degree of the stope face, and the construction method is flexibly suitable for actual mining.

Owner:CHINA UNIV OF MINING & TECH

Titanate coupling agent modified polyvinyl chloride pipe material and manufacturing method thereof

InactiveCN102002198AAbundant raw materialsConforms to the safety evaluation standardGeneral water supply conservationRigid pipesPolyvinyl chloridePrice ratio

The invention discloses a titanate coupling agent modified polyvinyl chloride pipe material and a manufacturing method thereof, which belong to modified polyvinyl chloride novel polymer composite materials. The titanate coupling agent modified polyvinyl chloride pipe material makes use of a titanate coupling agent modified polyvinyl chloride composite material, and comprises the following components in part by mass: 100 parts of polyvinyl chloride resin SG-5, 4 to 5 parts of stabilizing agent, 6 to 8 parts of impact modifier, 0.8 to 1.0 part of lubricant, 1.0 to 1.5 parts of titanate coupling agent, 3 to 5 parts of flame retardant, 10 to 40 parts of light calcium carbonate filler, and a proper amount of pigment. The pipe material has the following properties that: the tensile yield pressure is 50 MPa, the insulation resistance is 1.33*1,011 ohm, no crack is generated when the pipe material is bent for 270 degrees, the self-extinguishing time is 1 S, and the pipe material accords with the 'standard for safety evaluation of equipment and protective materials in drinking water system'. The pipe material has the advantages of excellent mechanical properties, flame retardant property, weathering resistance, insulating property and processability, high smoothness and high performance price ratio, and is energy-saving, sanitary and environmentally-friendly.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

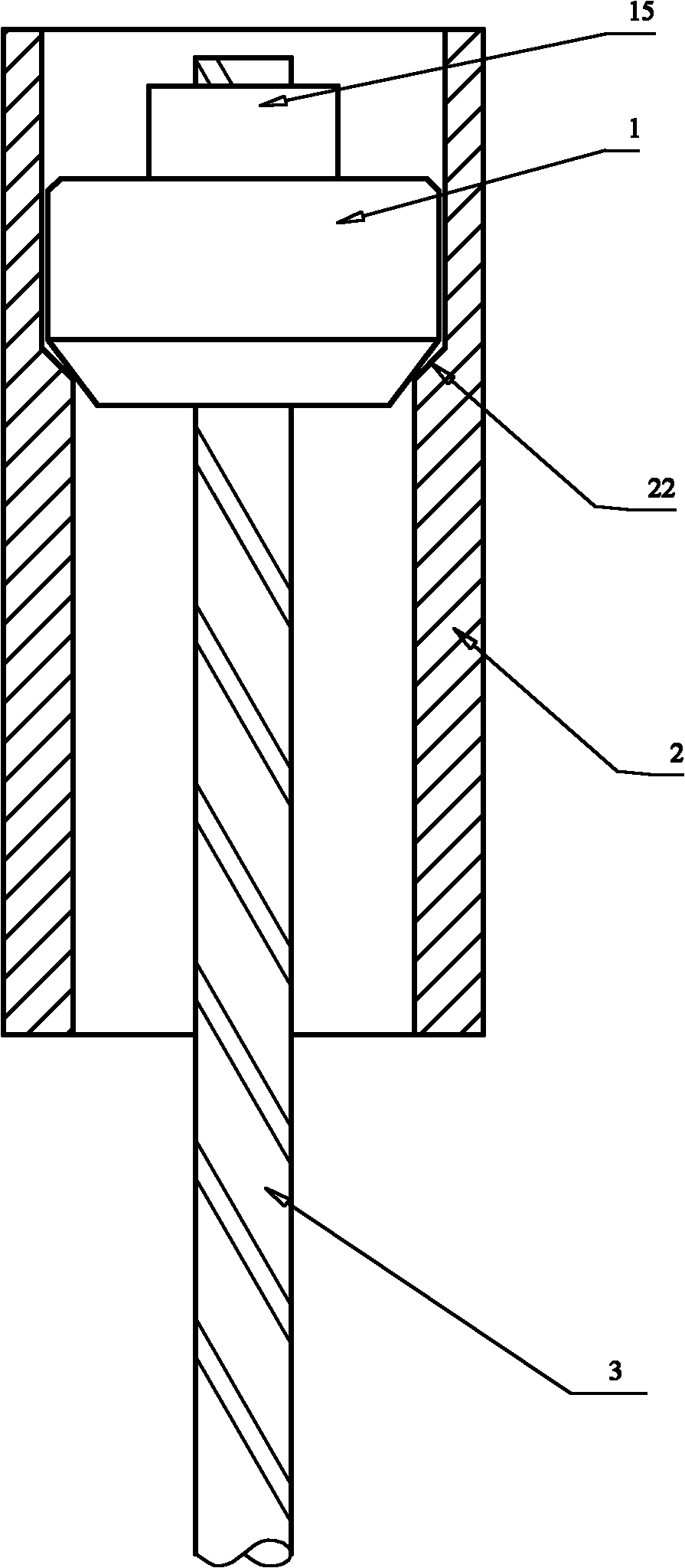

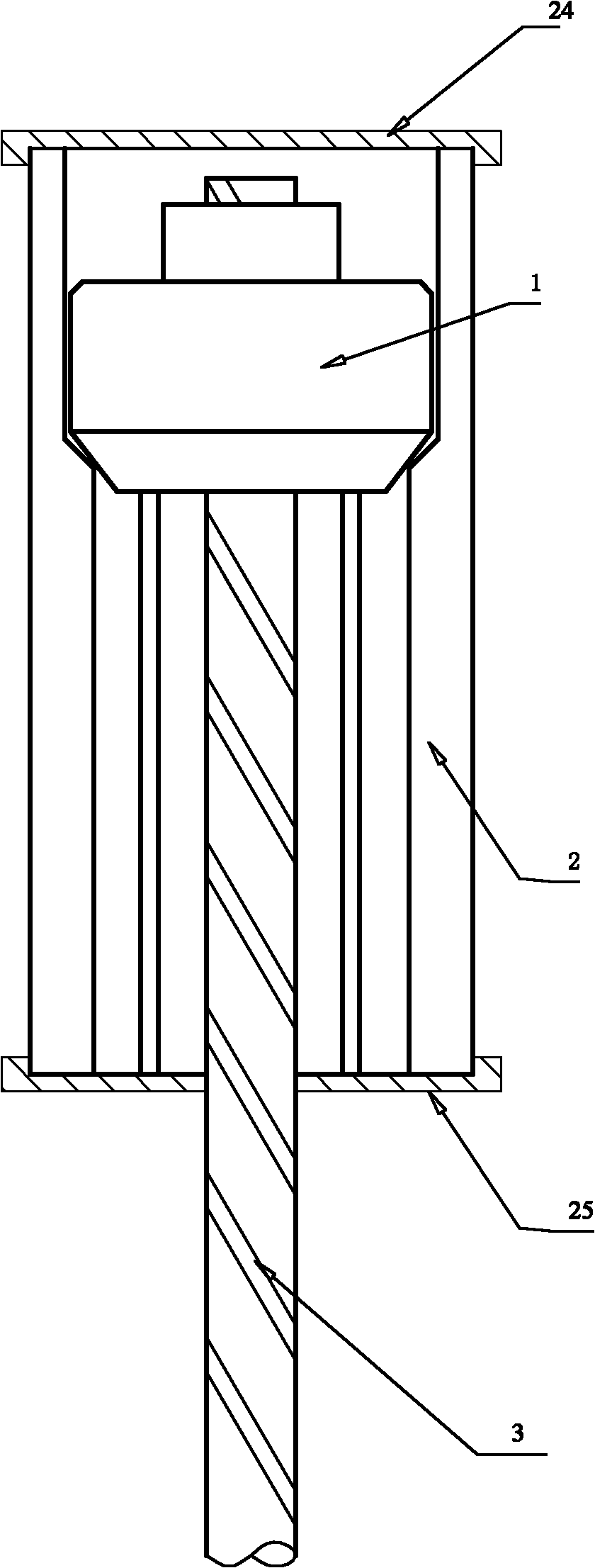

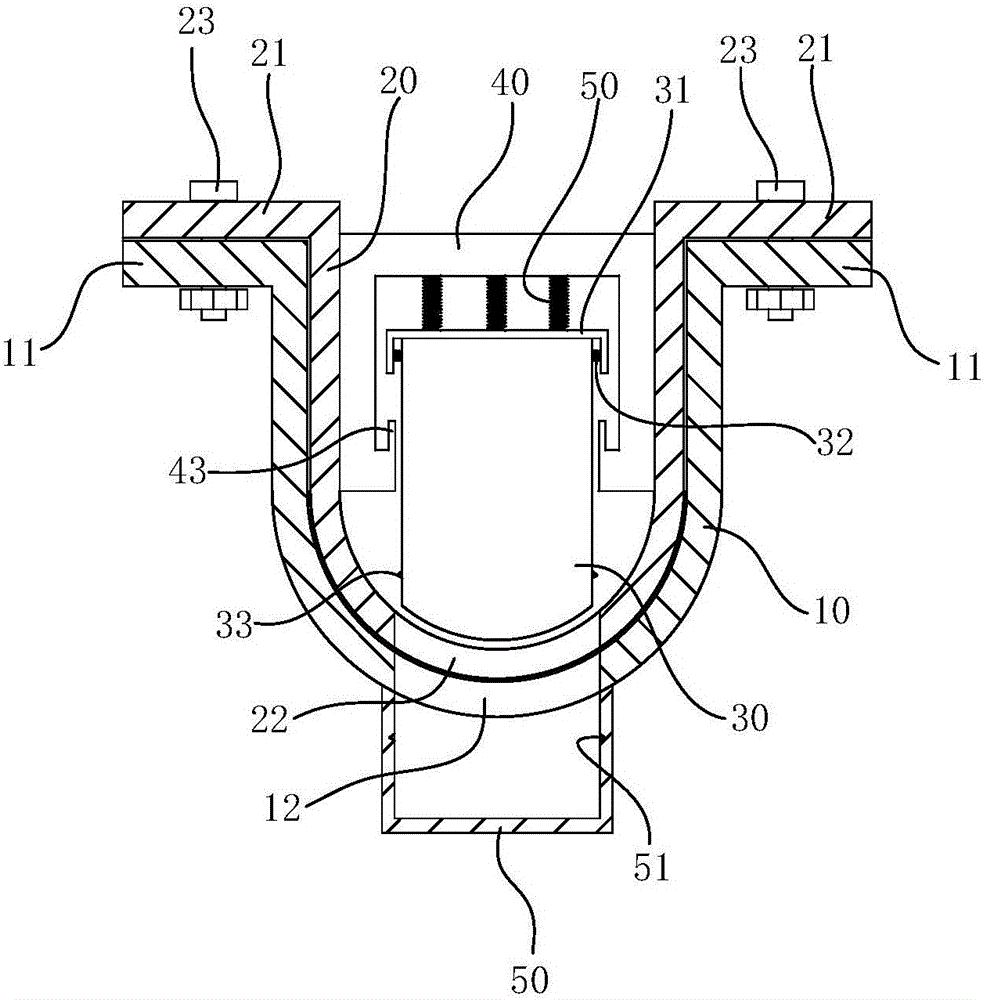

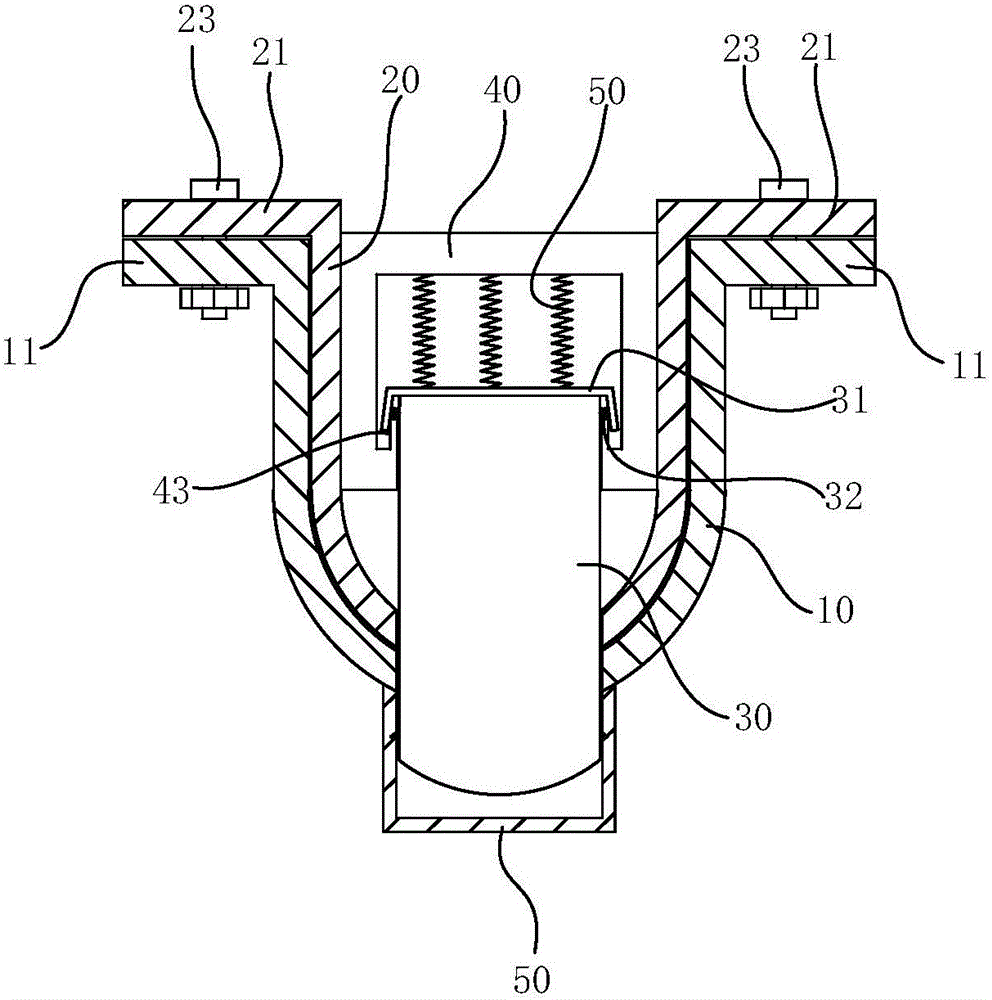

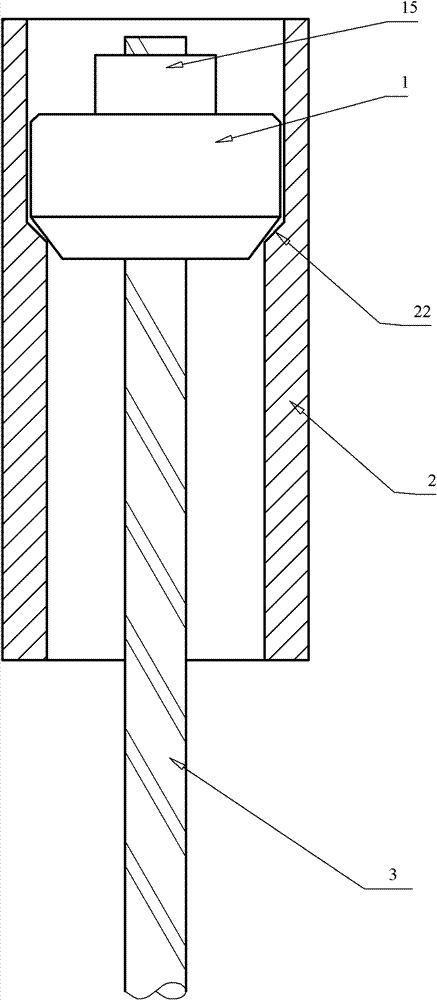

Pressure-yielding anchor device

ActiveCN102182182AMechanical properties unchangedDoes not affect the space outside the holeBridge structural detailsBulkheads/pilesEngineeringYield pressure

The invention discloses a pressure-yielding anchor device, which comprises an extrusion head, a pressure-yielding sleeve and anchor bars, wherein the extrusion head is a cylinder with the conical surface at the lower part and movably connected with the anchor bars into a whole; and the extrusion head is arranged in the pressure-yielding sleeve, the raised surface matched with the conical surface at the lower part of the extrusion head is arranged on the inner wall of the pressure-yielding sleeve, the pressure-yielding sleeve is a steel pipe with a raised edge on the inner wall preferably, andthe raised surface matched with the conical surface of the extrusion head is arranged at the end part of the raised edge. By adopting the pressure-yielding anchor device, the purposes of yielding pressure, dissipating energy and controlling deformation can be realized during anchoring, and the pressure-yielding anchor device is applicable to the anchor bars made of any material. The pressure-yielding anchor device is convenient to manufacture, reliable in effects and applicable to different engineering needs.

Owner:杭州图强工程材料有限公司

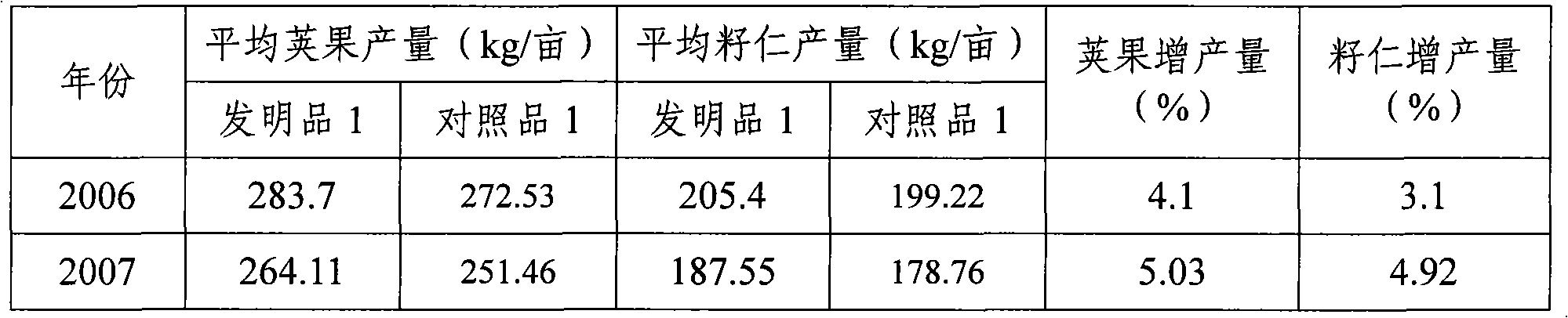

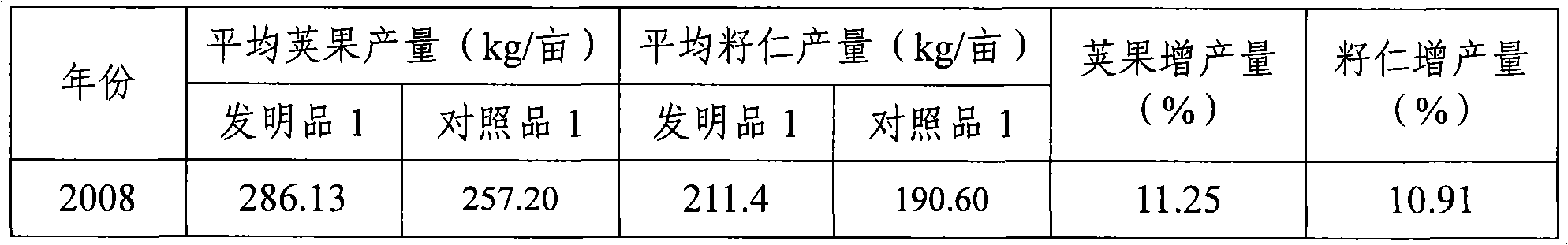

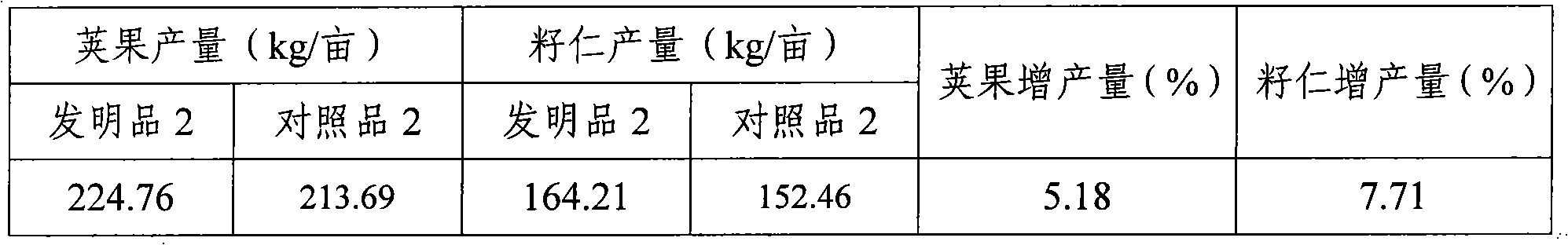

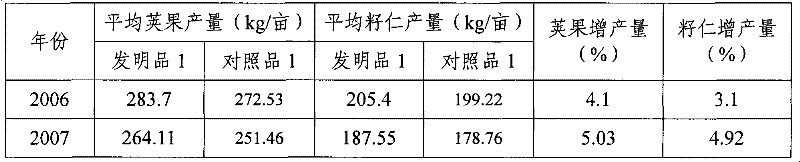

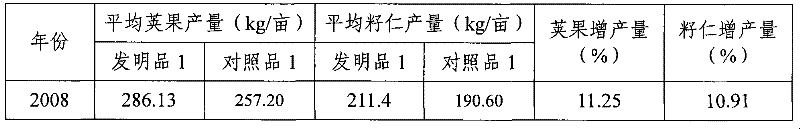

Breeding method for high-oleic acid high-yield peanut

InactiveCN101513170AGood characterImprove efficiencyPlant genotype modificationAngiosperms/flowering plantsSocial benefitsAgricultural science

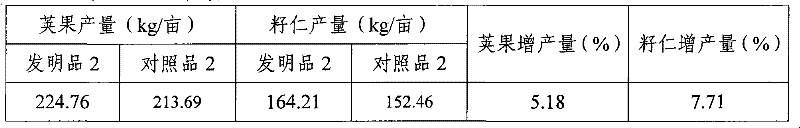

The invention provides a breeding method for high-oleic acid high-yield peanut, which includes steps: (1) coordinate parent combination: selecting high-yield germplasm with good integrated character and germplasm with high oleic acid content SPI098 to combine patent; (2) high oleic acid pressure screening: determining oleic acid of each seed in excellent single plant in early separation generation, and selecting excellent peanut seed with high oleic acid content; (3) high-yield pressure screening: planting the screened peanut seed with high oleic acid content in next generation, separating generation in anaphase, and selecting excellent high-yield single plant; and (4) high-oleic acid high-yield peanut variety or strain obtaining: obtaining novel high-oleic acid high-yield peanut variety or strain through multi-generation high-oleic acid high-yield pressure screening. The breeding method provided by the present invention directly screens according to character of oleic acid content in peanut seed, and has advantages of short breeding period, small blindness, high efficiency, and good economic benefit and social benefit.

Owner:SHANDONG PEANUT RES INST

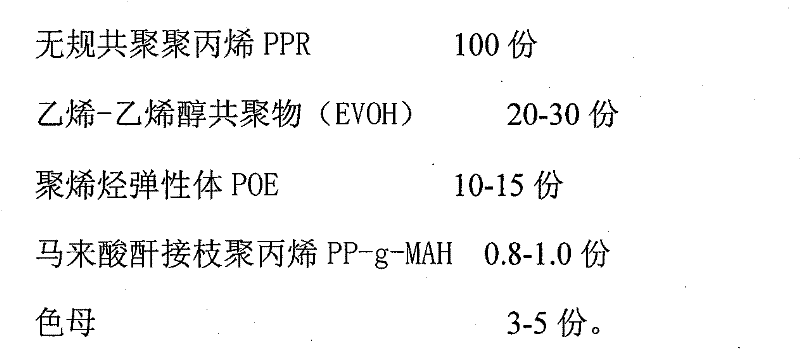

PPR/EVOH/POE (Pentatricopeptide Repeats/Ethylene-Vinyl Alcohol/Polyolefin Elastomer) blending high-impact barrier pipe and manufacturing method thereof

The invention discloses a PPR / EVOH / POE (Pentatricopeptide Repeats / Ethylene-Vinyl Alcohol / Polyolefin Elastomer) blending high-impact barrier pipe and a manufacturing method thereof, belonging to the field of novel polymeric composite materials. A blending system is formed through physical blending by compositely using PPR, EVOH and POE and compatibilization is carried out on the blending system by adopting a PP-g-MAH (Polypropylene-grafting-Maleic Anhydride) nucleating agent, thus the problems of low temperature brittleness, oxygen and permeability resistance, corrosion resistance, ageing resistance, heat resistance, processability, and the like of a PPR pipe are effectively solved. The PPR / EVOH / POE blending high-impact barrier pipe has the following performances that: drawing yield pressure is 48 MPa, the impact strength of a freely supported beam is 3.6 KJ / m<2>, and oil absorption rate is 0.5%, longitudinal retraction rate is 1%; seepage and crack do not exist in hydrostatic tests and heat stability tests in hydrostatic states; and the PPR / EVOH / POE blending high-impact barrier pipe meets the safety evaluation criterion of domestic drinking water delivery and distribution equipment and protective materials. The invention can be widely applied to the fields of municipal and building water supply, heating, gas supply, electric power, communication, industry, agriculture, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

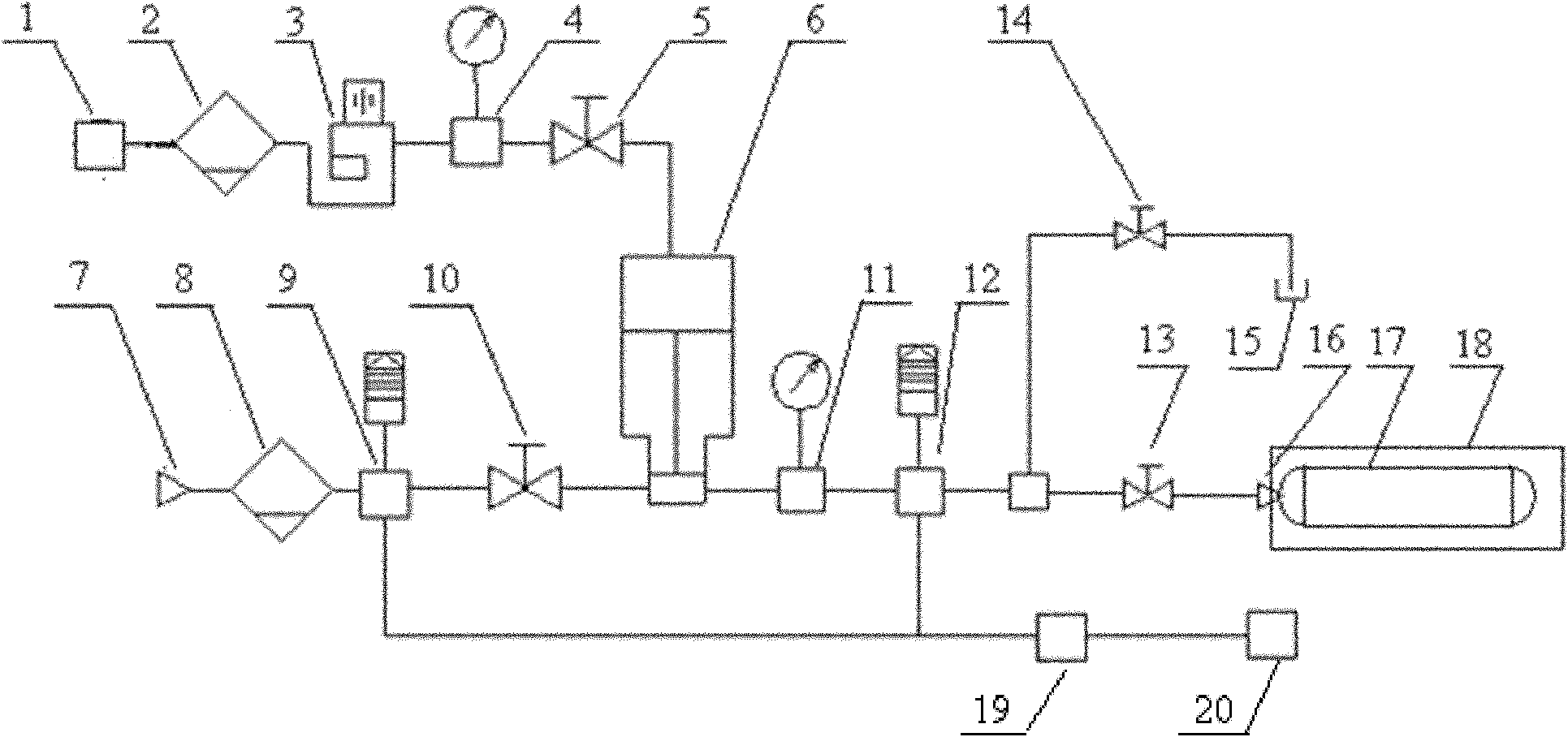

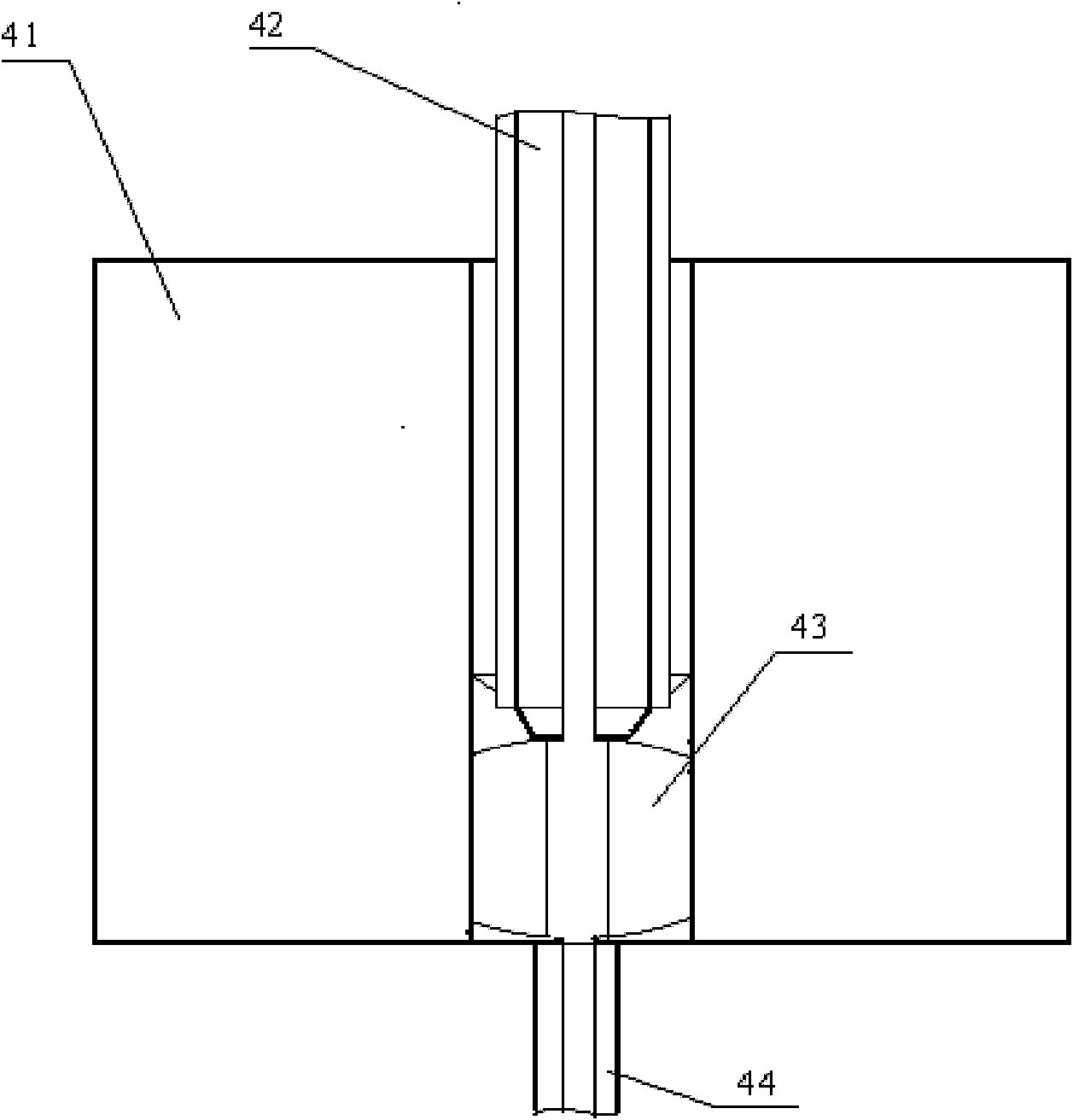

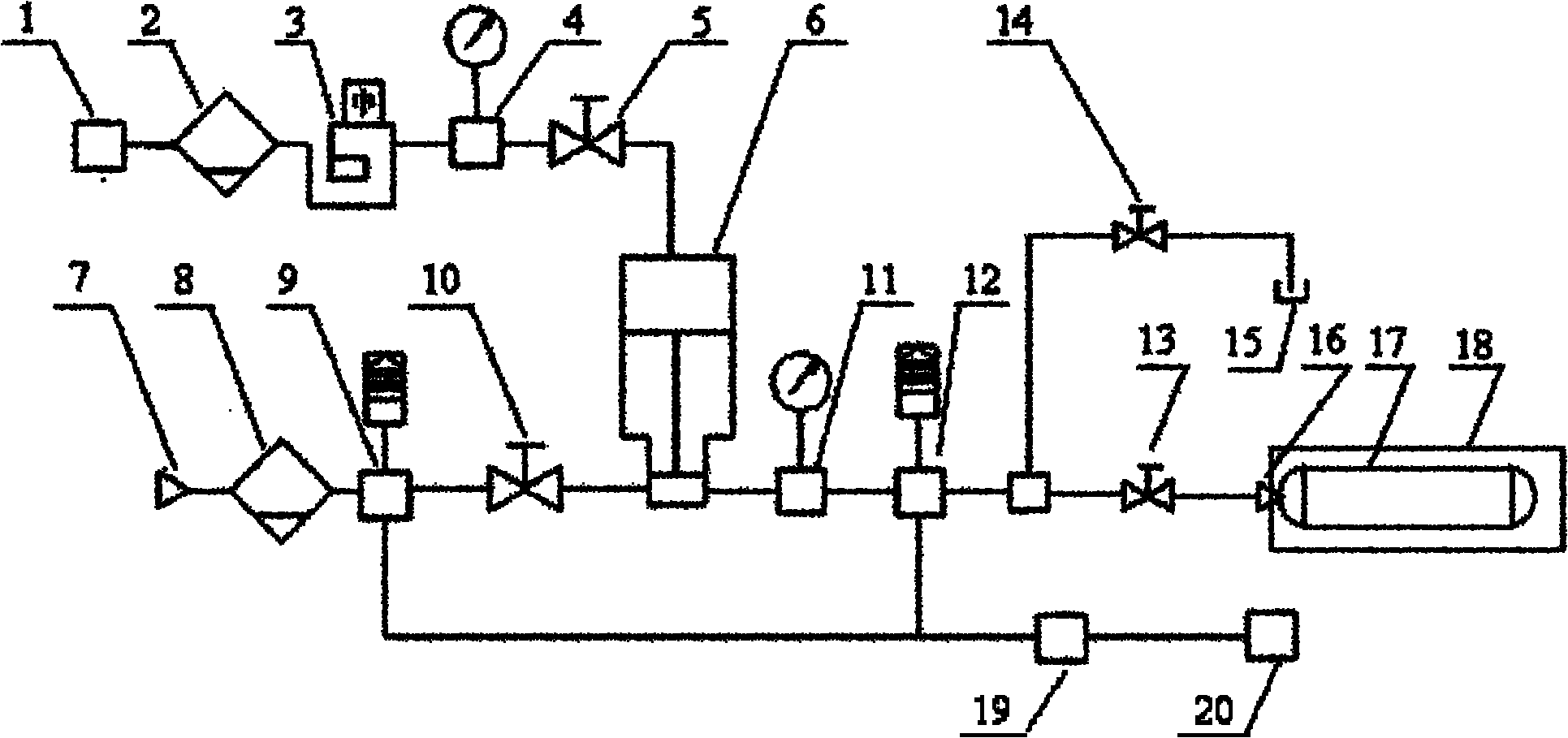

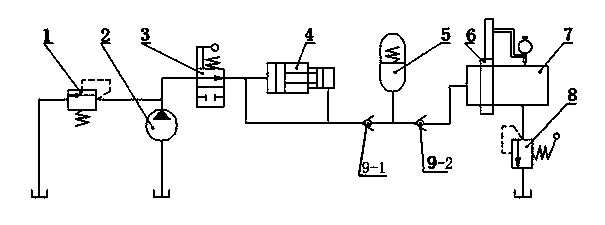

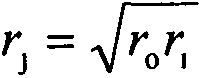

High-pressure bursting test system for pressure vessels

InactiveCN102419285AImprove securitySimple structureMaterial strength using tensile/compressive forcesEngineeringYield pressure

The invention discloses a high-pressure bursting test system for pressure vessels. The high-pressure bursting test system comprises a high-pressure bursting sample vessel, a high-pressure power source module, a vessel installing and sealing protection device module, a pressure relief device module, and a pressure / flow signal measuring and displaying module, wherein the high-pressure power source module is hermetically connected with the high-pressure bursting sample vessel by the vessel installing and sealing protection device module, the pressure / flow signal measuring and displaying module is arranged on an airflow path / liquid flow path of the high-pressure power source module, and the pressure relief device module is connected between the high-pressure power source module and the high-pressure bursting sample vessel. By using the high-pressure bursting test system for pressure vessels disclosed by the invention, a pressure-liquid feed amount change curve can be measured and recorded in real time, and through analysis on the curve, the volume expansibility, yield pressure, ultimate load, bursting pressure and safety margin of the vessel can be obtained; and the high-pressure bursting test system is high in measurement accuracy and comprehensive in data and can provide more useful information for scientific researches.

Owner:EAST CHINA UNIV OF SCI & TECH +2

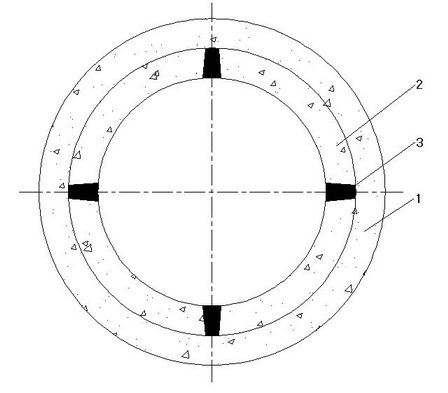

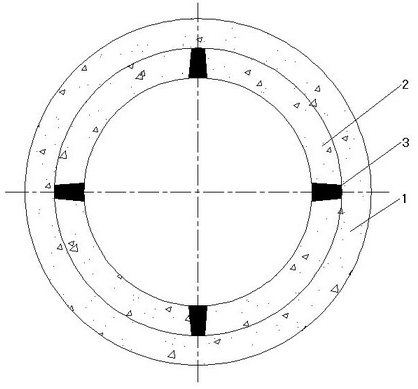

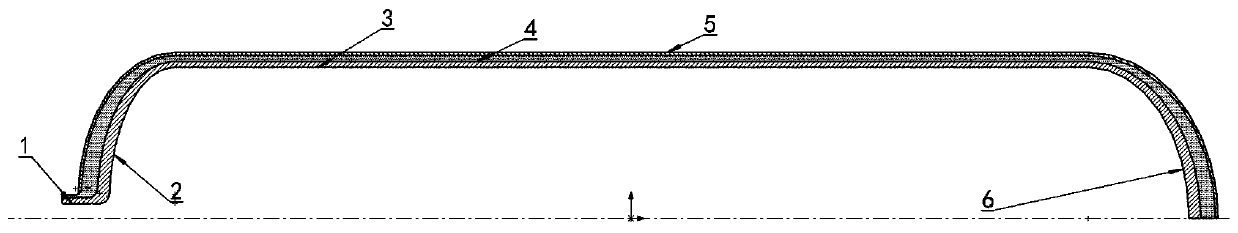

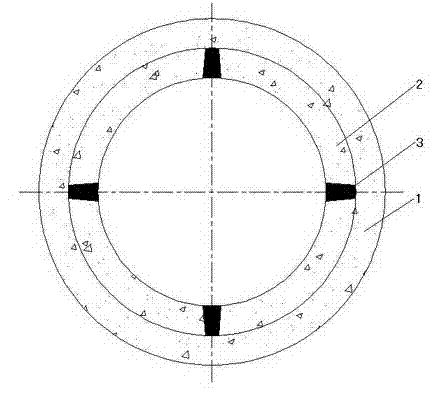

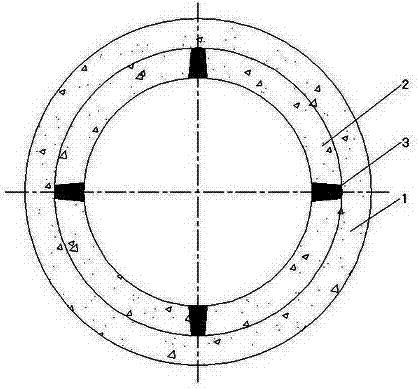

Circumferentially compressible composite well wall and construction method thereof

ActiveCN102011592AUniform radial stress distributionImprove hoop carrying capacityUnderground chambersTunnel liningStructural engineeringYield pressure

The invention provides a circumferentially compressible composite well wall and a construction method thereof which are most applicable to improving the bearing capability of a vertical well wall. The composite well wall comprises a waterproof outer well wall and a circumferentially compressible inner well wall; and the inner wall is provided with at least one compressible insulating layer. In the construction method, firstly, the waterproof outer well wall is built from top to bottom according to the section height; then the inner wall embedded with the compressible insulating layer is built from bottom to top; and finally the wall is built to the designed height according to the section height. When water and soil pressure effects surrounding the composite well wall, the compressible insulating layer of the inner well wall is compressed for yielding pressure so as to enable the stress to be distributed more evenly along the radial direction of the well wall, thus effectively improving the bearing capability of the well wall, effectively reducing the thickness of the existing well wall, improving the utilization ratio of the shaft section, and reducing the engineering cost to a large extent.

Owner:CHINA UNIV OF MINING & TECH

High oil peanut quality breeding method

InactiveCN1633840AThe technical method is simpleGood characterPlant genotype modificationMicrobiologyYield pressure

The invention provides a high oil peanut quality breeding method which comprises, combining parental generation combination by selecting seeds with good comprehensiveness and high oil content, selecting fine strains at early stage generation, which is high yield pressure screen selecting, determining oil content in each seed of the single strain, screening seeds with high oil content for cultivation on next generation, which is high oil pressure screening, finally selecting fine single strain and determining oil content for each seed of the fine single strain for different separated generations, and accomplishing high yield and high oil pressure selection and oriental cultivation.

Owner:CROP RES INST GUANGDONG ACAD OF AGRI SCI

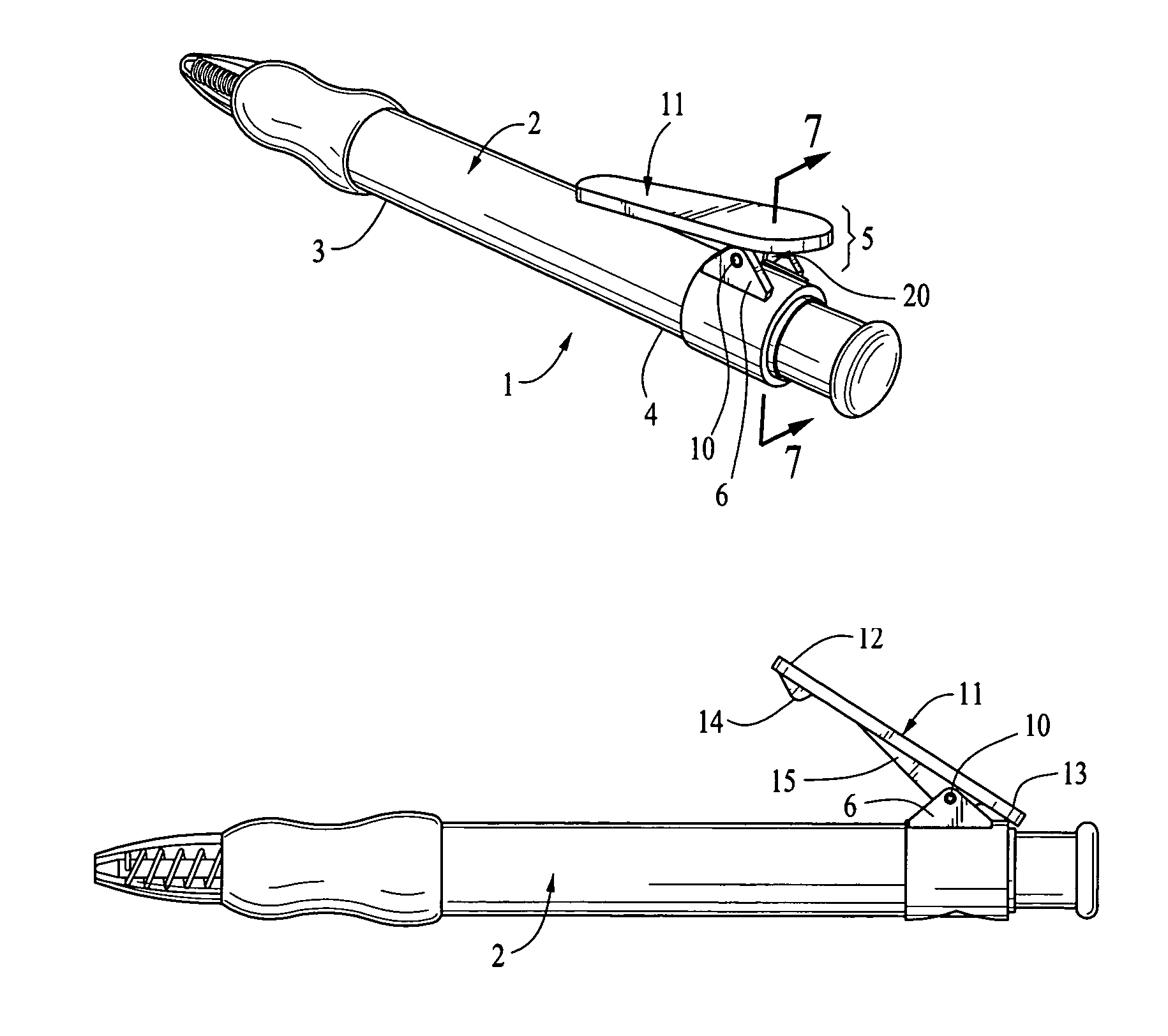

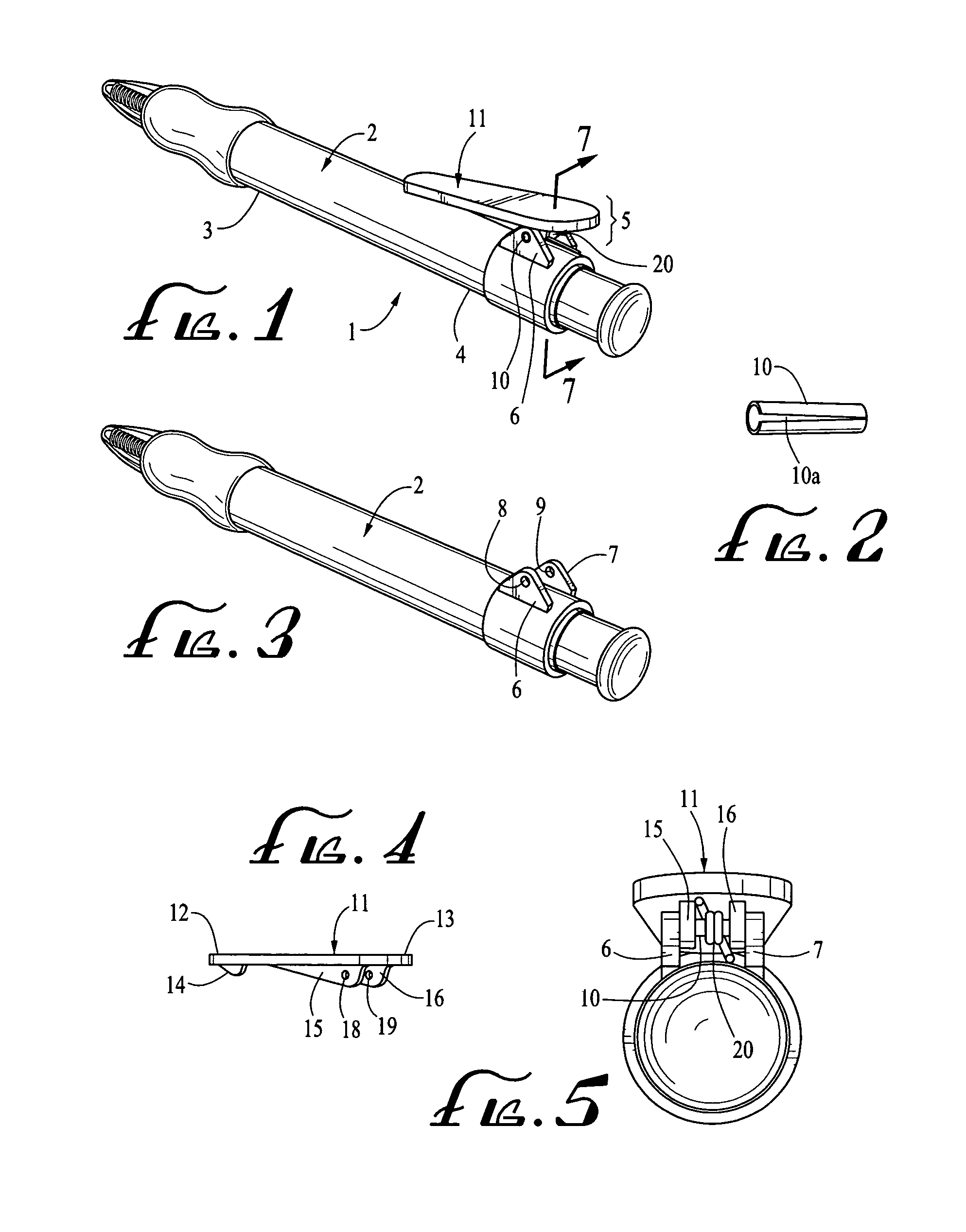

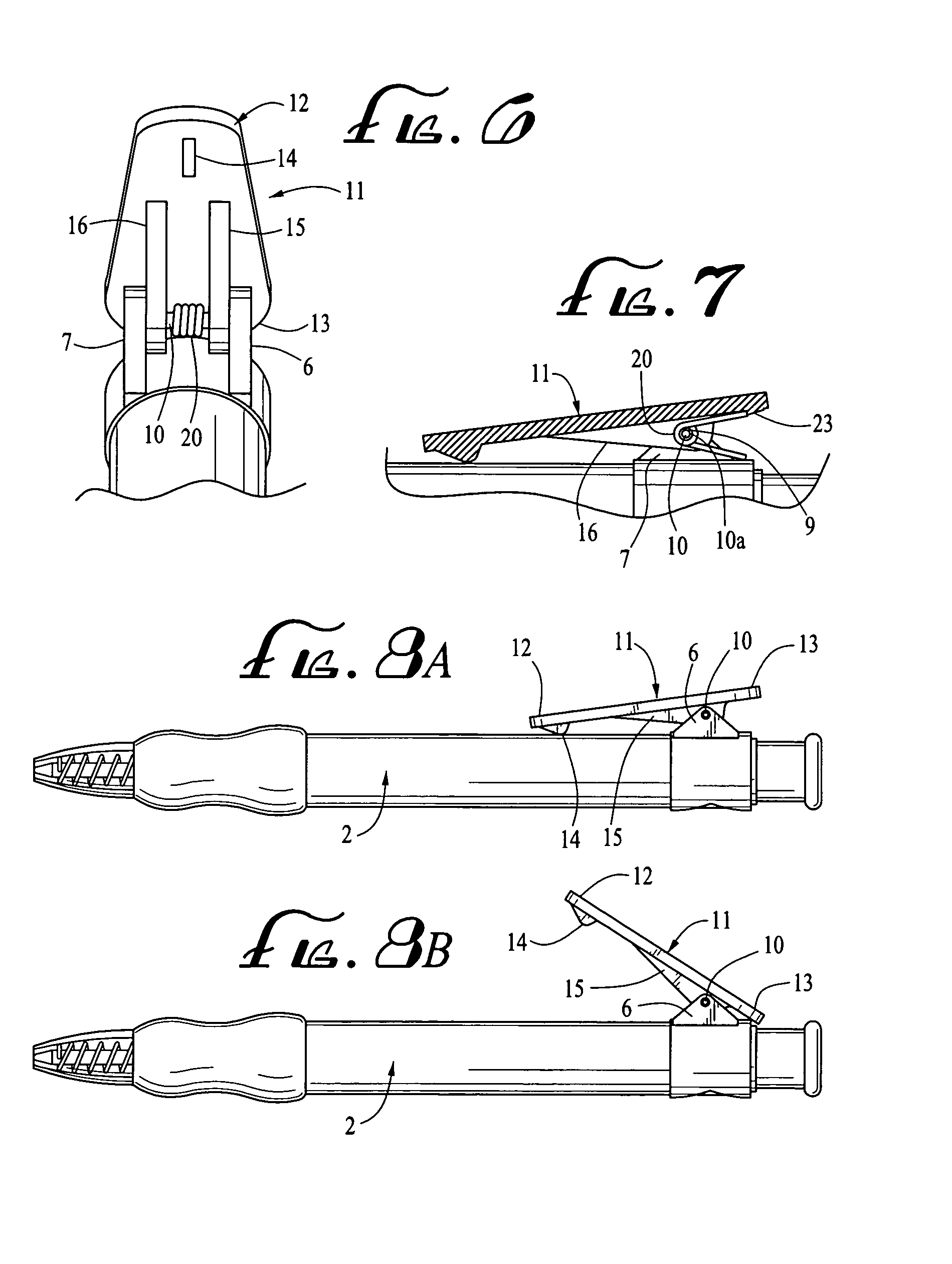

Big clip pen

InactiveUS7018123B1Increasing the thicknessHigh strengthTravelling carriersHoldersHand heldEngineering

A clip assembly securably affixable to the body of a variety of hand-held implements, including writing devices, which is capable of clasping objects substantially thicker that a garment pocket, such as notepads, books, and backpacks. The clip assembly comprises a pin securably engaged to the body of the hand-held implement, a rigid member having a first end for clasping an article, and a second end for manually operating the clip assembly, and a spring biasing the first end of the rigid member towards the body of said hand-held writing implement. The rigid member operably engages the pin in a manner that permits the rigid member to rotate relative to the body of the hand-held implement when a yielding pressure is applied to the second end of the rigid member.

Owner:COTAPAXI

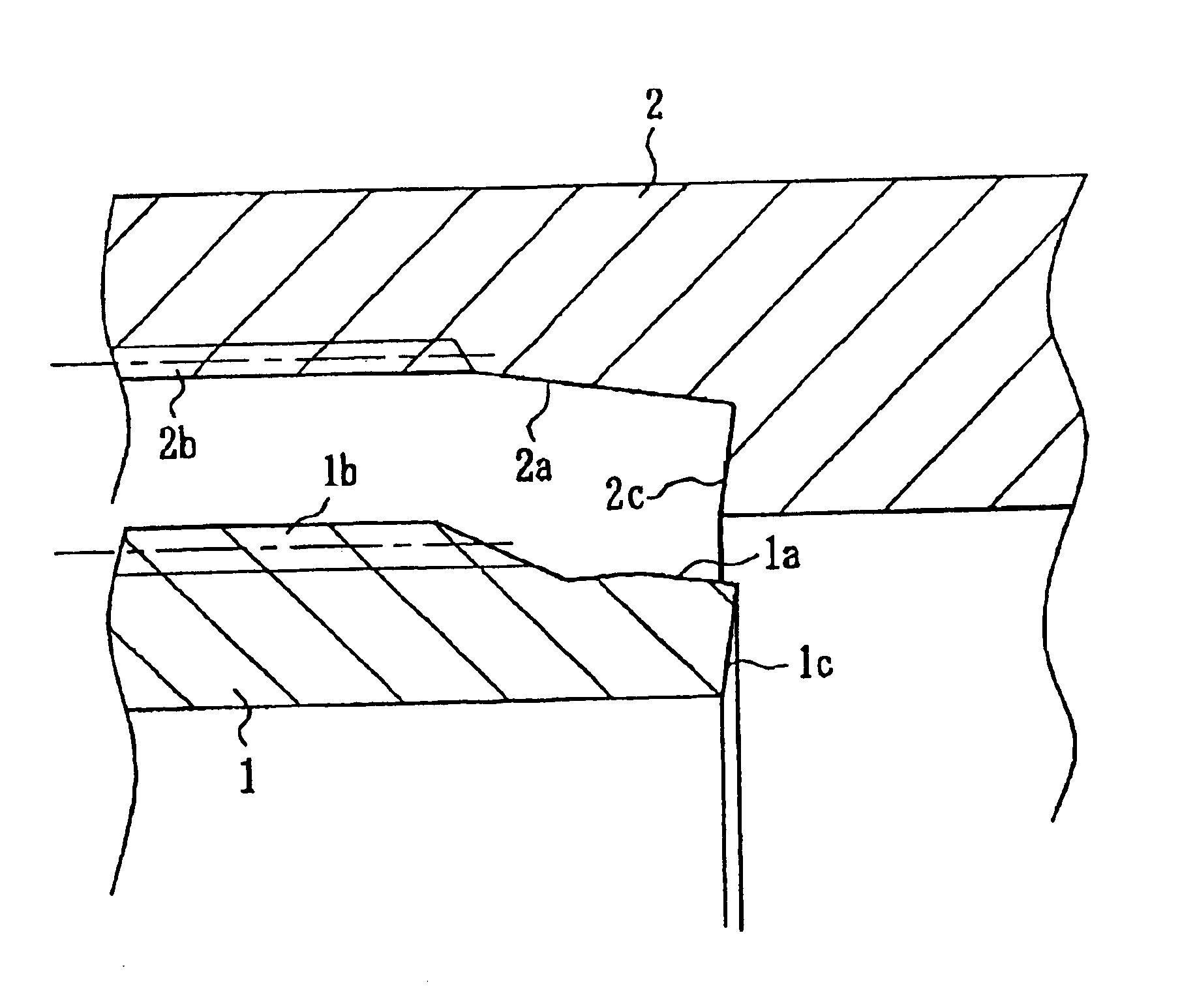

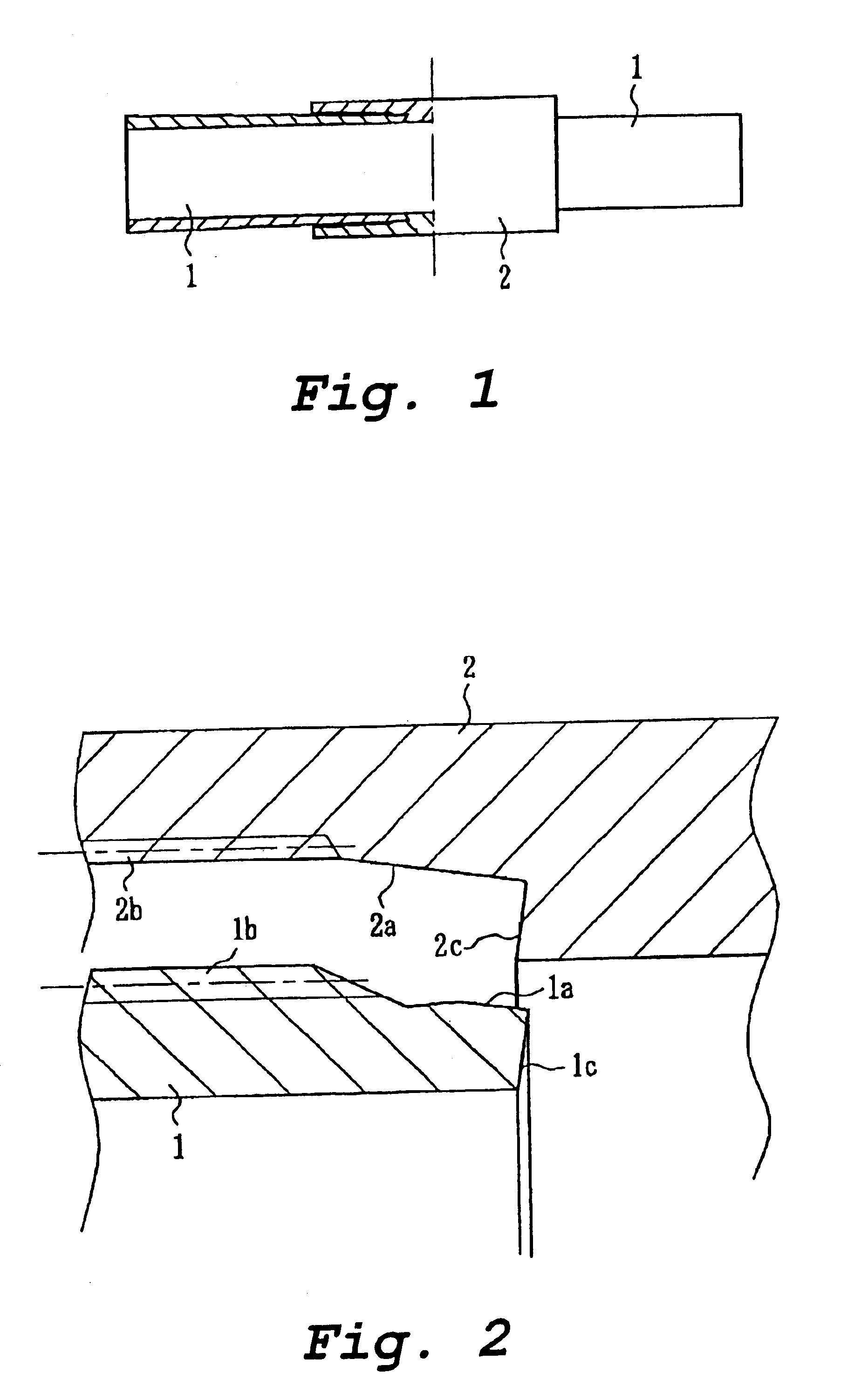

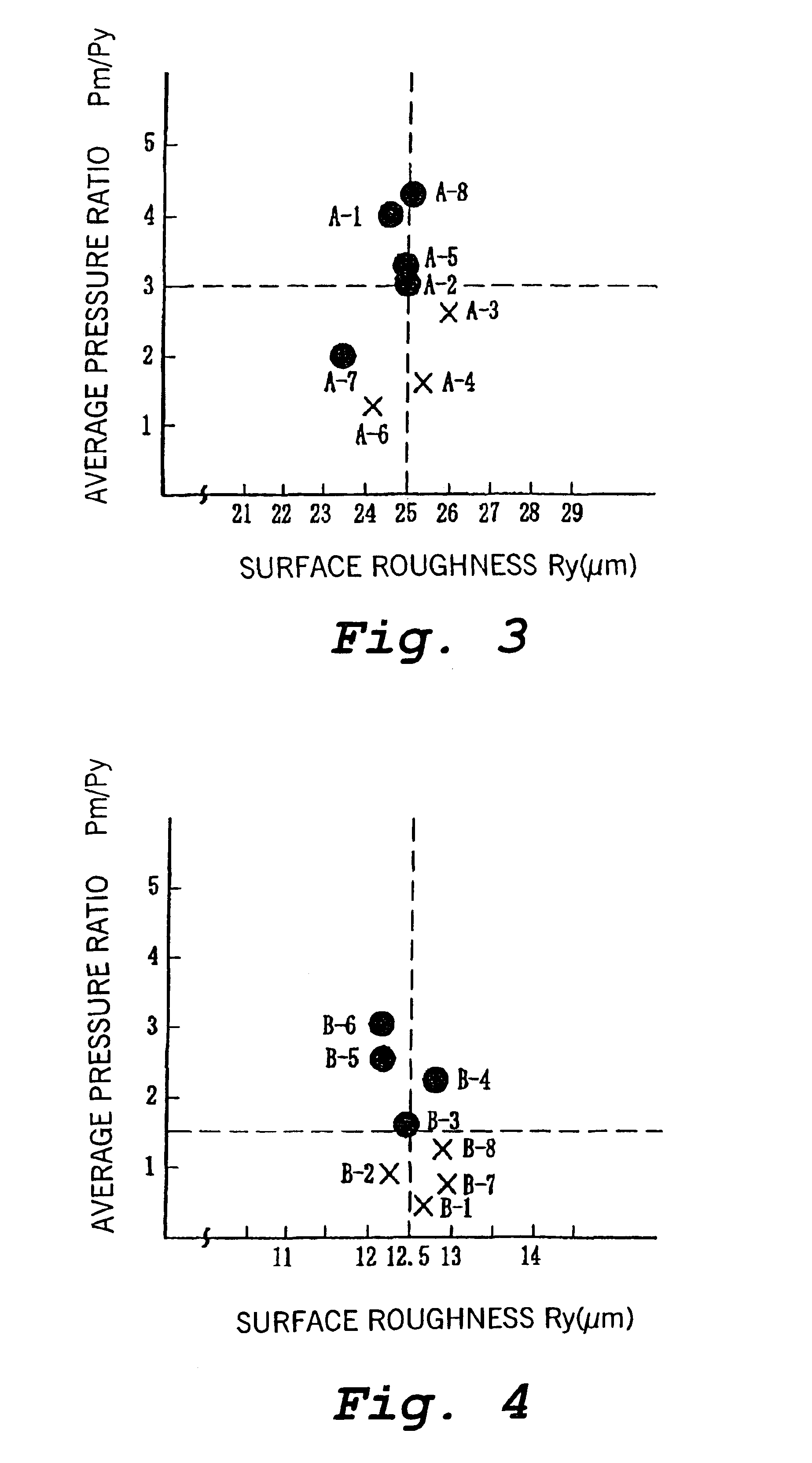

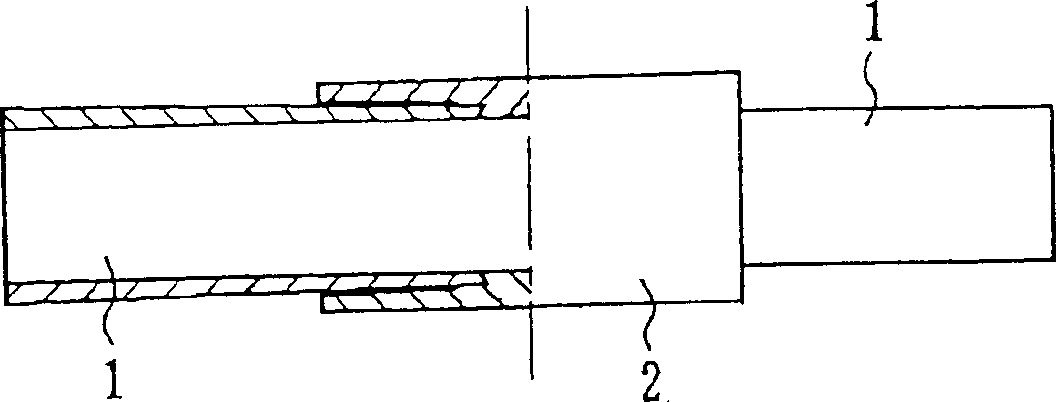

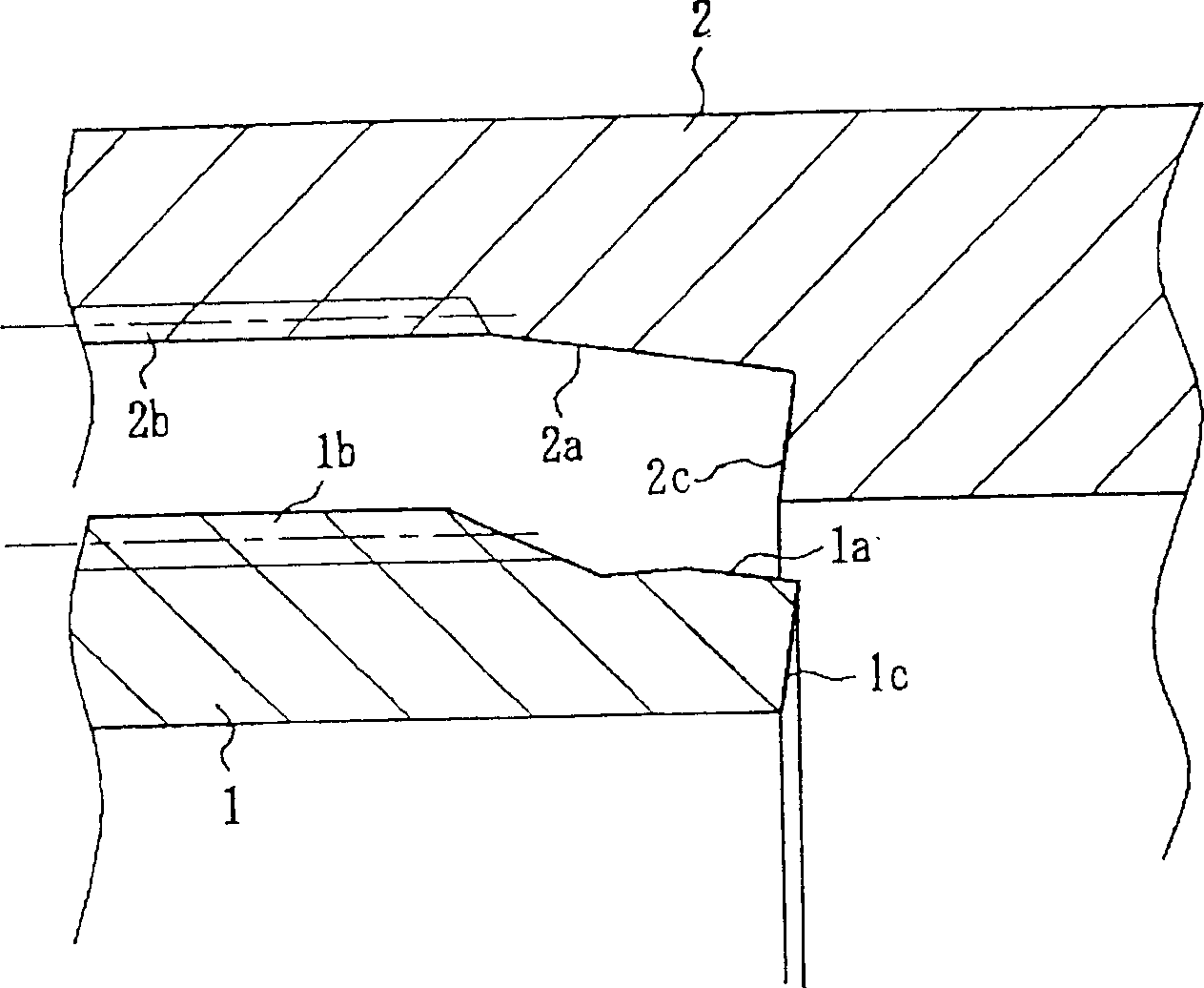

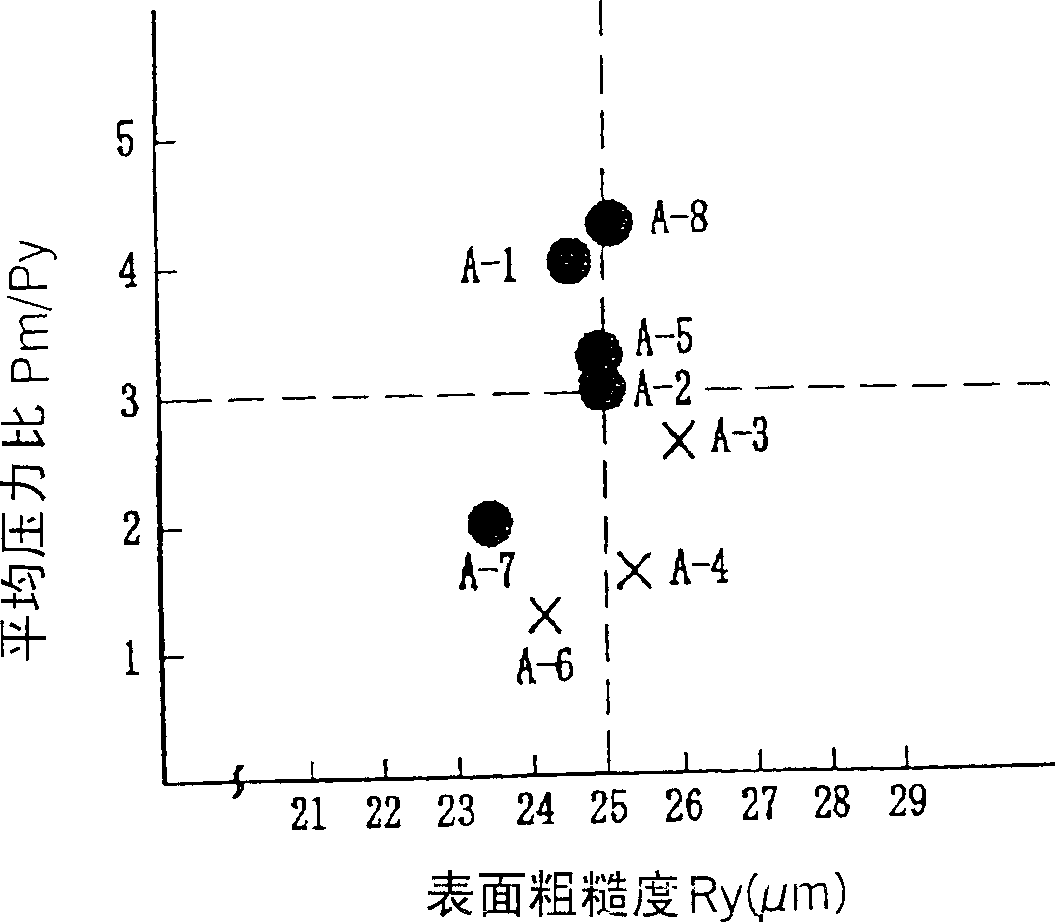

Threaded joint for pipes

A threaded joint which economically imparts effective sealing properties to a metal-to-metal seal portion and which can prevent seizing at the time of make-up comprises a steel pipe 1 having at its tip a male thread 1b and an unthreaded sealing surface 1a, and a coupling 2 having on its inner surface a female thread 2b and an unthreaded sealing surface 2a. With the yield pressure of the inner surface of the pipe being Py, (1) the average pressure Pm of the annular contact portion satisfies Pm / Py≧3, and the width in the axial direction of the portion which receives a pressure Ps which satisfies Ps / Py≧1 in the annular contact portion is at least 1 mm (or at least 2 mm), and the surface roughness Ry of both unthreaded sealing surfaces is at most 25 μm (or at most 30 μm), or (2) the relationship between the average pressure Pm of the annular contact portion and the surface roughness Ry (μm) of the unthreaded sealing surface satisfies Pm / Py≧0.0032×Ry2+1.0, and the width in the axial direction of the portion which receives a pressure Ps which satisfies Ps / Py≧1 in the annular contact portion is at least 1 mm.

Owner:NIPPON STEEL CORP +1

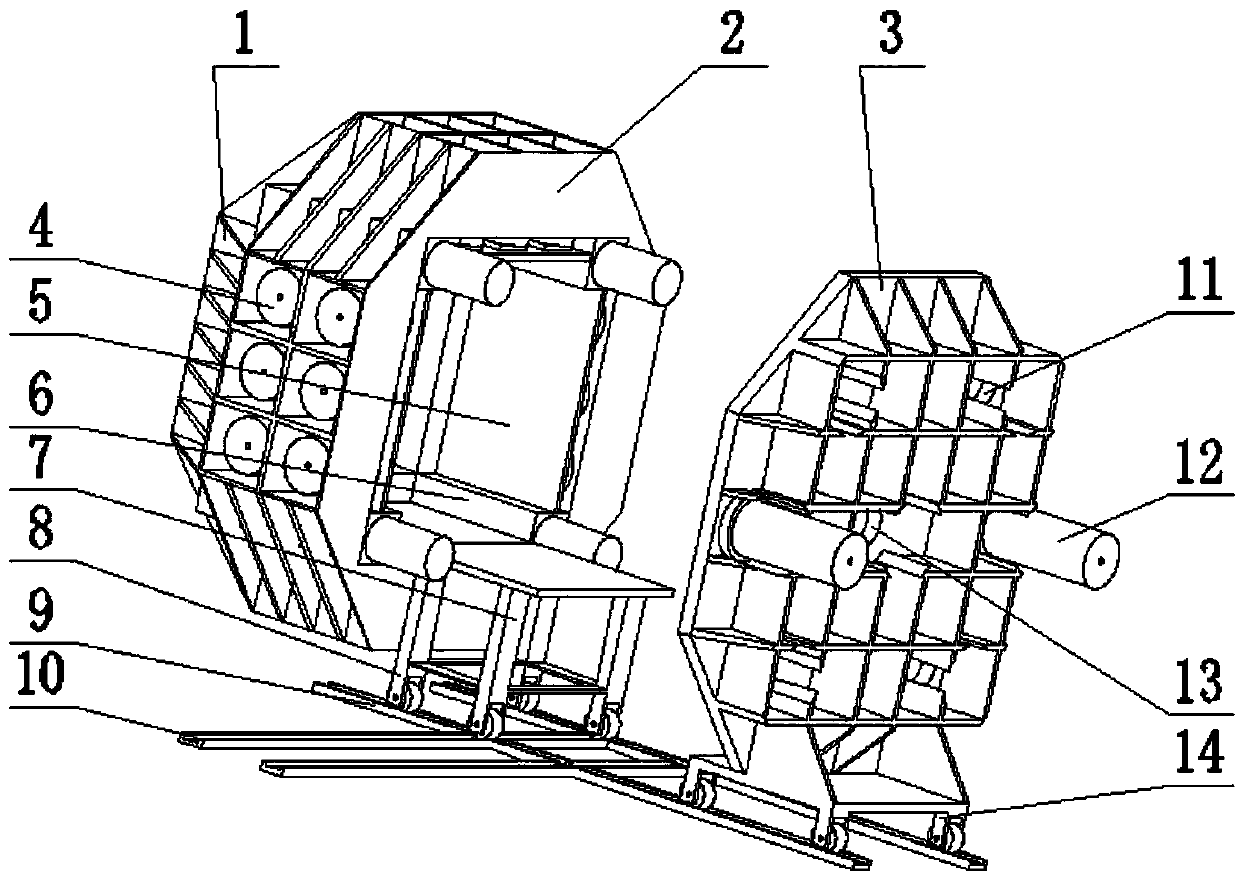

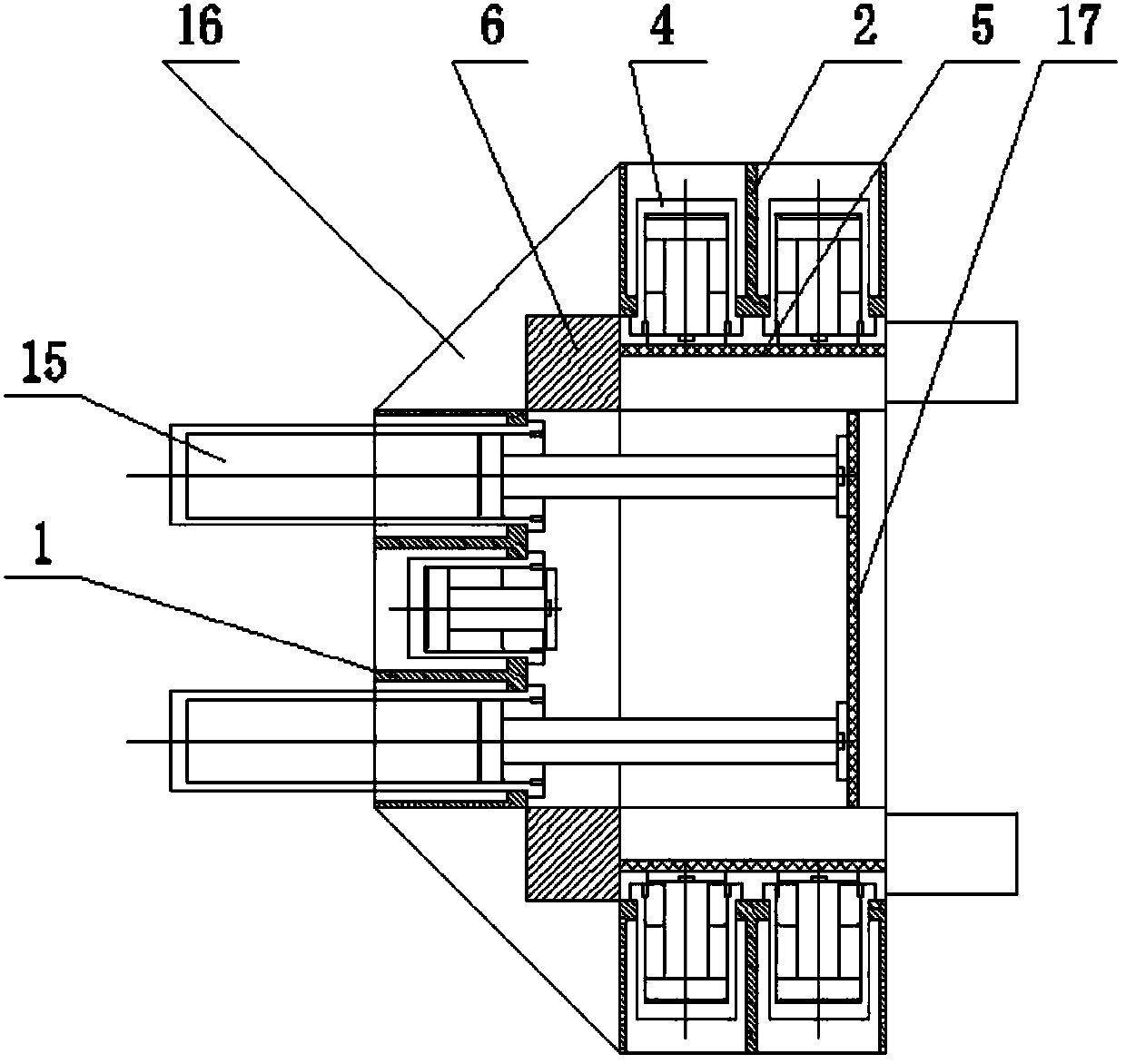

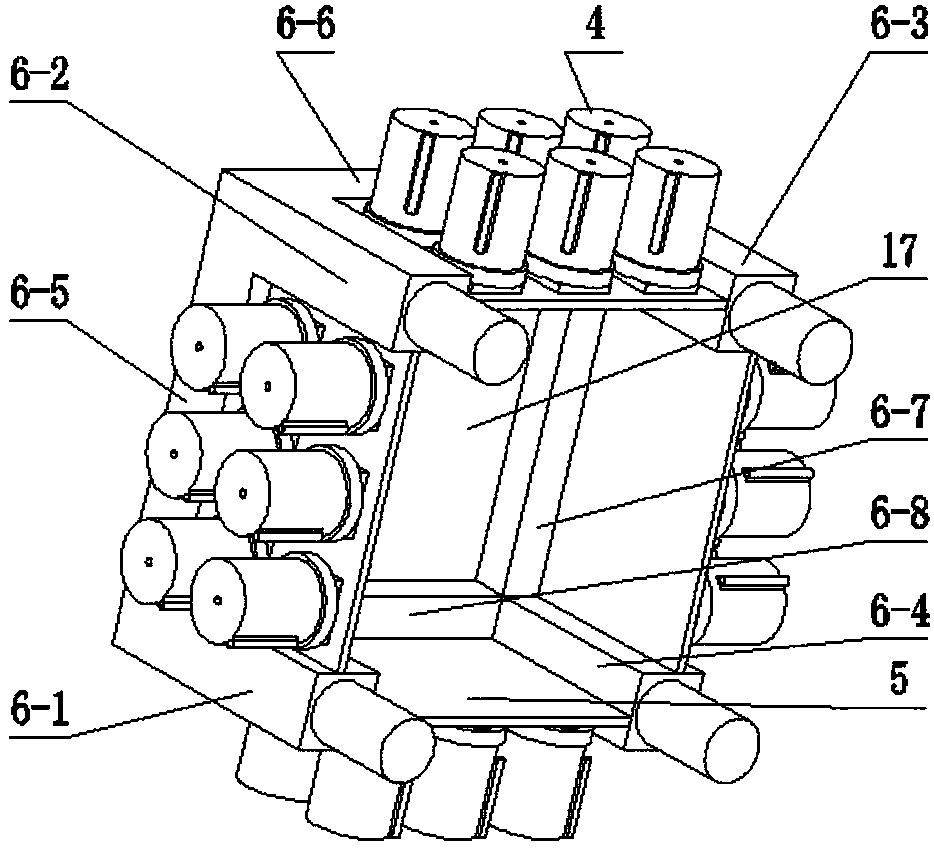

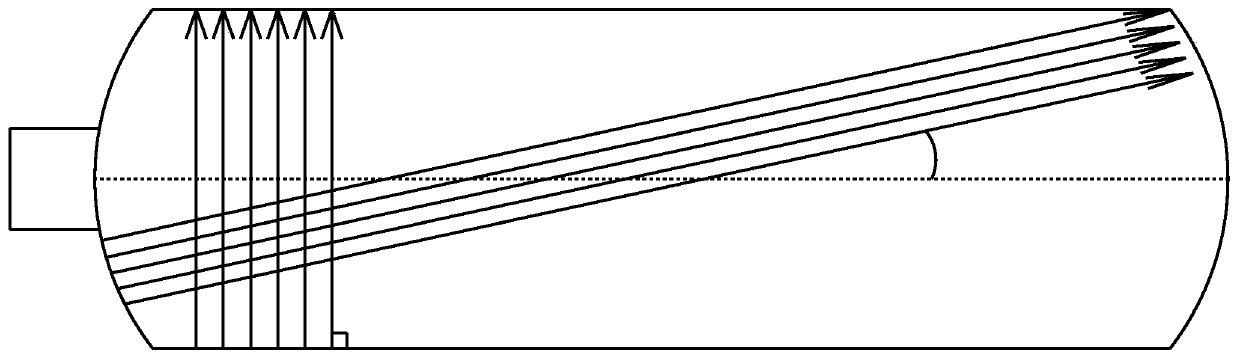

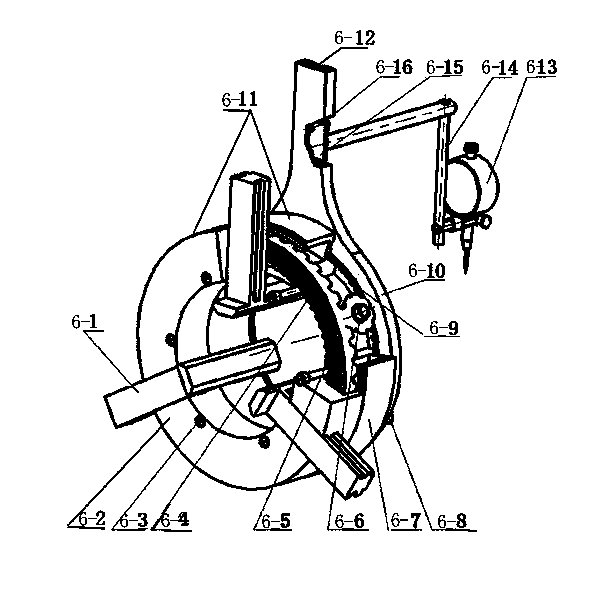

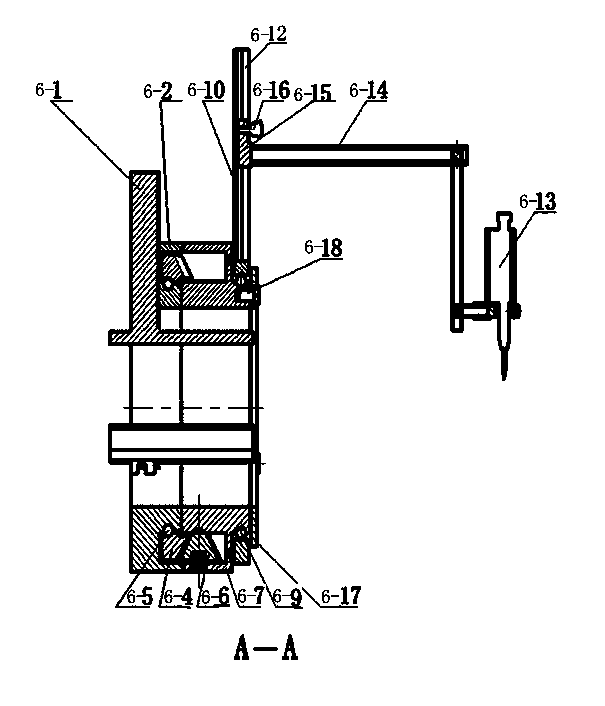

True triaxial multifunctional large deep mine laneway model testing machine

PendingCN107621415AAchieve excavationRealize monitoringMaterial strength using tensile/compressive forcesSurface stressControl system

The invention relates to a true triaxial multifunctional large deep mine laneway model testing machine, which comprises a doughnut shape-like framework system, a hydraulic loading and pressure preserving system, a control system, a pressure water system, an equipment base system and a model dismounting system. The true triaxial multifunctional large deep mine laneway model testing machine is characterized in that the doughnut shape-like framework system is a full sealing structure and can perform the true triaxial five-face and three-directional loading, provide higher model surface stress, preserve high pressure for a long time and carry out the water-yield pressure preserving test. The true triaxial multifunctional large deep mine laneway model testing machine is applicable to multiple scientific studies of the deep mine laneway, and achieve the simulation tests of mutual influences of excavation, supporting, tunneling, water inrush, and high floor pressure, and others of the underground laneway project; the testing machine has the advantages of being compact and simple in structure, convenient to operate, and environment-friendly and energy-saving.

Owner:CENT SOUTH UNIV

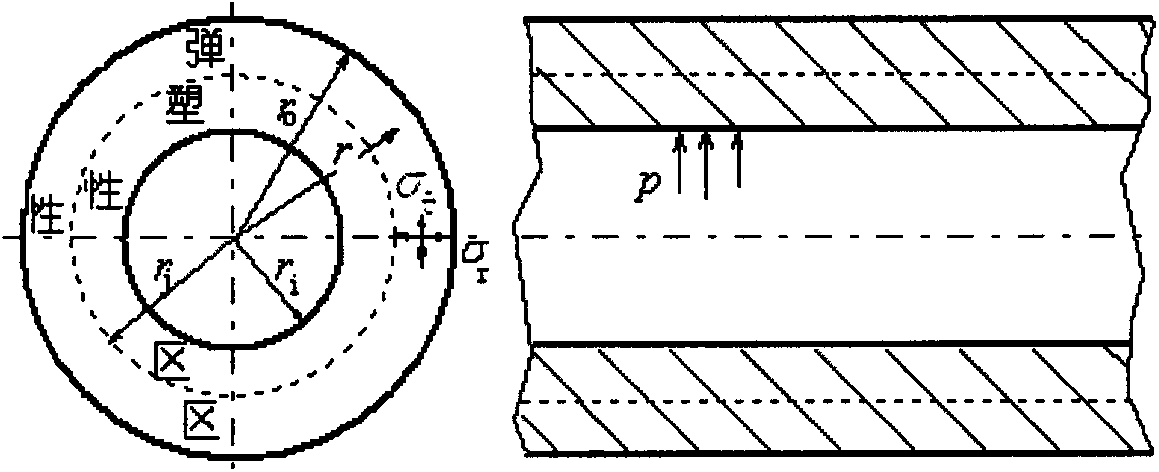

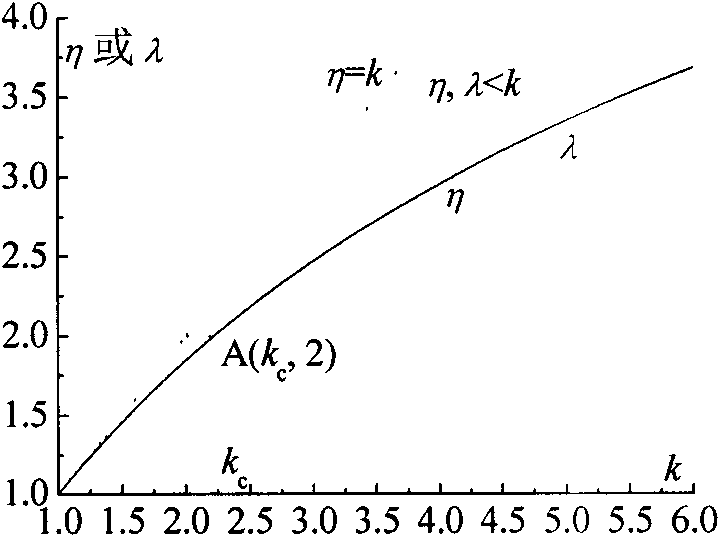

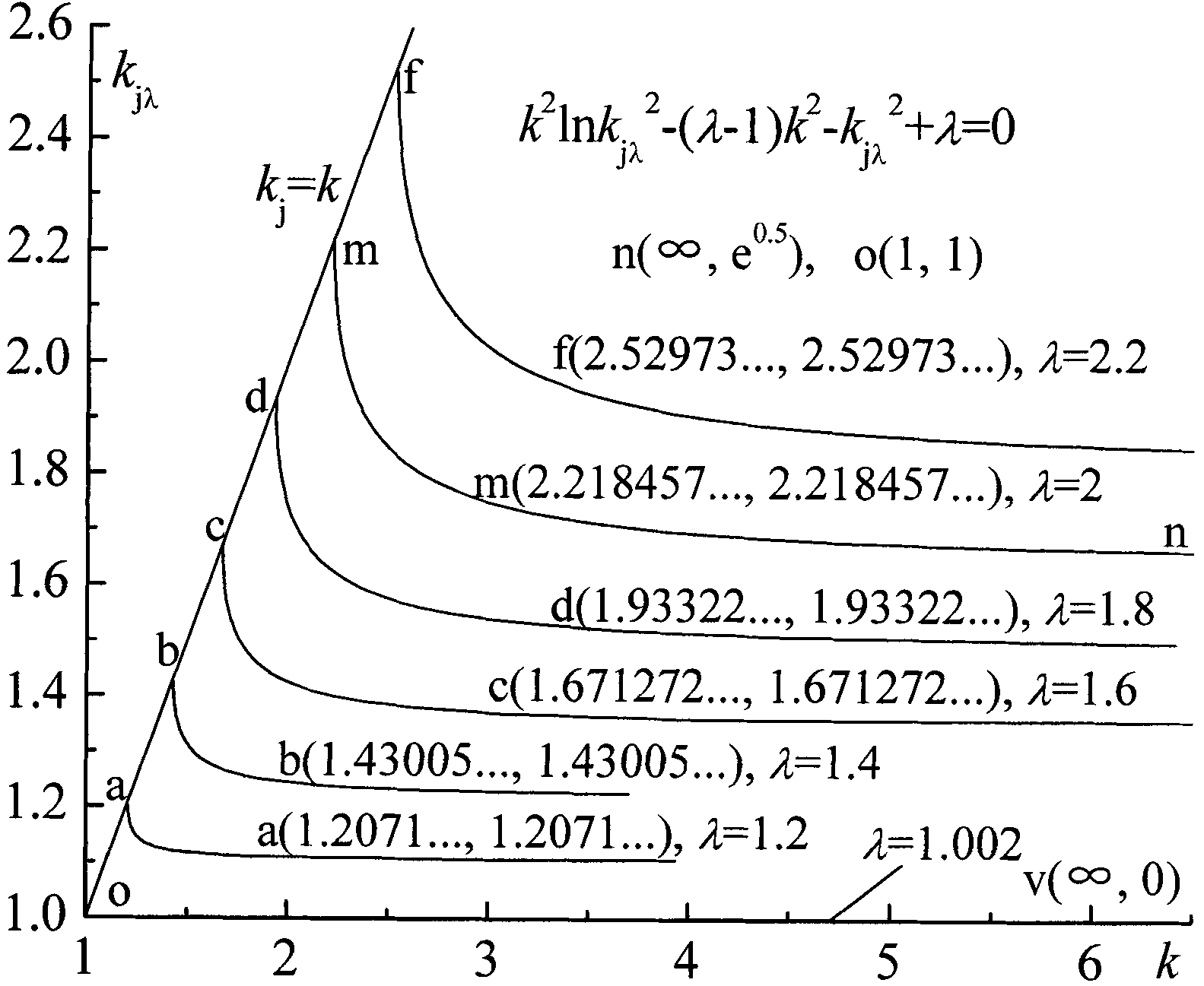

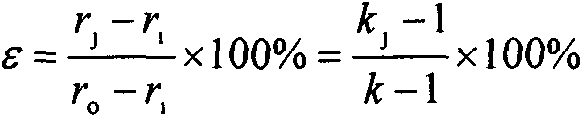

Equal-strength self-enhancement pressure vessel with variable structure size

InactiveCN103470757ASafe and reliable structureSmall overstrainPressure vesselsInternal pressureManufacturing cost reduction

The invention provides an equal-strength self-enhancement pressure vessel with the variable structure size, and aims to improve safety of the pressure vessel, reduce manufacturing cost and solve the technical problems that in the prior art, calculation is complicated and inaccurate, and a vessel is unequal in strength, fixed and unreasonable in structure, and inflexible in design. The equal-strength self-enhancement pressure vessel has the advantages that under the condition that loads are unchanged, the structure size is flexible and changeable, and the equal-strength structure is achieved (the total stress in a plastic zone is constant and the total stress of an elastic zone is constantly smaller than yield strength). According to the technical scheme, when the diameter ratio k is larger than the kc lambada value which is determined by a formula, the superstrain degree epsilon lambada of the vessel is determined according to another formula: k21n (epsilon lambada (k-1) +1) 2-(lambada -1) k2-(epsilon lambada (k-1) +1) 2 +lambada=0, and the internal pressure p of the vessel is lambada times of the initial yield load pe of a vessel with the same size and free of self-enhancement; when k is smaller than or equal to the kc lambada value which is determined by the formula, the superstrain degree of the vessel can be 100%, and in the self-enhancement pressure vessel of which maximum bearing capacity can be total yield pressure or of the structure, all the stress of the vessel is within a safety range. The diameter ratio k is the ratio of the external radius of the vessel to the internal diameter of the vessel.

Owner:HUNAN NORMAL UNIVERSITY

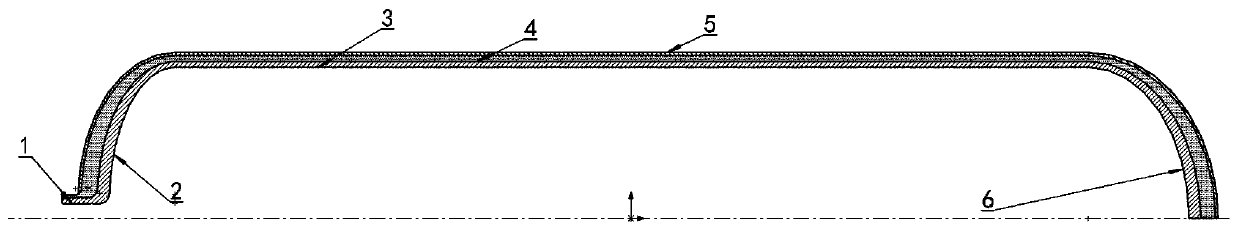

Compressed natural gas bottle with 35MPa aluminum alloy inner container fully wound with basalt fiber

PendingCN109838682AHigh compressive strengthHigh strengthPressure vesselsCompressed natural gasMetallurgy

The invention discloses a compressed natural gas bottle with a 35MPa aluminum alloy inner container fully wound with basalt fiber. The compressed natural gas bottle comprises a natural gas bottle bodywith the aluminum alloy inner container. A basalt fiber winding layer is arranged on the outer surface of the aluminum alloy inner container in a layered order in a fully winding mode, the basalt fiber winding layer comprises a circumferential winding layer winding around a aluminum alloy inner container cylinder body and a spiral winding layer winding around the aluminum alloy inner container cylinder body and heads at the two ends, and the spiral winding direction of the aluminum alloy inner container cylinder body and the heads at the two ends is consistent and continuous; and the aluminumalloy inner container is first subjected to shot blasting, and then is wound with the basalt fiber winding layer , after winding the aluminum alloy inner container, the outer surface of the basalt fiber winding layer is coated with a protective layer, and the protective layer is bisphenol A epoxy resin. The natural gas bottle can increase the working pressure of a CNG bottle for the vehicle to 35MPa, the utilization rate of the gas storage can be improved, the driving range of CNG vehicles is increased to reach the same mileage as gasoline vehicles, the strength of the aluminum alloy inner container is strengthened, and the anti-pressure ability, yield pressure, burst pressure and anti-fatigue ability of the natural gas bottle are improved.

Owner:XIHUA UNIV

Breeding method for high protein peanut

InactiveCN101204138AGood characterImprove breeding efficiencyPlant genotype modificationAngiosperms/flowering plantsSocial benefitsAgricultural science

The invention discloses a method for breeding high-protein peanut quality, which selects germplasm materials with good comprehensive characters and high-protein content to assemble parental combination; single plant with good comprehensive character is selected by breeding goal in early segregation generation, which is a high-yield pressure screening; the single plant with good comprehensive character is selected by the same standard in different segregation generation and the protein content of each single plant with good comprehensive character is measured; stable high-protein variety or strain with good comprehensive character is acquired through double pressure selection of multi-generation high-yield and high protein as well as directional breeding. The method for breeding high-protein peanut quality can carry out direct selection of protein content character; the invention is characterized by short breeding period, little blindness and high breeding efficiency. Peanut variety with high-protein content and good comprehensive character can be bred, which has good economic and social benefit.

Owner:CROP RES INST GUANGDONG ACAD OF AGRI SCI

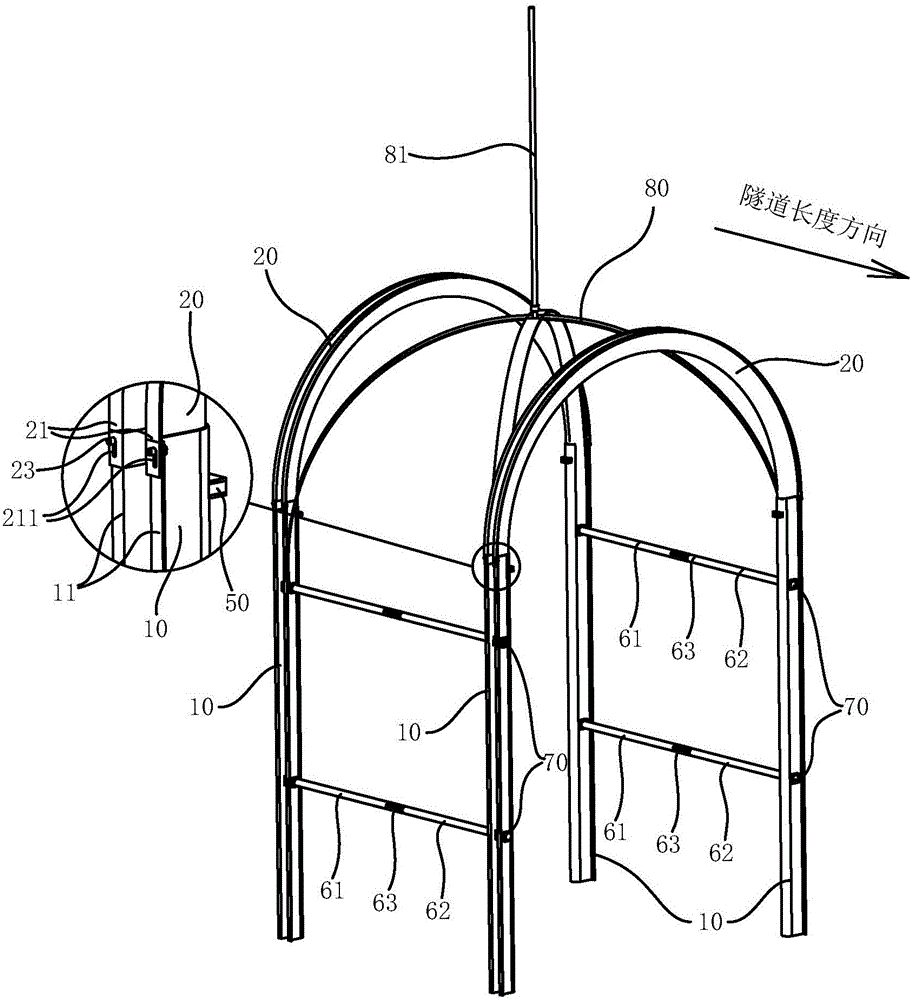

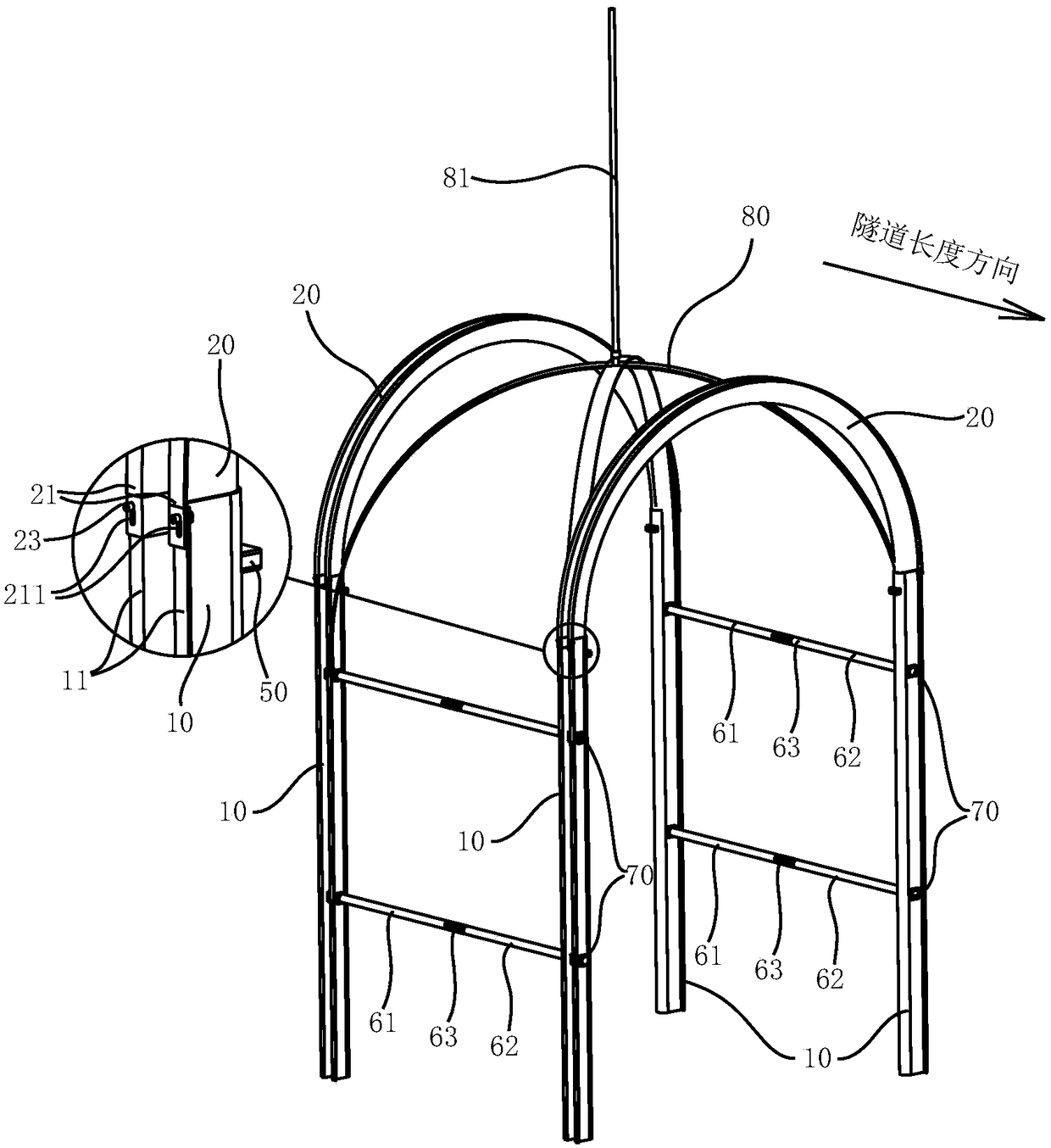

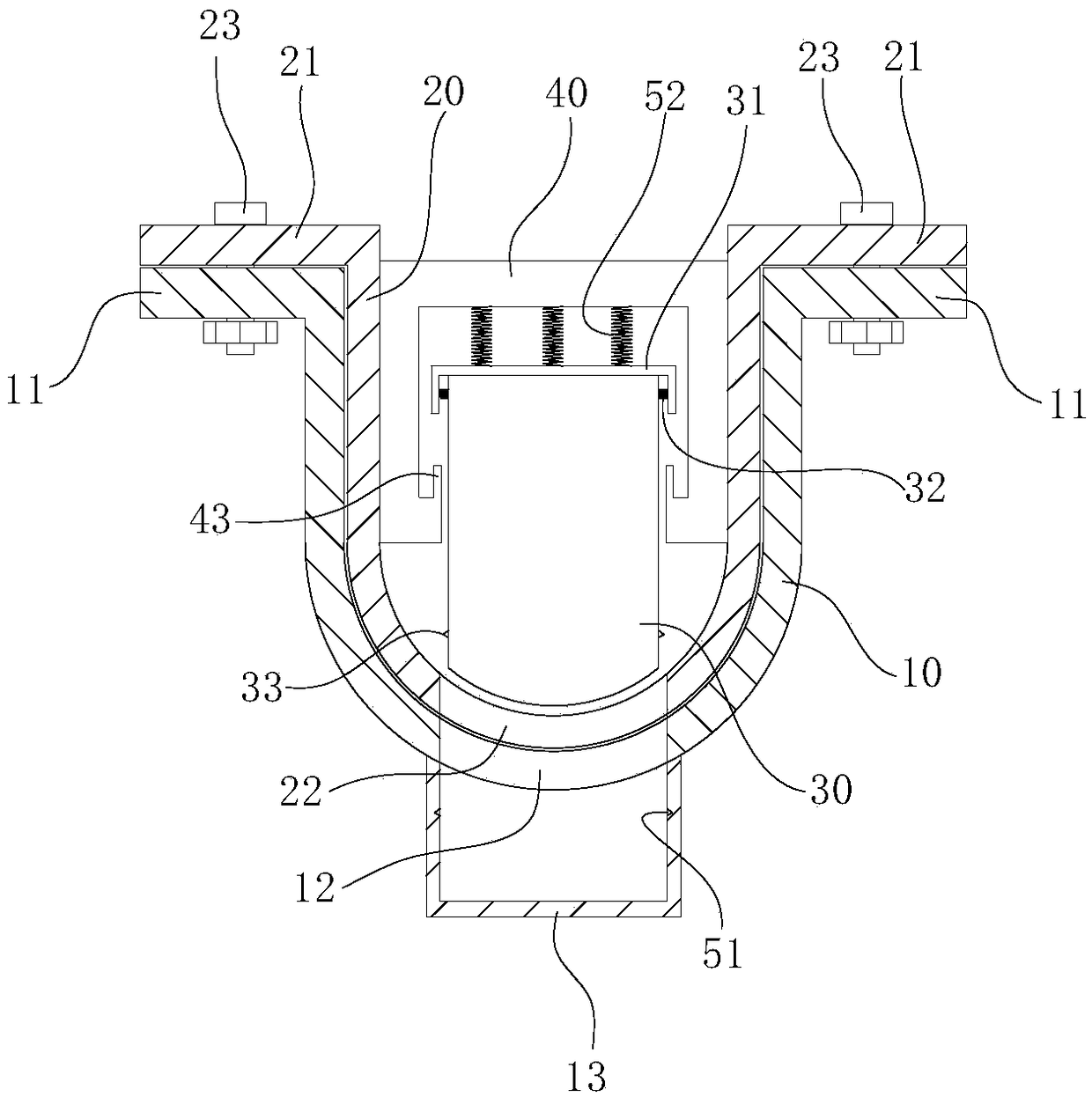

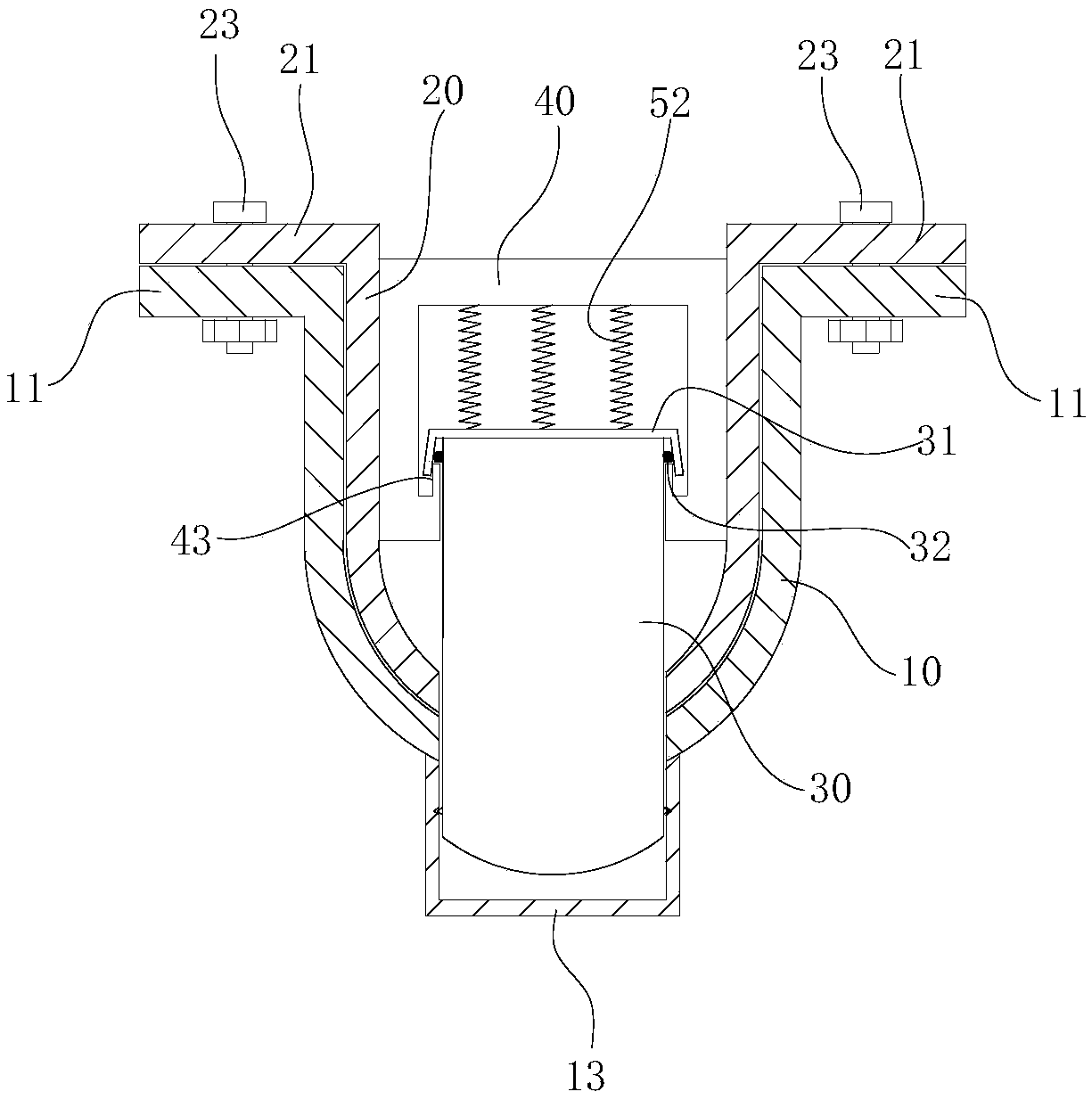

Reinforced yielding U-shaped steel bracket

ActiveCN106812544APrevent bucklingAvoid kickingUnderground chambersTunnel liningStructural engineeringEngineering

The invention relates to a reinforced yielding U-shaped steel bracket which comprises first support section steel vertically arranged on two sides of a roadway, wherein second support section steel for supporting surrounding rocks at the cambered top of the roadway is arranged at the upper ends of the first support section steel, and is bent into a curved structure; two ends of the second support section steel are movably matched with the upper ends of the first support section steel in the vertical direction respectively; slip limiting yielding mechanisms for stopping the second support section steel moving downwards are arranged at the overlapping parts of the first and second support section steel. Such yielding U-shaped steel brackets can be arranged at intervals in the length direction of the roadway, and the pressure of the surrounding rocks at the top of the roadway is released and transmitted to the second support section steel, so that a sufficient yielding amount is provided for the surrounding rocks at the top of the roadway to avoid the condition that the U-shaped steel brackets reach the yield strength to cause buckling, kicking and collapsing of the U-shaped steel brackets, and further ensure effective support to the surrounding rocks at the cambered top of the roadway, and yielding pressure release and rigid support of the surrounding rocks at the cambered top of the roadway are realized.

Owner:ANHUI UNIV OF SCI & TECH

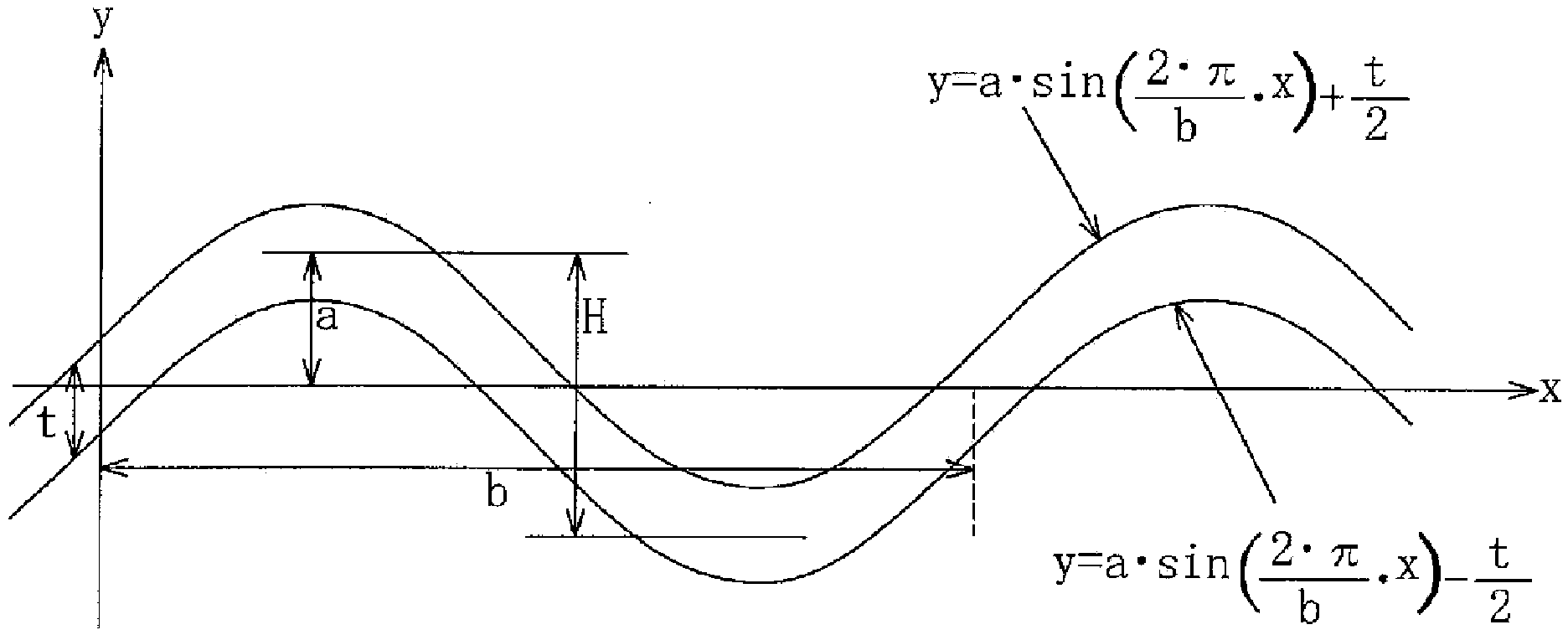

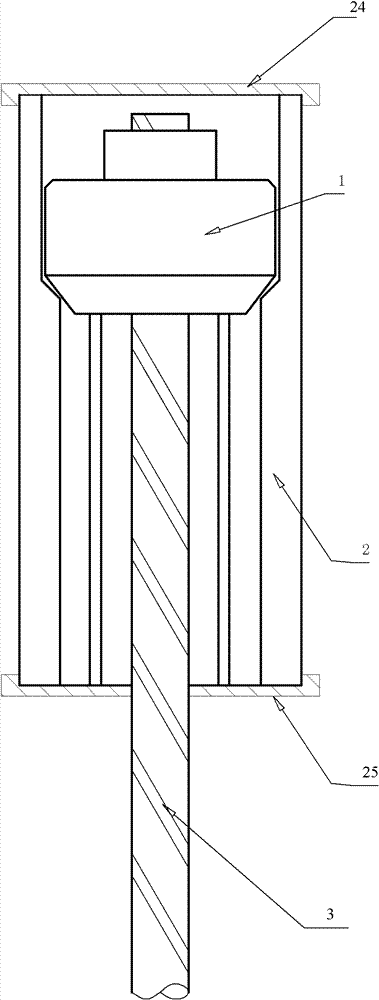

Method and device for measuring yield limit of super-high pressure thick-wall cylinder

InactiveCN103411836AAchieve regulationRealize fixed-point measurementMaterial strength using tensile/compressive forcesUltra high voltageEngineering

According to the regularities of distribution of stress-strain of a super-high pressure thick-wall cylinder and characteristics of a plastic layer and an elastic layer of the cylinder, a static super-high pressure value provided by a hydraulic system thick wall cylinder is increased by equal step, and is loaded inside the cylinder to be measured; and an initial yield pressure of the super-high pressure cylinder is determined according to whether strain of the unloaded cylinder changes. Therefore, the invention provides an efficient quick method and a device for measurement of yield limit of the super-high pressure thick-wall cylinder.

Owner:GUILIN UNIV OF ELECTRONIC TECH

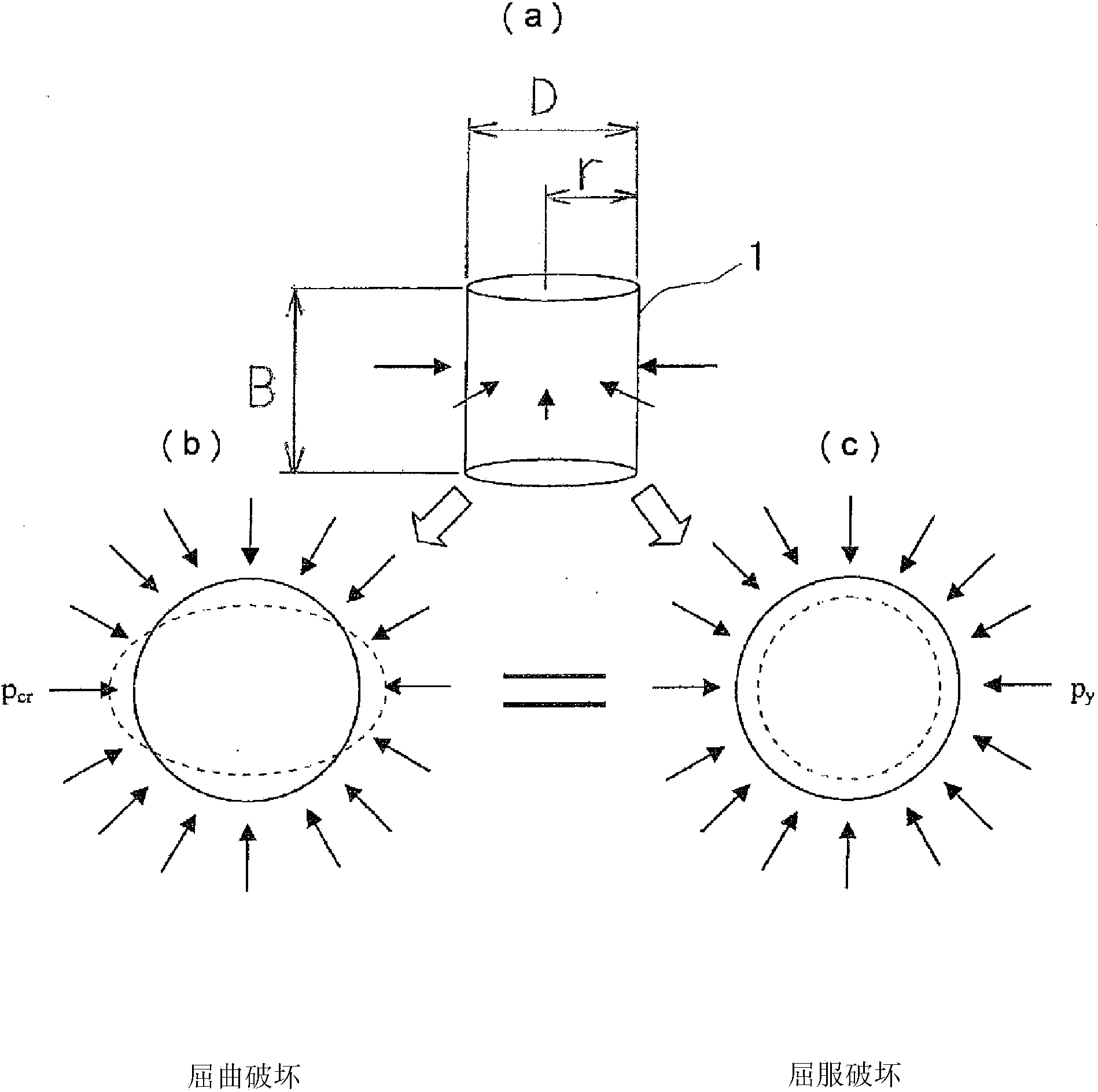

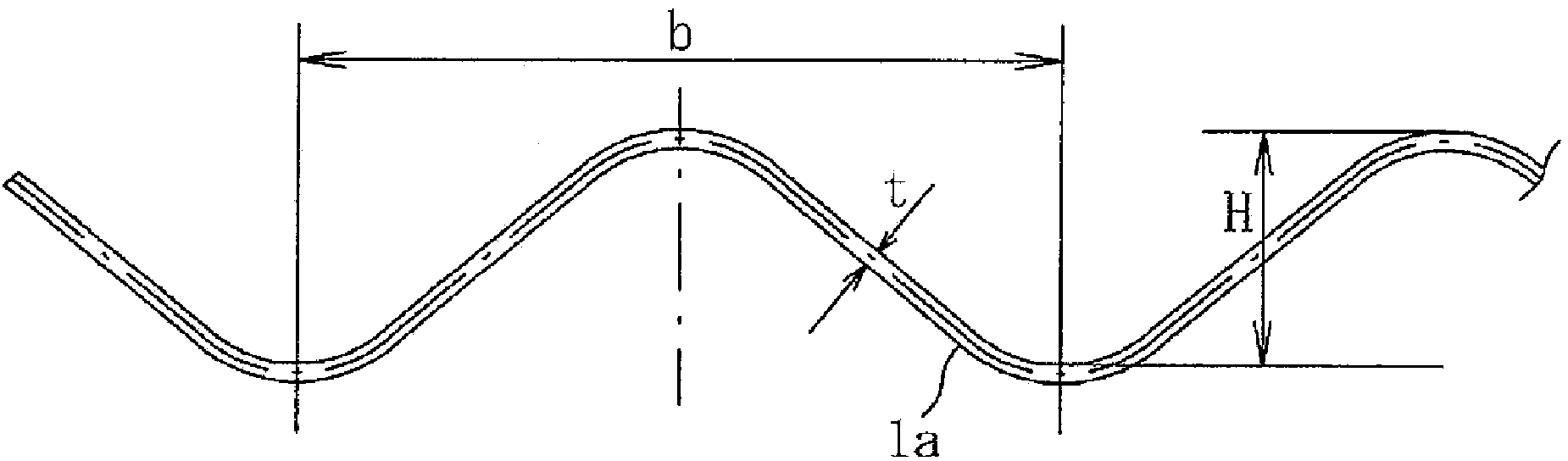

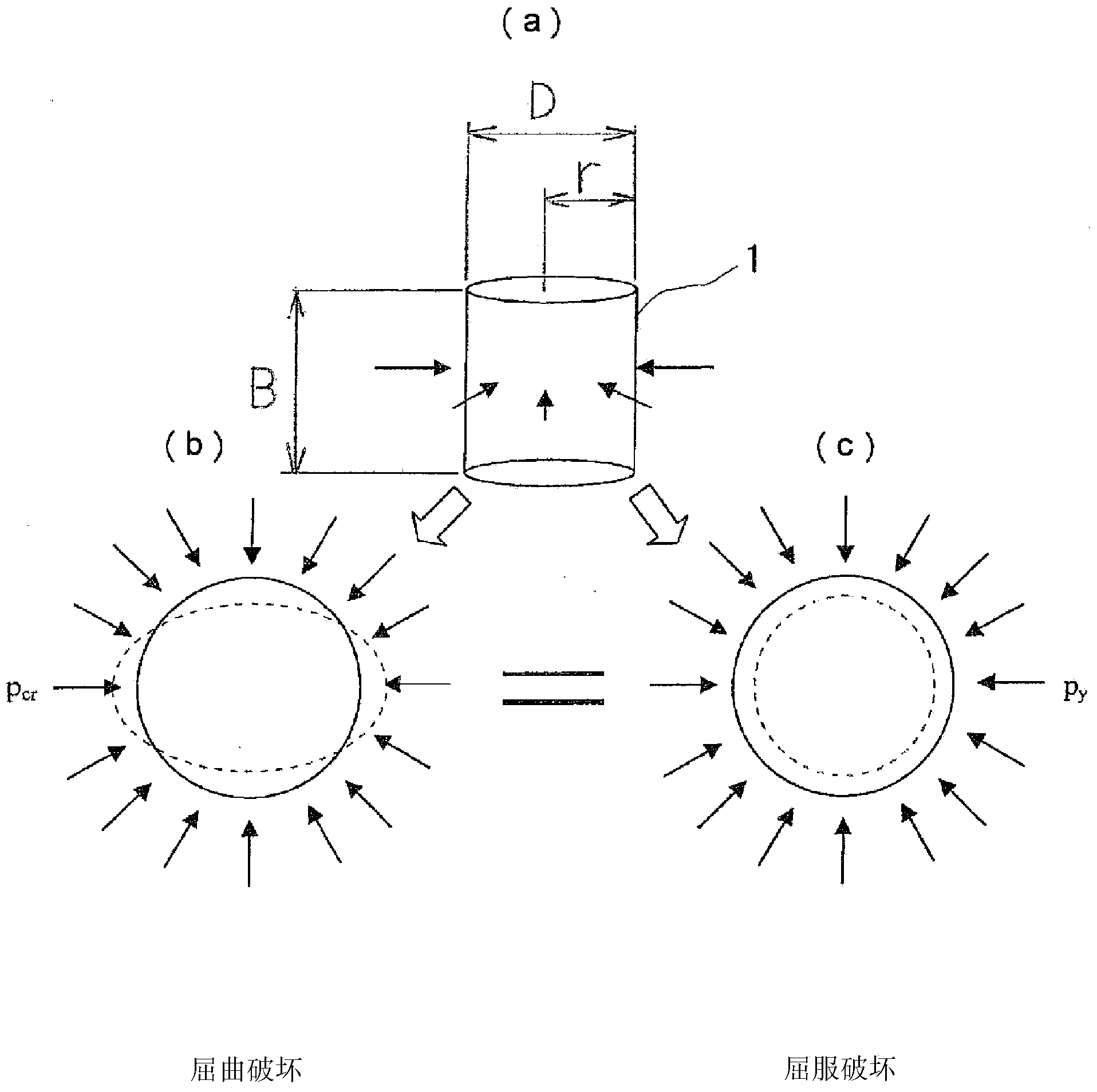

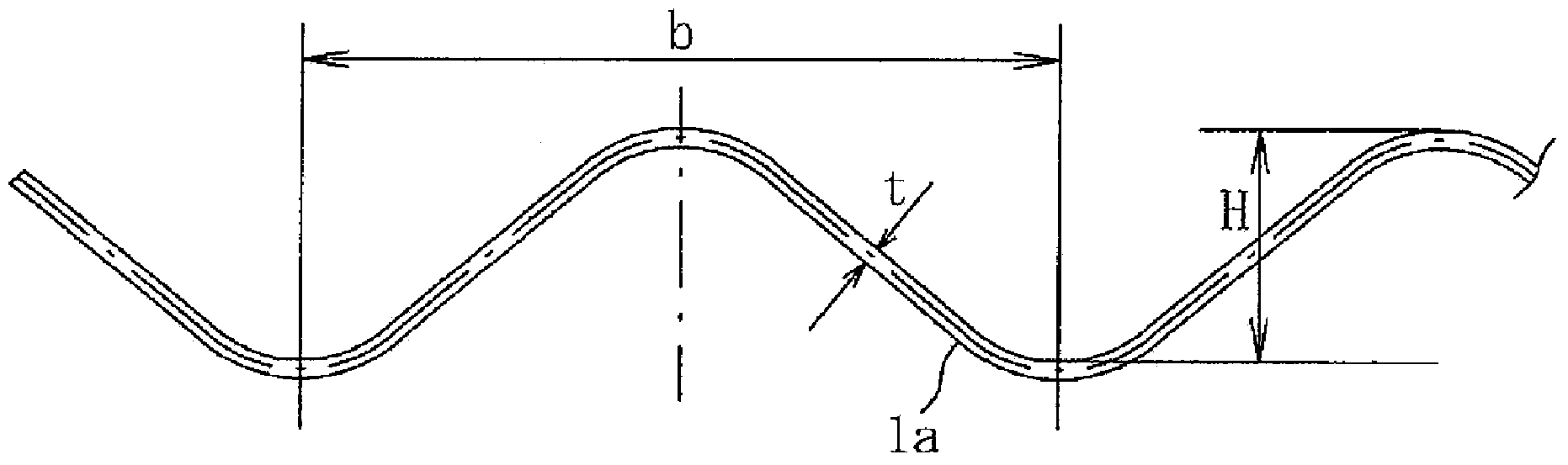

Method for designing corrugated steel sheet, and corrugated steel sheet pipe

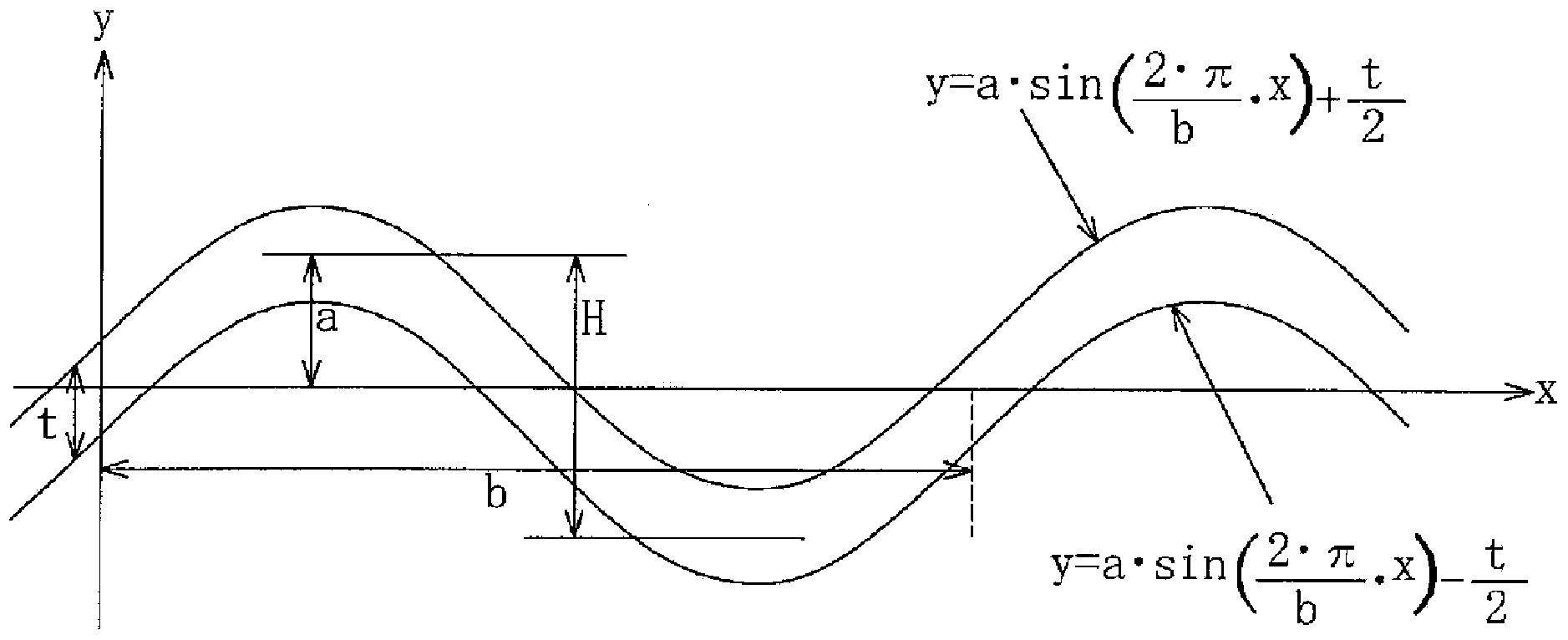

Provided is a method that is for designing a corrugated steel sheet and that is characterized by, when designing the corrugated shape of a corrugated steel sheet that configures a corrugated steel sheet pipe of tube diameter D comprising a corrugated steel sheet having corrugations having a wave depth of H, setting the wave depth (H) with respect to the tube diameter (D) in a manner so that, with the presumption that the corrugated steel sheet pipe will incur uniform external pressure at the outer surface, the annular buckling pressure (pcr) when the corrugated steel sheet pipe buckles and the yielding pressure (py) when the corrugated steel sheet pipe yields are equivalent.

Owner:NIPPON STEEL & SUMIKIN METAL PROD CO LTD

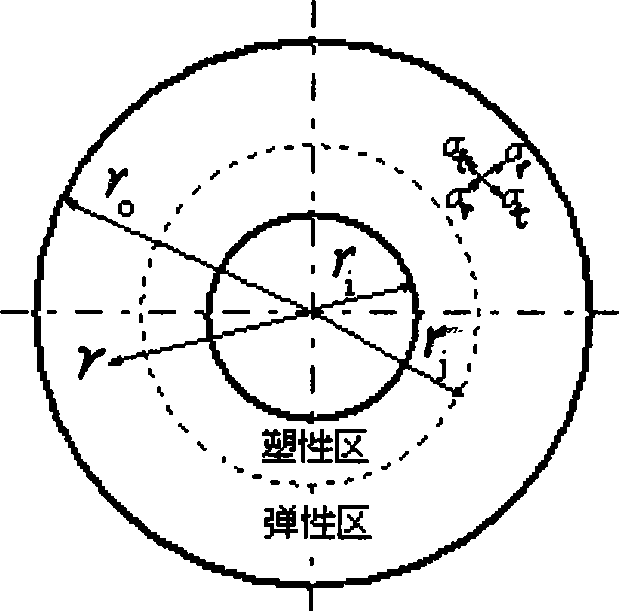

Safe self-reinforcing pressure vessel

InactiveCN101338817BAvoid cumbersomeImprove carrying capacityPressure vesselsInternal pressureSelf reinforced

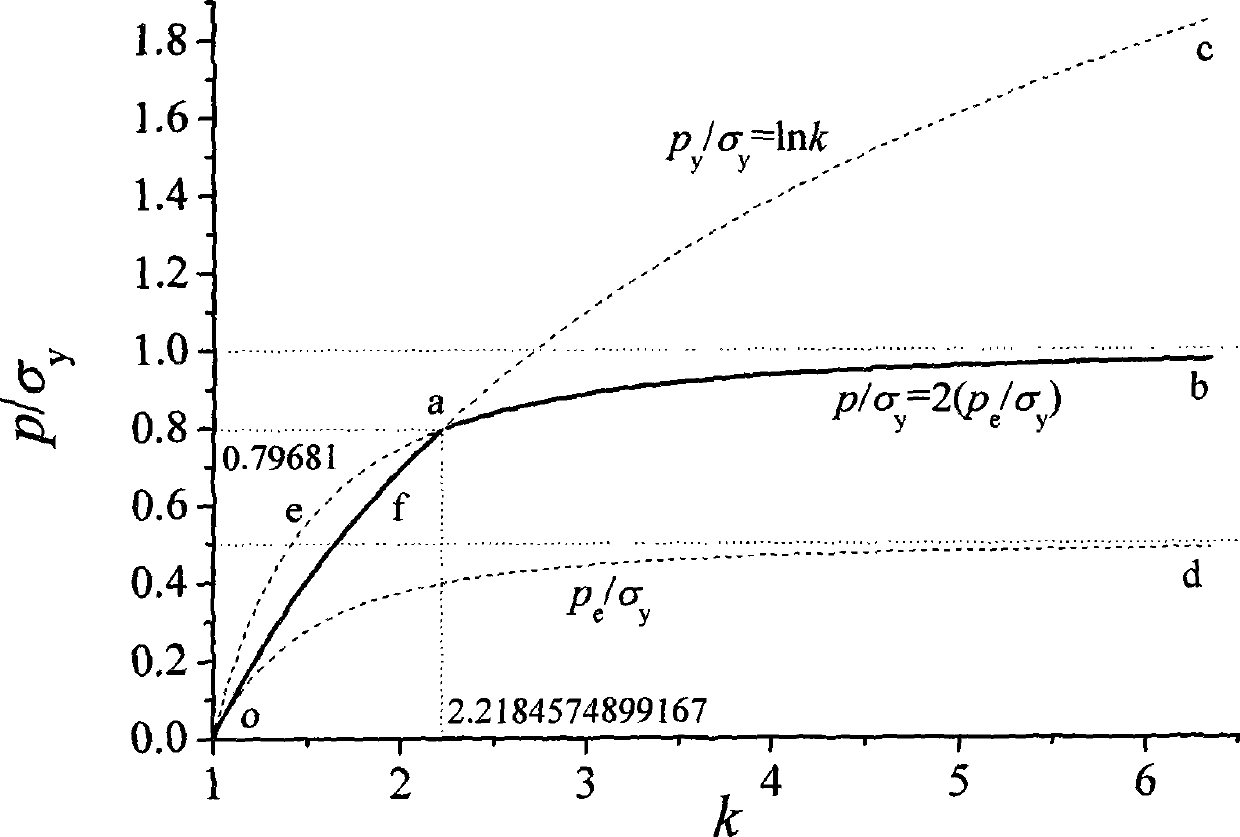

The present invention relates to a safe autofrettaged pressure vessel for improving the safety and bearing capability of the vessel and overcoming the technical problem such as unsafety which maybe caused by complex or imprecise calculation of the design of the prior art. The essential points of the technical scheme of the safe autofrettaged pressure vessel are as follows: the depth of a plastic area is calculated according to a formula: k<2>lnk2<j> - k<2> - k2<j> + 2=0, in order to ensure that reverse yield cannot be generated; the bearing capability is calculated according to the graphic formula: P / sigma y =(k<2>-1) / k<2> or P / sigma y =2*(k<2>-1) / (3<1 / 2>*k<2>), in order to ensure Sigma ej <= Sigma y and Sigma ei <= Sigma y, wherein, k is a ratio between external and internal radiuses of the safe autofrettaged pressure vessel; k<j> is a radio between the radius of an elastic-plastic interface and the internal radius; sigma y is a yield strength of the material; p is an internal pressure borne by the vessel; pe is the maximum elastic bearing capability of a non-autofrettaged vessel; Sigma ej is an equivalent stress of a total stress at the elastic-plastic interface; Sigma ei is the equivalent stress of the total stress at the inner wall surface. When k is less than a value determined by a formula of (k<2> / (k<2>-1))*lnk=1, no matter how large the k<j> is, the container cannot generate reverse yield after autofrettaged pressure is released, and at the moment, the maximum bearing capability of the autofrettaged vessel can reach the full yield pressure, namely the formula of p / sigma y =lnk or p / sigma y =(2 / (3<1 / 2>))*lnk.

Owner:朱瑞林

PPR/EVOH/POE (Pentatricopeptide Repeats/Ethylene-Vinyl Alcohol/Polyolefin Elastomer) blending high-impact barrier pipe and manufacturing method thereof

ActiveCN102002191BHigh mechanical strengthExcellent gas barrier performanceRigid pipesElastomerPolyolefin

The invention discloses a PPR / EVOH / POE (Pentatricopeptide Repeats / Ethylene-Vinyl Alcohol / Polyolefin Elastomer) blending high-impact barrier pipe and a manufacturing method thereof, belonging to the field of novel polymeric composite materials. A blending system is formed through physical blending by compositely using PPR, EVOH and POE and compatibilization is carried out on the blending system byadopting a PP-g-MAH (Polypropylene-grafting-Maleic Anhydride) nucleating agent, thus the problems of low temperature brittleness, oxygen and permeability resistance, corrosion resistance, ageing resistance, heat resistance, processability, and the like of a PPR pipe are effectively solved. The PPR / EVOH / POE blending high-impact barrier pipe has the following performances that: drawing yield pressure is 48 MPa, the impact strength of a freely supported beam is 3.6 KJ / m<2>, and oil absorption rate is 0.5%, longitudinal retraction rate is 1%; seepage and crack do not exist in hydrostatic tests and heat stability tests in hydrostatic states; and the PPR / EVOH / POE blending high-impact barrier pipe meets the safety evaluation criterion of domestic drinking water delivery and distribution equipment and protective materials. The invention can be widely applied to the fields of municipal and building water supply, heating, gas supply, electric power, communication, industry, agriculture, and thelike.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

High oil peanut quality breeding method

InactiveCN1276707CThe technical method is simpleGood characterPlant genotype modificationMicrobiologyYield pressure

The invention provides a high oil peanut quality breeding method which comprises, combining parental generation combination by selecting seeds with good comprehensiveness and high oil content, selecting fine strains at early stage generation, which is high yield pressure screen selecting, determining oil content in each seed of the single strain, screening seeds with high oil content for cultivation on next generation, which is high oil pressure screening, finally selecting fine single strain and determining oil content for each seed of the fine single strain for different separated generations, and accomplishing high yield and high oil pressure selection and oriental cultivation.

Owner:CROP RES INST GUANGDONG ACAD OF AGRI SCI

Breeding method for high-oleic acid high-yield peanut

InactiveCN101513170BGood characterImprove efficiencyPlant genotype modificationAngiosperms/flowering plantsSocial benefitsAgricultural science

The invention provides a breeding method for high-oleic acid high-yield peanut, which includes steps: (1) coordinate parent combination: selecting high-yield germplasm with good integrated character and germplasm with high oleic acid content SPI098 to combine patent; (2) high oleic acid pressure screening: determining oleic acid of each seed in excellent single plant in early separation generation, and selecting excellent peanut seed with high oleic acid content; (3) high-yield pressure screening: planting the screened peanut seed with high oleic acid content in next generation, separating generation in anaphase, and selecting excellent high-yield single plant; and (4) high-oleic acid high-yield peanut variety or strain obtaining: obtaining novel high-oleic acid high-yield peanut variety or strain through multi-generation high-oleic acid high-yield pressure screening. The breeding method provided by the present invention directly screens according to character of oleic acid content inpeanut seed, and has advantages of short breeding period, small blindness, high efficiency, and good economic benefit and social benefit.

Owner:SHANDONG PEANUT RES INST

Construction method of walling and filling combined gob-side entry retaining wall body

Owner:CHINA UNIV OF MINING & TECH

Pipe thread joint

A threaded joint which economically imparts effective sealing properties to a metal-to-metal seal portion and which can prevent seizing at the time of make-up comprises a steel pipe 1 having at its tip a male thread 1 b and an unthreaded sealing surface 1 a, and a coupling 2 having on its inner surface a female thread 2 b and an unthreaded sealing surface 2 a. With the yield pressure of the inner surface of the pipe being Py, (1) the average pressure Pm of the annular contact portion satisfies Pm / Py>=3, and the width in the axial direction of the portion which receives a pressure Ps which satisfies Ps / Py>=1 in the annular contact portion is at least 1 mm (or at least 2 mm), and the surface roughness Ry of both unthreaded sealing surfaces is at most 25 mum (or at most 30 mum), or (2) the relationship between the average pressure Pm of the annular contact portion and the surface roughness Ry (mum) of the unthreaded sealing surface satisfies Pm / Py>=0.0032xRy2+1.0, and the width in the axial direction of the portion which receives a pressure Ps which satisfies Ps / Py>=1 in the annular contact portion is at least 1 mm.

Owner:NIPPON STEEL CORP

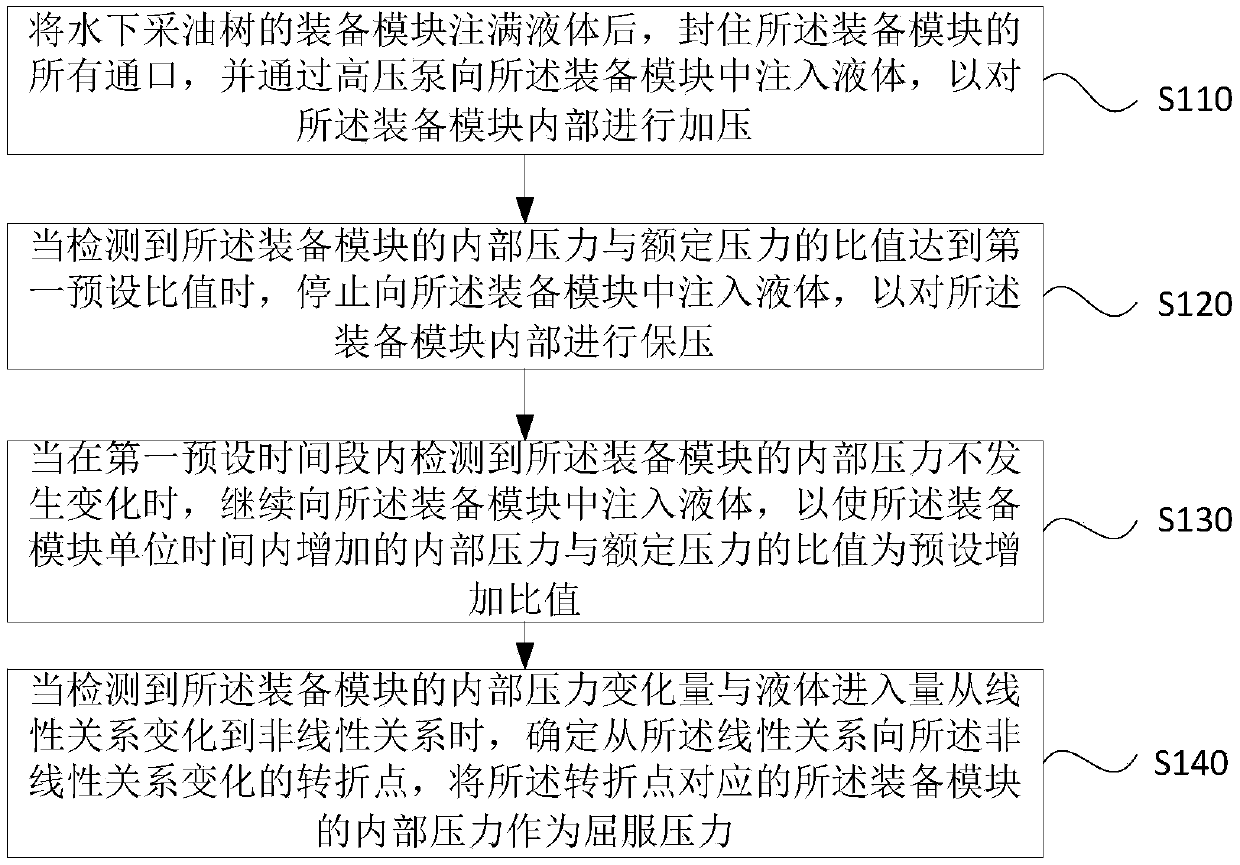

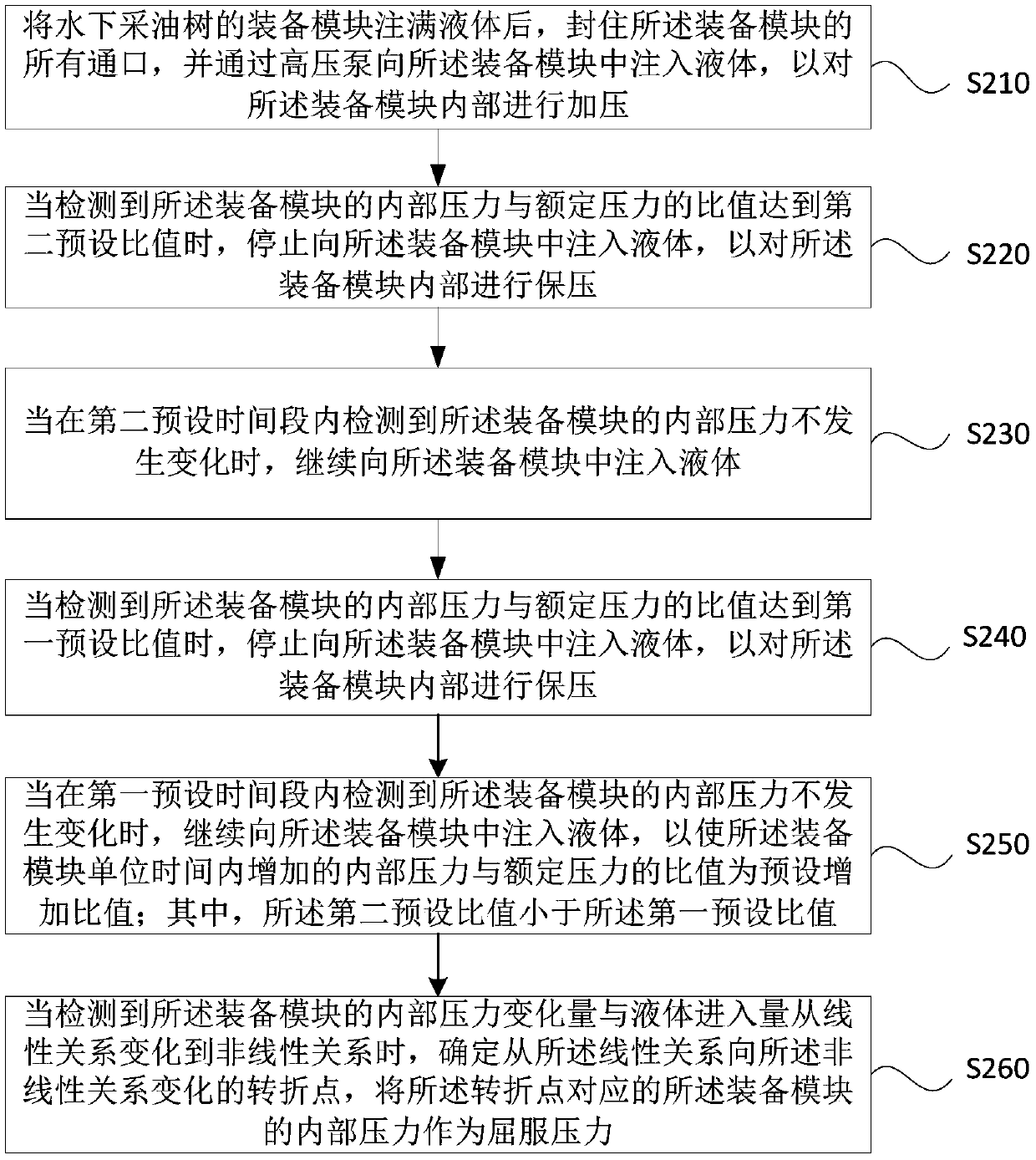

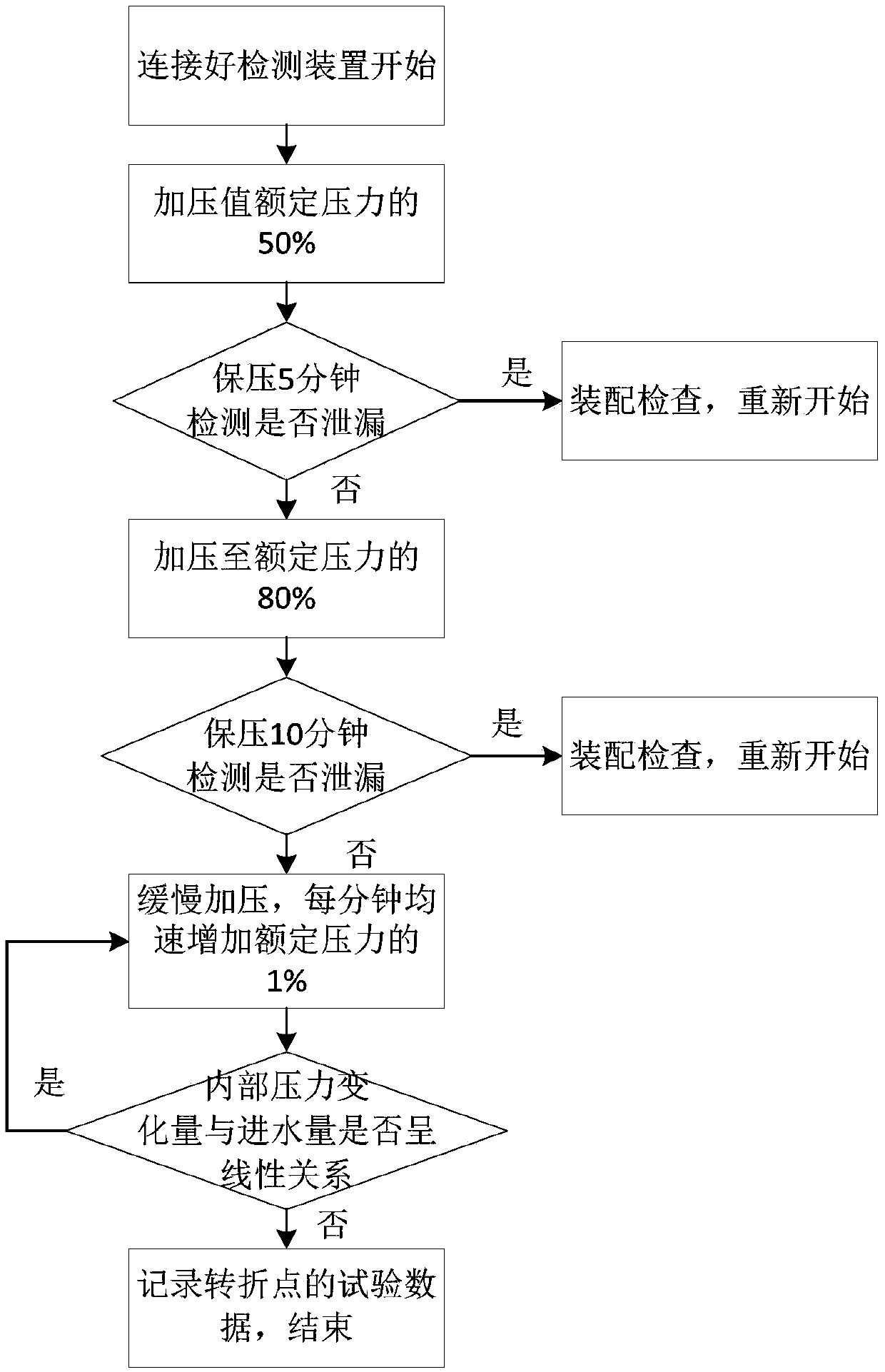

Equipment module yield pressure detection method and device of underwater Christmas tree

An embodiment of the invention provides an equipment module yield pressure detection method and device of an underwater Christmas tree. The method includes: filling an equipment module of the underwater Christmas tree with liquid, sealing a port of the equipment module, and injecting liquid into the equipment module through a high-pressure pump; when a ratio of inside pressure of the equipment module to rated pressure is a first preset ratio, stopping injecting the liquid; when the circumstance that the inside pressure of the equipment module does not change is detected within a first preset time period, continuing injecting the liquid into the equipment module to enable a ratio of the inside pressure increased within unit time of the equipment module to the rated pressure to be a preset increase ratio; determining inside pressure changing amount and liquid entering amount of the equipment module to determine a turning point from a linear relation to a nonlinear relation, and taking inside pressure corresponding to the turning point as yield pressure, Performance testing of the underwater Christmas tree can be improved, and a guarantee can be provided for long-time, stable and safeworking of the underwater Christmas tree.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD

Circumferentially compressible composite well wall and construction method thereof

ActiveCN102011592BUniform radial stress distributionImprove hoop carrying capacityUnderground chambersTunnel liningStructural engineeringYield pressure

The invention provides a circumferentially compressible composite well wall and a construction method thereof which are most applicable to improving the bearing capability of a vertical well wall. The composite well wall comprises a waterproof outer well wall and a circumferentially compressible inner well wall; and the inner wall is provided with at least one compressible insulating layer. In the construction method, firstly, the waterproof outer well wall is built from top to bottom according to the section height; then the inner wall embedded with the compressible insulating layer is builtfrom bottom to top; and finally the wall is built to the designed height according to the section height. When water and soil pressure effects surrounding the composite well wall, the compressible insulating layer of the inner well wall is compressed for yielding pressure so as to enable the stress to be distributed more evenly along the radial direction of the well wall, thus effectively improving the bearing capability of the well wall, effectively reducing the thickness of the existing well wall, improving the utilization ratio of the shaft section, and reducing the engineering cost to a large extent.

Owner:CHINA UNIV OF MINING & TECH

A constant-strength self-reinforcing pressure vessel with variable structural dimensions

InactiveCN103470757BSafe and reliable structureReduce wall thicknessPressure vesselsManufacturing cost reductionInternal pressure

The invention provides an equal-strength self-enhancement pressure vessel with the variable structure size, and aims to improve safety of the pressure vessel, reduce manufacturing cost and solve the technical problems that in the prior art, calculation is complicated and inaccurate, and a vessel is unequal in strength, fixed and unreasonable in structure, and inflexible in design. The equal-strength self-enhancement pressure vessel has the advantages that under the condition that loads are unchanged, the structure size is flexible and changeable, and the equal-strength structure is achieved (the total stress in a plastic zone is constant and the total stress of an elastic zone is constantly smaller than yield strength). According to the technical scheme, when the diameter ratio k is larger than the kc lambada value which is determined by a formula, the superstrain degree epsilon lambada of the vessel is determined according to another formula: k21n (epsilon lambada (k-1) +1) 2-(lambada -1) k2-(epsilon lambada (k-1) +1) 2 +lambada=0, and the internal pressure p of the vessel is lambada times of the initial yield load pe of a vessel with the same size and free of self-enhancement; when k is smaller than or equal to the kc lambada value which is determined by the formula, the superstrain degree of the vessel can be 100%, and in the self-enhancement pressure vessel of which maximum bearing capacity can be total yield pressure or of the structure, all the stress of the vessel is within a safety range. The diameter ratio k is the ratio of the external radius of the vessel to the internal diameter of the vessel.

Owner:HUNAN NORMAL UNIVERSITY

Spinning spinneret

InactiveCN104593879AImprove stabilityImprove deformationSpinnerette packsSpinning head liquid feederAir volumeEngineering

The invention discloses a spinning spinneret. The spinneret comprises a gooseneck, one end of the gooseneck is provided with a spinneret component, the upper portion of the other end of the gooseneck is provided with a pressure sensor, the spinneret component comprises a spinneret plate arranged at the front portion and locking pieces connected with the spinneret plate, a spinneret orifice and gas orifices are formed in the spinneret component, and the gas orifices are located at the periphery of the spinneret orifice. According to the spinning spinneret, on the premise that filament yielding pressure is effectively controlled through the pressure sensor, air injection is conducted toward filaments at the same time of filament yielding, along with increasement of the air volume and the flow velocity, the deformation of a filament bundle can be good and the bulkiness can be improved, in addition, adhesion between spinning solution and the spinneret plate can be effectively reduced, the possibility that the spinning solution spreads along the spinneret plate is reduced, the spinning stability is improved, and performances of protofilaments are enhanced.

Owner:SUZHOU CITY WUZHONG DISTRICT GUOXIANG XUYU WOOLENSWEATER PROCESSING PLANT

A reinforced U-shaped steel bracket that can be pressed

ActiveCN106812544BPrevent bucklingPrevent collapseUnderground chambersTunnel liningStructural engineeringYield pressure

The invention relates to a reinforced yielding U-shaped steel bracket which comprises first support section steel vertically arranged on two sides of a roadway, wherein second support section steel for supporting surrounding rocks at the cambered top of the roadway is arranged at the upper ends of the first support section steel, and is bent into a curved structure; two ends of the second support section steel are movably matched with the upper ends of the first support section steel in the vertical direction respectively; slip limiting yielding mechanisms for stopping the second support section steel moving downwards are arranged at the overlapping parts of the first and second support section steel. Such yielding U-shaped steel brackets can be arranged at intervals in the length direction of the roadway, and the pressure of the surrounding rocks at the top of the roadway is released and transmitted to the second support section steel, so that a sufficient yielding amount is provided for the surrounding rocks at the top of the roadway to avoid the condition that the U-shaped steel brackets reach the yield strength to cause buckling, kicking and collapsing of the U-shaped steel brackets, and further ensure effective support to the surrounding rocks at the cambered top of the roadway, and yielding pressure release and rigid support of the surrounding rocks at the cambered top of the roadway are realized.

Owner:ANHUI UNIV OF SCI & TECH

Pressure-yielding anchor device

ActiveCN102182182BMechanical properties unchangedDoes not affect the space outside the holeBridge structural detailsBulkheads/pilesEngineeringYield pressure

The invention discloses a pressure-yielding anchor device, which comprises an extrusion head, a pressure-yielding sleeve and anchor bars, wherein the extrusion head is a cylinder with the conical surface at the lower part and movably connected with the anchor bars into a whole; and the extrusion head is arranged in the pressure-yielding sleeve, the raised surface matched with the conical surface at the lower part of the extrusion head is arranged on the inner wall of the pressure-yielding sleeve, the pressure-yielding sleeve is a steel pipe with a raised edge on the inner wall preferably, and the raised surface matched with the conical surface of the extrusion head is arranged at the end part of the raised edge. By adopting the pressure-yielding anchor device, the purposes of yielding pressure, dissipating energy and controlling deformation can be realized during anchoring, and the pressure-yielding anchor device is applicable to the anchor bars made of any material. The pressure-yielding anchor device is convenient to manufacture, reliable in effects and applicable to different engineering needs.

Owner:杭州图强工程材料有限公司

Method for designing corrugated steel sheet, and corrugated steel sheet pipe

Provided is a method that is for designing a corrugated steel sheet and that is characterized by, when designing the corrugated shape of a corrugated steel sheet that configures a corrugated steel sheet pipe of tube diameter D comprising a corrugated steel sheet having corrugations having a wave depth of H, setting the wave depth (H) with respect to the tube diameter (D) in a manner so that, with the presumption that the corrugated steel sheet pipe will incur uniform external pressure at the outer surface, the annular buckling pressure (pcr) when the corrugated steel sheet pipe buckles and the yielding pressure (py) when the corrugated steel sheet pipe yields are equivalent.

Owner:NIPPON STEEL & SUMIKIN METAL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com