Safe self-reinforcing pressure vessel

A pressure vessel and safety technology, applied in the fields of chemical engineering and mechanical science and technology, can solve problems such as being too rough, cumbersome, and unable to reflect the essence of the problem, and achieve the effect of avoiding rough or cumbersome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

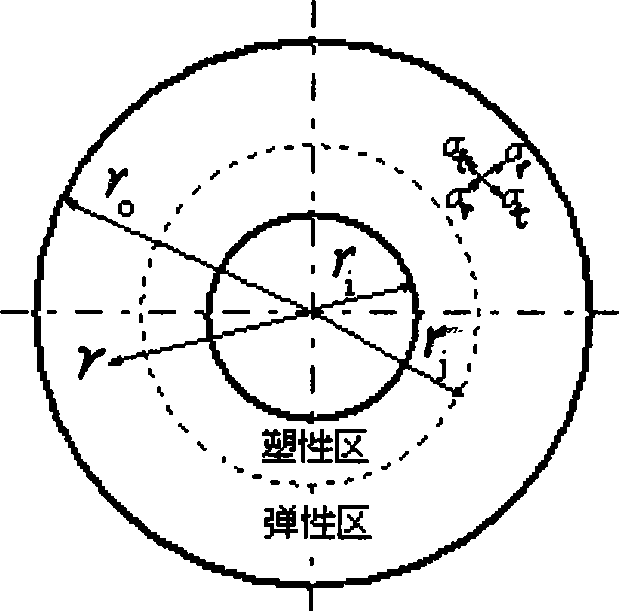

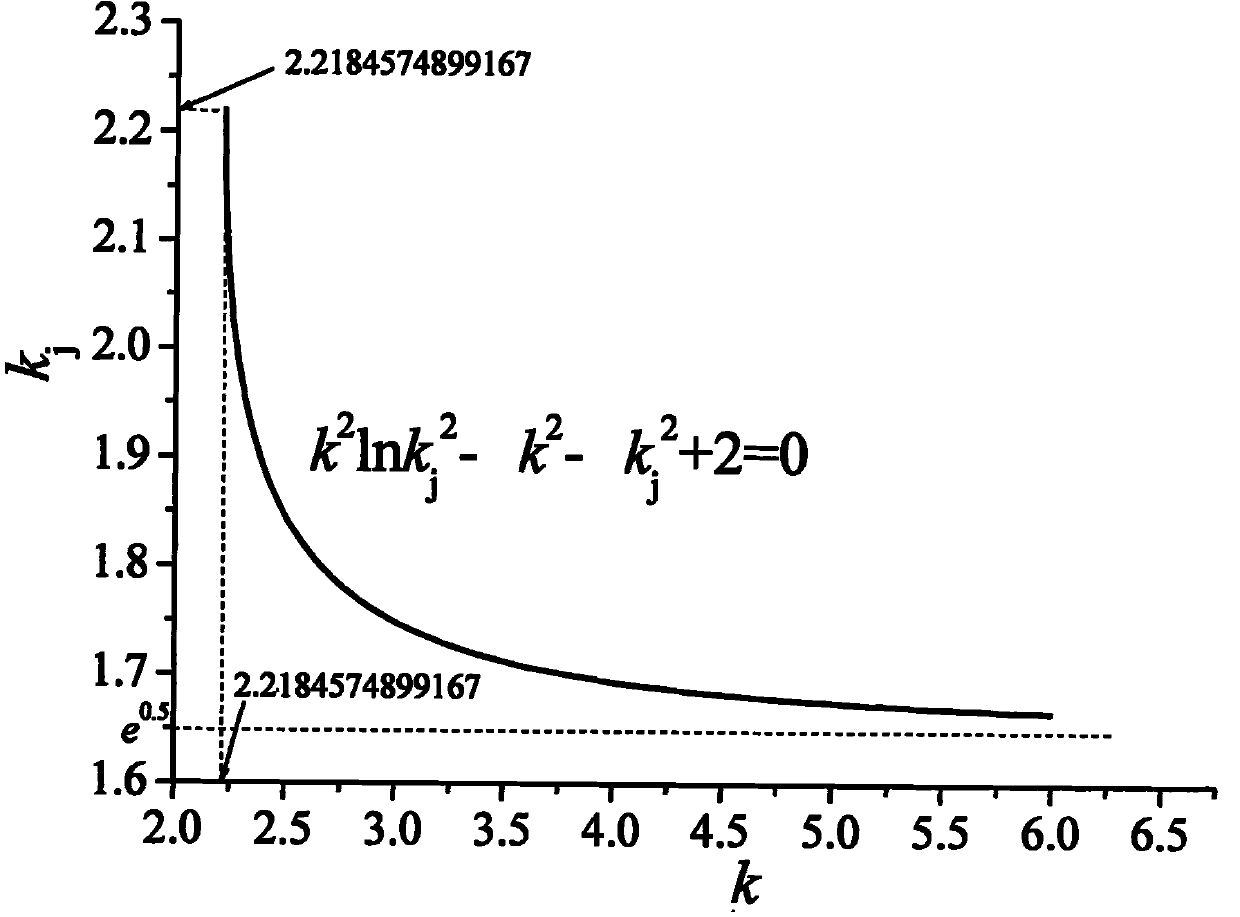

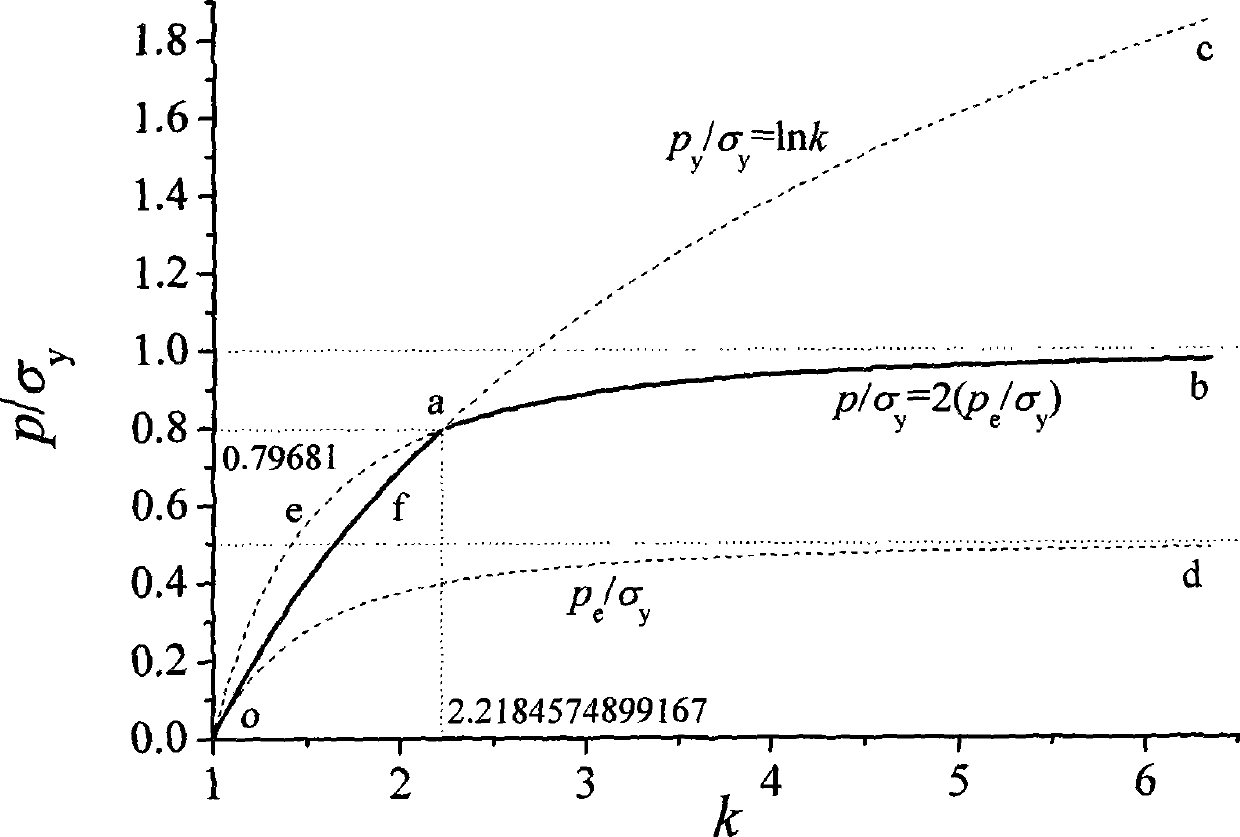

[0011] Example 1, the inner diameter r of the pressure vessel can be determined according to the process calculation i ; After the container material is determined according to the load it will bear (p / σ y ), according to the calculation formula of bearing capacity p σ y = k 2 - 1 k 2 (Third Intensity Theory) or p σ y = 2 k 2 - 1 3 k 2 (The fourth strength theory) can determine diameter ratio k (according to k=r o / r i The outer diameter r can be determined o ). After k is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com