Pipe thread joint

A technology for threaded joints and pipes, applied in threaded connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as sealing performance, leakage, and wear regardless of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

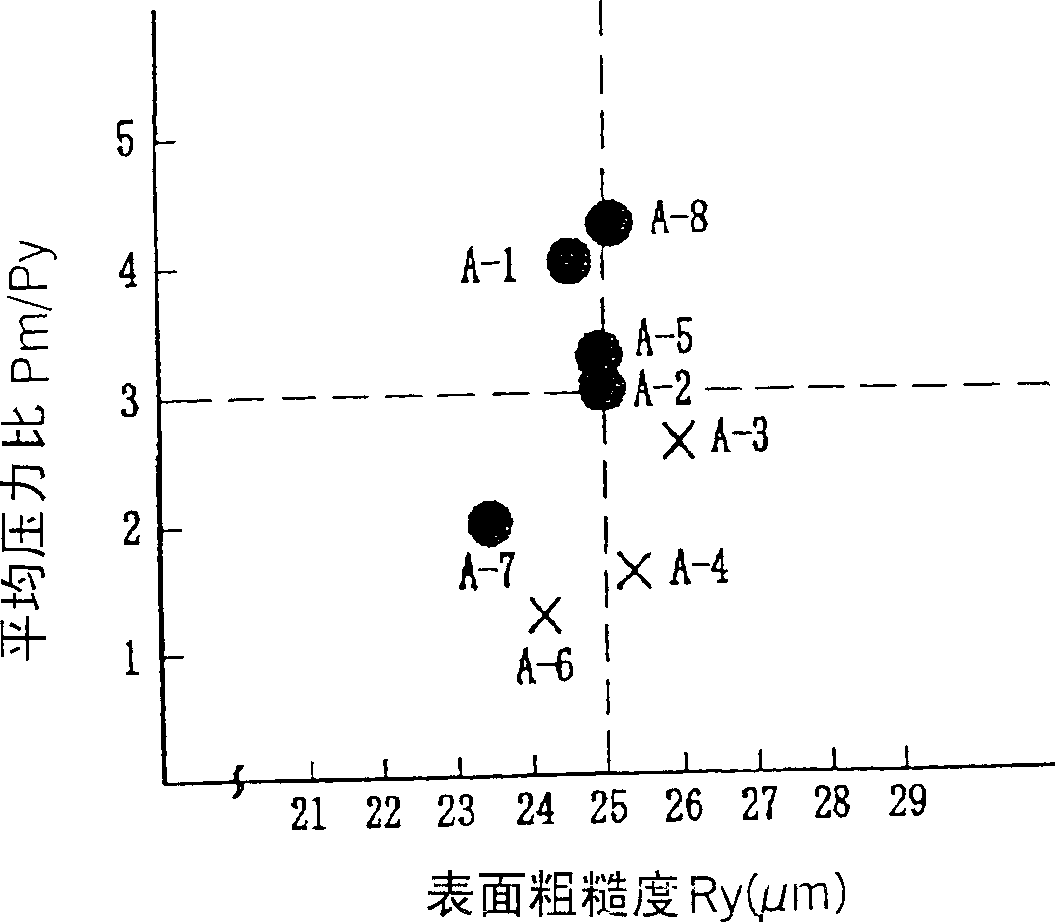

[0074] Using the aforementioned test pipes and connectors of the same size and same material, prepare threaded joints for various tests (samples), and use the aforementioned same sealing test to study the sealing performance.

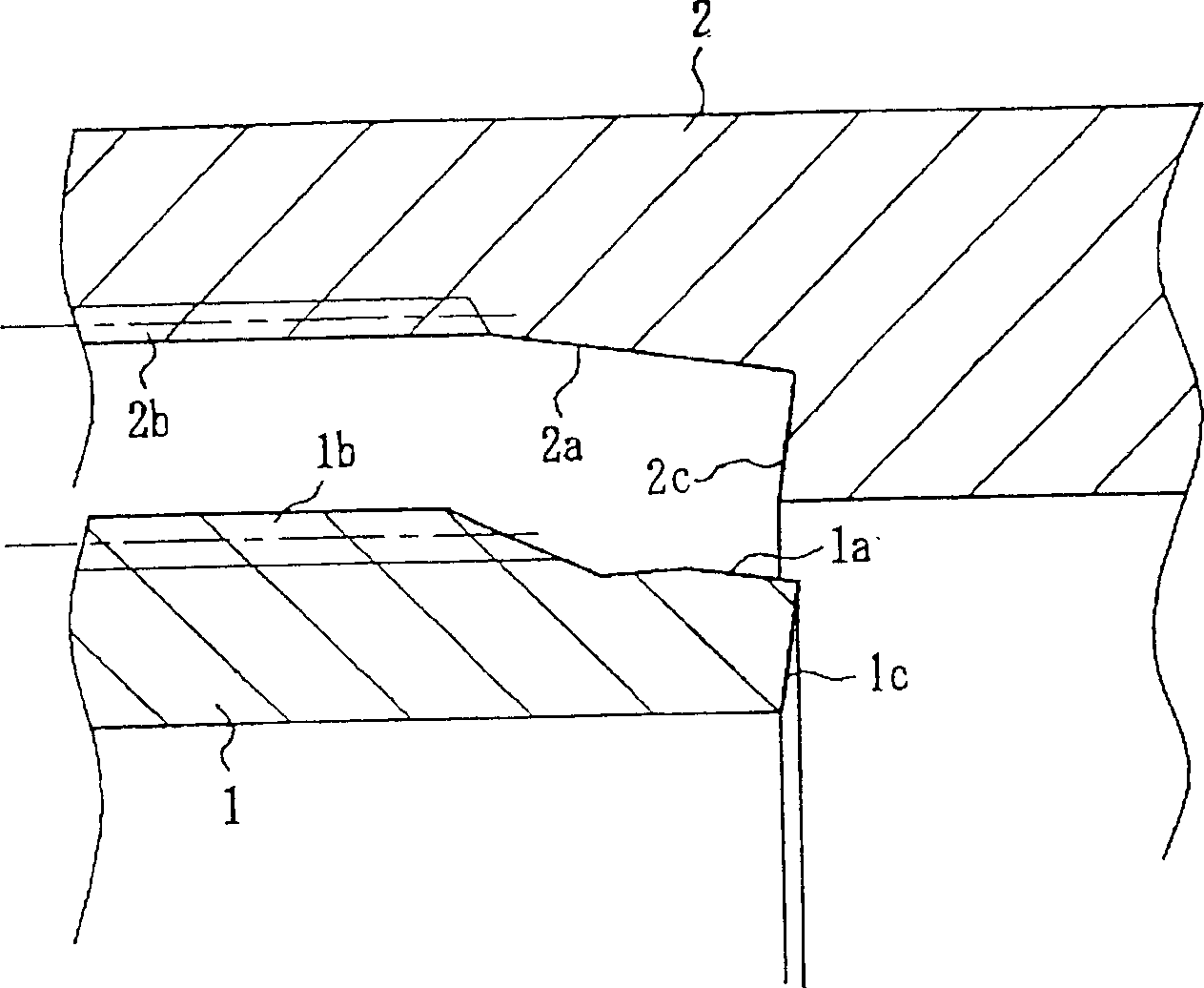

[0075]Each sample was prepared so that the average pressure ratio Pm / Py and the surface roughness Ry of the unthreaded sealing surfaces 1a and 2a of the test pipes and connectors had the values shown in Table 4, respectively. Make the amount of interference of the thread zero, so it has no effect on the sealing portion, and stop tightening when the shoulder 1c abuts.

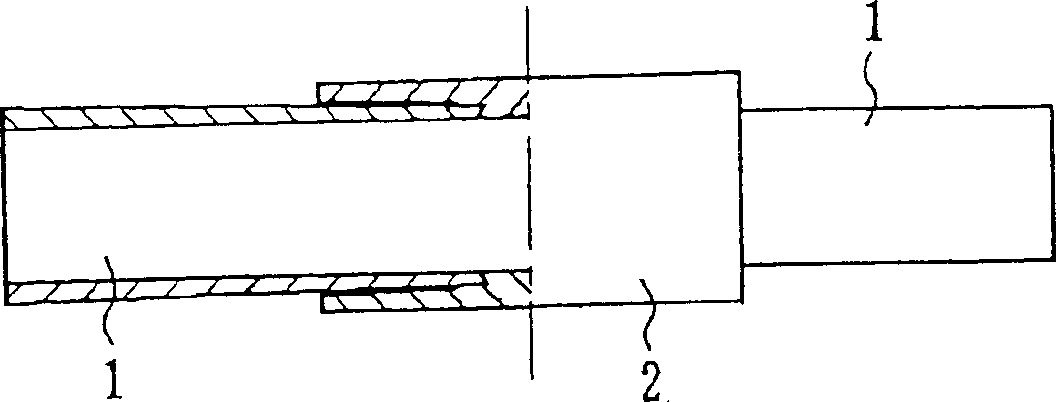

[0076] Such as figure 1 As shown, the sample has two test pipes 1, each of which has a male thread 1b and a non-threaded sealing surface 1a formed on the peripheral surface of the end points placed at both ends of the connector 2, and the connector 2 has an inner peripheral surface at both ends Formed female thread 2b and non-threaded sealing surface 2a. Thus, each sample has two thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com