Spinning spinneret

A spinneret and spinning technology, which is applied to the spinneret assembly, feeding solution to the spinneret, textiles and papermaking, etc., can solve the problems of nozzle deformation, hairy filaments, high defects, etc., and achieve good deformation, The effect of faster flow rate and higher bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

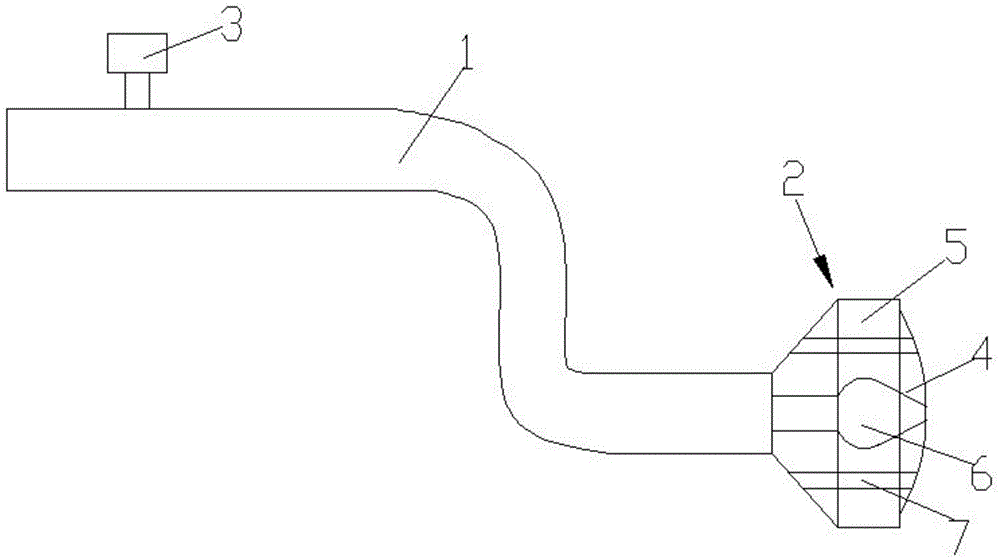

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 The illustrated spinneret for spinning according to the present invention comprises a gooseneck 1, one end of the gooseneck 1 is provided with a spinneret 2, and the upper part of the other end is provided with a pressure sensor 3. The silk part 2 includes a spinneret 5 arranged at the front and a locking member 5 connected to the spinneret 5, and the spinneret 2 has a spinneret hole 6 and an air jet hole 7 inside, and the air jet hole 7 is in the spraying position. The periphery of the wire hole 6; the spinneret 4 is an outwardly expanding arc-shaped plate, which can withstand greater working pressure and is not easily deformed; the spinneret 4 is made of beryllium copper material, which has high working strength and is not easy to deform. The spinneret for spinning according to the solution of the present invention, on the premise that the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com